Hydro opened an aluminum research lab in Finspång, Sweden, where it will test new types of aluminum alloys and their extrudability for eventual use in innovative applications that can help customers reduce their carbon footprint. The investment extends and complements the company’s global research and product application capabilities toward the growing market for sustainable aluminum solutions.

“Research and application development has always been one of our strong points as a supplier of innovative aluminum solutions,” said Egil Hogna, EVP responsible for Hydro’s Extruded Solutions business area. “With sustainability now the key word in our industry, we need to speed these efforts to meet market needs.”

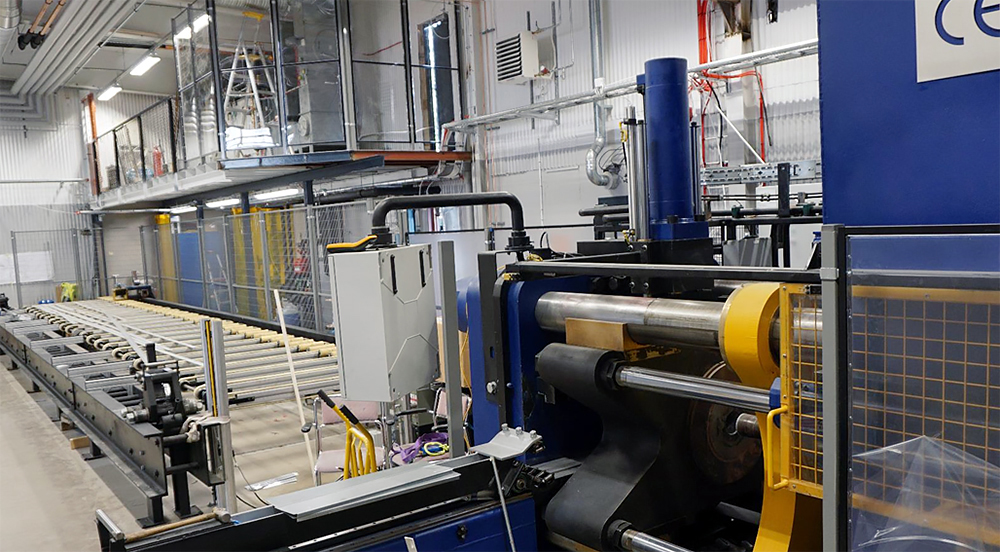

The new Extrusion Test Center includes a new aluminum extrusion press and metal casting facilities. The extrusion press, delivered by Prizma Engineering, will allow Hydro to quickly run their tests, as well as enable the testing of extremely hard aluminum alloys, including 7000-series alloys. The melting furnace for casting will yield a large part of the metal supply used within the lab.

The Extrusion Test Center is located adjacent to Hydro’s product application lab at a pervious extrusion plant. It will be an integral part of the global Innovation & Technology (I&T) unit of Extruded Solutions, which includes the product application lab in Finspång and an automotive-focused research and development lab in Troy, Michigan. I&T also operates aluminum tubing corrosion laboratories in China and the United States.

The application lab in Finspång carries out robotic welding, hot metal gas forming, friction stir welding, thermal testing and the testing of components, such as crash testing of automotive systems. The test center will offer services that complement the work of the application lab, says Ole Daaland, who heads the I&T unit for Hydro. “This extends our offering and makes it possible for us to develop alloys and prototypes much faster and more efficiently,” he said.

Eight employees have been trained to also handle operations at the test center, which will begin taking on research projects later this year.