Viva Aluminium Systems, a Vias Group member, installed a new nitriding furnace for the processing of extrusion dies at its facility in Shumen, Bulgaria. With the company experiencing increased demand, it decided to invest in the expansion of its manufacturing capacity. The installation of a new nitriding furnace was a part of a larger expansion that also included a new extrusion press line.

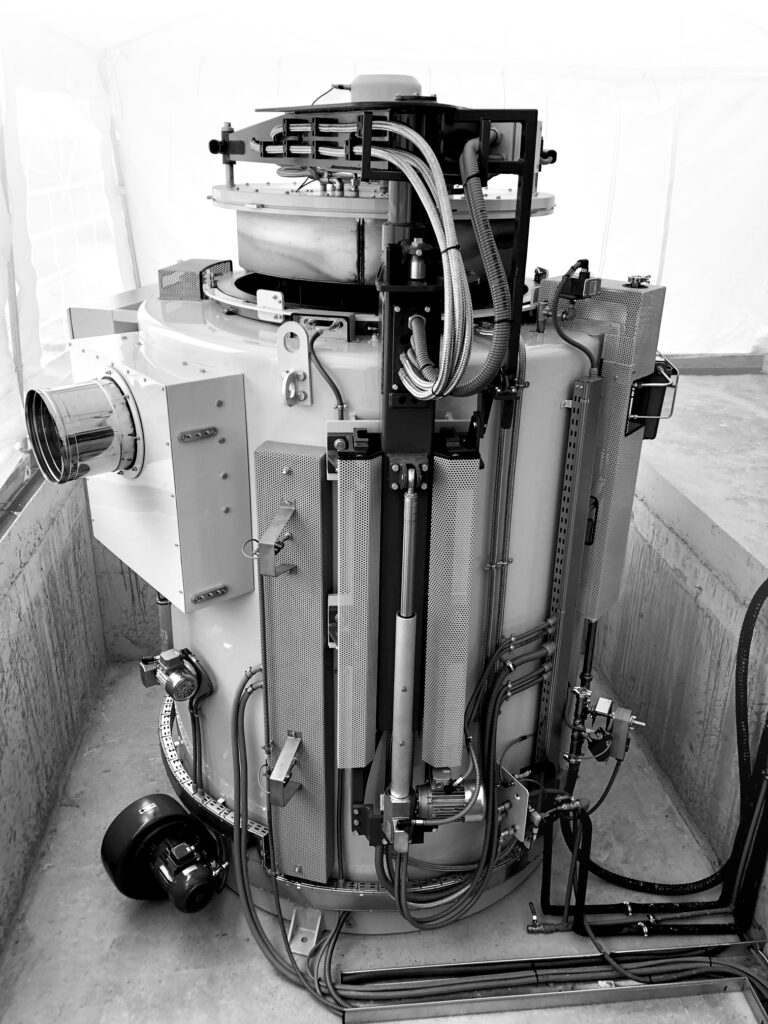

The NX-1015 turnkey furnace for nitriding extrusion dies was supplied by Nitrex — making it the second nitriding system provided by the supplier. The new pit furnace has an effective work zone that is 39 inches in diameter by 59 inches high (1,000 x 1,500 mm) with the capacity to nitride a 4,400 lbs (2,000 kg) load.

The system includes Nitreg® process technology, which adapts to the application requirements in order to deliver improved performance for the extrusion dies. This makes it possible to achieve a higher throughput per extrusion run. It also enables a higher number of runs per treated die, which in turn optimizes tool life and lowers tooling cost for a faster return on investment.

The turnkey system also features a Nitrex HMI configured with multiple languages including other integral hardware, such as a high-efficiency eco-friendly neutralizer, an H2Smart™ hydrogen sampling system, and SGS™ gas sensor for high accuracy readings of the nitriding atmosphere.

“We are delighted to do business with Viva again,” stated Marcin Stoklosa, product manager at Nitrex. “Fostering customer loyalty is a top priority at Nitrex and key to building an ongoing partnership for future growth. This is the second Nitrex system at the company’s facility in Bulgaria, and while it confirms the continued market demand for Viva aluminum extruded profiles in Europe, it is also a clear sign that Nitrex nitriding system is providing Viva with batch-to-batch production consistency and repeatable product quality in the manufacturing of extruded parts.”