LOTTE Aluminium Materials USA LLC is investing in the construction of a new aluminum foil production plant in Kentucky, as part of a project announced in August 2022. As part of its strategic expansion plans, the new facility will focus on the production of cathode foil, a type of ultra-thin aluminum foil that is a core material used in electric vehicle (EV) batteries.

The LOTTE group is one of the largest conglomerates in South Korea and employs more than 80,000 people in over 90 business units worldwide. The group’s highly diversified product portfolio includes aluminum foil, printed packaging materials, and corrugated cardboard boxes, as well as basic chemicals and highly advanced materials such as polymers, monomers, and petrochemical feedstocks.

With the construction of its new aluminum facility in Kentucky, the LOTTE group aims to produce 36,000 tons of cathode foils annually to meet the sharp increase in demand from the EV market. Aluminum cathode foils are used, for example, in the production of lithium-ion batteries for electric cars.

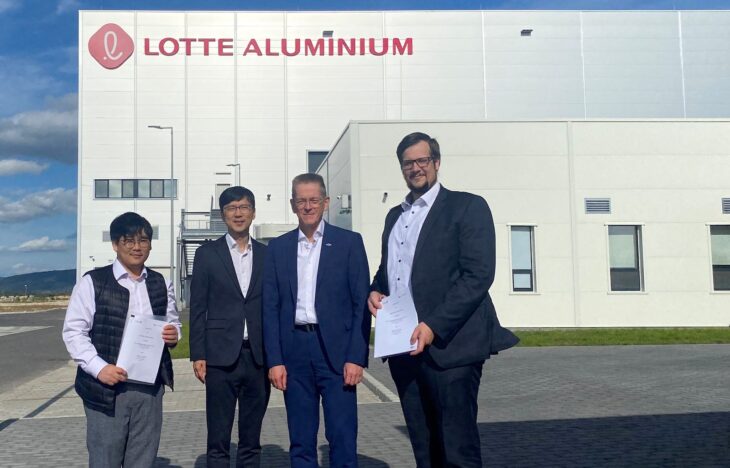

A core aspect of the new Kentucky plant will be its logistics and storage system, which will be supplied by AMOVA, a subsidiary of SMS group. The contract includes the supply of a smart, fully automated high-bay store with transport system.

The high-bay storage system, which has around 500 storage spaces, will be connected to the various process lines through the relevant conveying equipment. The new high-bay storage system will accommodate very thin-rolled, sensitive coils of cathode foil on paper and steel spools, as well as separator racks.

Applying its decades of experience, SMS worked closely with the customer to develop an ideal solution tailored to its needs. During the project planning phase, SMS was faced with the challenge of developing a system that could handle the kind thin and sensitive materials that LOTTE would be producing with as much flexibility as possible. With the cantilever system (load-carrying beam supported at one end), all products can be supplied damage-free to the next stage in the process.

LOTTE is relying on SMS’s digitalization expertise and rounding off its portfolio with the warehouse management software. This software, specially developed over decades, is a core component of the high-bay storage systems and is subject to continual optimization to ensure end-to-end material tracking and user-friendly visualization.

The new logistics and storage system is scheduled to go into service at the end of 2024.