Shandong Nanshan Aluminum Co., Ltd. is expanding its aluminum plant in Longkou, Shandong province, China. The company manufactures aluminum sheet for the domestic and international markets. The expansion project will enable the company to grow its presence in the automotive and aerospace markets.

As part of its expansion project, Shandong Nanshan ordered a new cold rolling mill with universal crown-control mill (UCM) technology from Primetals Technologies, which will provide the mechanical and automation scope, engineering, and advisory services for the implementation. The new mill will be able to process aluminum strip in thicknesses of 0.2–6.0 mm and widths of 1,000–2,200 mm. It will provide an annual capacity of about 180,000 tons — representing a pivotal part of Shandong Nanshan’s future growth strategy and its shift toward the automotive market.

The automation solution for the cold mill comprises basic automation (Level 1) and advanced process optimization systems (Level 2), as well as motors, a complete drive system, and electrics parts. The mill will feature various shape control actuators like work roll bending, intermediate roll bending, intermediate roll shifting, and a precise spot cooling system. Thanks to this wide range of shape control measures, Shandong Nanshan will be able to execute all cold rolling processes on the mill using the same type of straight crown work rolls. This will result in reduced costs for spare work rolls.

The UCM solution is well-known for high rolling stability and detailed shape controllability. The intermediate roll is shifted axially in the roll direction, depending on strip width. Therefore, any undesirable contact between the work and backup rolls is prevented.

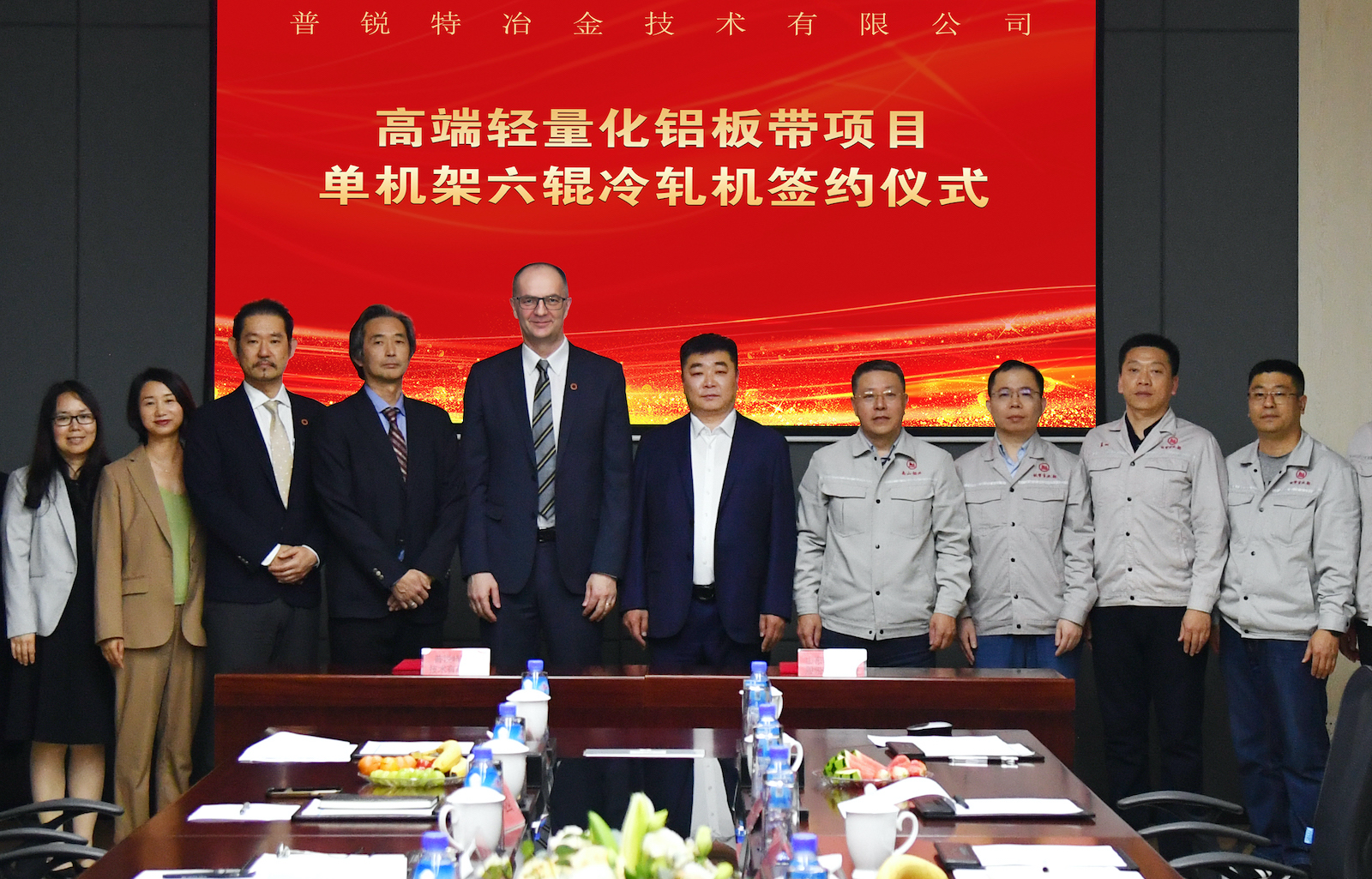

ceremony.

In addition to the new cold mill, Shandong Nanshan placed an order for two continuous heat treatment lines (No. 3 and No. 4) and one continuous process treatment line (No. 4) from ANDRITZ. The scope of supply includes engineering, equipment supply, supervision of erection, and commissioning of the complete lines, including the electrical and automation equipment.

“The ANDRITZ well-proven technology, focusing on excellent aluminum process lines, and the extensive local network of experts and service specialists in China were key factors why ANDRITZ received the order from Nanshan,” said Wang Tao, director of the Shandong Nanshan production plant in Longkou.

Start up of the new equipment will take place in 2025.