Hydro is partnering with Reliefed Technologies to research and develop new 3D solutions in aluminum. The project will focus on providing greater design freedom and more efficient use of resources and energy.

“It is vital for Reliefed to team up with strategic partners who have the focus and mindset that refuses to accept status quo,” said Mikael Eklund, CEO of Reliefed Technologies. “Hydro’s strong position and the common ground shared in terms of finding innovative solutions for a sustainable future, sets the basis for a successful cooperation, which we are really excited about.”

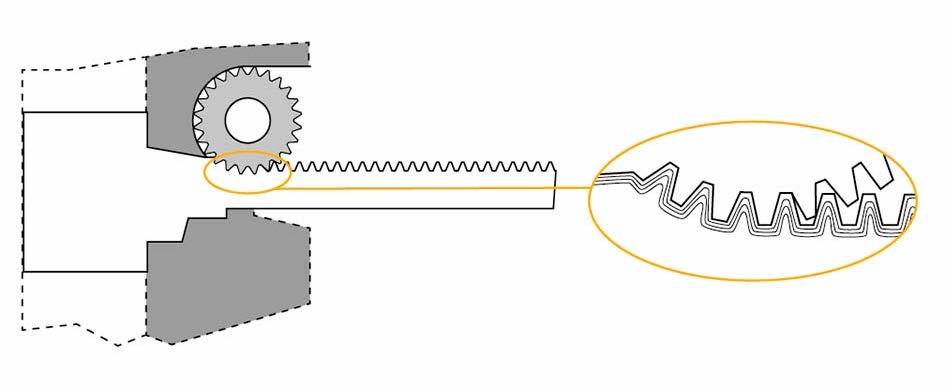

The project will focus on utilizing 3D-iExtrusion® technology, developed and patented by Reliefed, to provide design solutions for aluminum extrusions. Previously, in order to create a 3D pattern on a 2D profile, the extrusion had to be machined or stamped/formed in a separate operation. This technology enables a profile to be extruded in a standard press, but includes dies that rotate on the third axis, imprinting three dimensional details on the aluminum profile.

The technology enables new design and product development solutions as well as cost and energy-efficient 3D mass production for a variety of components and products. “Our 3D-iExtrusion technology is a game changer for completely new product solutions in a rational, resource and energy-efficient way,” said Eklund. “We have identified potential and see value for our customers in several product areas. We look forward to exploring these opportunities together.”

The 12-month research project will design and execute 3D extrusion tests of a conceptual application profile, with some of the activities to be carried out at Hydro’s aluminum research lab in Finspång, Sweden, which recently expanded its extrusion research capabilities.

As with Reliefed, Hydro is also working to shape a sustainable future through innovative aluminum solutions. “Our desire to stay in the innovative forefront and to unite competencies with external partners has opened for this collaboration,” said Ole Daaland, vice president Innovations & Technology, Hydro Extruded Solutions. He also stated that if the project shows a positive outcome — including achievement of a continuously stable 3D extrusion process — then the two partners will examine the potential for commercializing the process.