Vitex Extrusion, a division of Momentum Manufacturing Group, plans to invest $12 million in the first phase of a new aluminum extrusion press line for its Franklin, New Hampshire, facility. The investment will double the extruder’s current output to 55 million lbs and support growing demand from customers and partners for aluminum extrusions and value-added components.

“We see continued demand from new and existing customers across all industries for custom extruded profiles, as well as expanded downstream, value-added manufacturing process requirements, including precision machining, fabrication, laser tube cutting, automated welding, and assembly,” said Andrew Curland, president of Vitex Extrusion. “The new press line enables us to address this demand and support future growth plans for the company.”

New Press Line

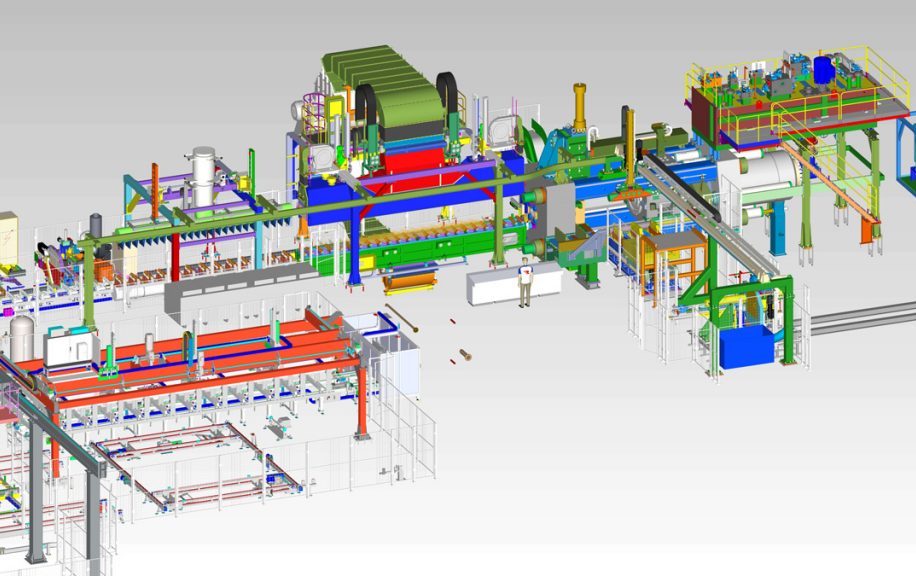

The first phase of the expansion will include the installation of a 2,750-ton, 8-inch press line from Italy-based Presezzi Extrusion Group. The press line will include the Presezzi ESS energy-saving system (which provides a 35% reduction in energy requirements compared to many existing systems); a six-stage, energy-efficient tapered aluminum billet furnace; a two-stage post extrusion quench system with enhanced, distortion-free cooling; a high-precision double-stage finish saw; and post-extrusion handling to the aging operation. The entire line will feature the latest mechanical and automation technologies, as well as advanced safety features.

The new extrusion line is expected to be operational in December 2021.

The project’s second phase will commence in late 2022 and include additional aging capacity, automated overhead crane movement, and automated packaging. Vitex will partner with Presezzi and Belco Industries for the new equipment and planning for the second stage of the expansion project.

Ongoing Investments

Vitex has been investing in and modernizing its Franklin facility for the past 13 years. Initial stages focused on developing value-added fabrication and machining services to support its electronics, solar, sporting goods, furniture, Tier 2 automotive suppliers, and building and construction customers. In 2010, Vitex selected Presezzi Extrusion for its first 8-inch press to replace an aging 7-inch press.

Over the last ten years, more than $18 million has been invested in a state-of-the-art quench system; automated profile stacking, handling, and packing systems; and additional CNC machines for greater value-added capabilities. In 2020, the company’s value-added business was moved into a dedicated 50,000 sq ft facility, adjoining the company’s Franklin campus.