The ET Foundation announced the winners of the 2019 Aluminum Extrusion Design Competition. More than 90 students from high schools and universities around the world submitted entries for the opportunity to receive a cash scholarship. The winning students were recognized for designs showcasing the versatility and advantages of aluminum extrusions. Bonnell Aluminum sponsored the cash scholarships that all together totaled $8,500.00.

Judging of the entries was performed by David Asher, process optimization manager for Bonnell Aluminum; Dr. Joseph Benedyk, editor of Light Metal Age magazine and aluminum industry veteran; and Todd Boyer, Director of sales & marketing for Mid-States Aluminum.

First Place $3,000.00 Scholarship: Nest Bed

Åse Lilly Salamonsen from The Oslo School of Architecture and Design in Oslo, Norway designed a modular bed system for refugee camps. The Nest Bed contains two main extruded components, the corner piece and the side rails. The extruded profiles are shaped so that it’s possible to stack two beds on top of each other. The modular beds help ease floor crowding typical in refugee camps.

“This was a contender for the Sustainable Design Award but we felt this student’s idea deserved First Place,” said judge Asher regarding the details and overall concept of Salamonsen’s design. The judges agreed that the design was both timely and relevant to the current global refugee crisis. The bed is also inexpensive to produce and the extruded aluminum profiles make the bed lightweight and solid.

“This was a contender for the Sustainable Design Award but we felt this student’s idea deserved First Place,” said judge Asher regarding the details and overall concept of Salamonsen’s design. The judges agreed that the design was both timely and relevant to the current global refugee crisis. The bed is also inexpensive to produce and the extruded aluminum profiles make the bed lightweight and solid.

Today, a typical bed in refugee camps is an old mattress on the ground, and because of large amounts of refugees in one place, disease spreads quickly. The nest bed is easy to clean and rests above ground, preventing spreading of infection and increasing a refugee’s quality of life.

Second Place $2,000.00 Scholarship: Storm Shield

Storm Shield is an easy-to-install hurricane shutter system designed with extruded pieces. The L-shaped extrusions apply pressure to window or door frames to prepare in the event of a hurricane. Kenny Adams, Benjamin Siperek, Matthew Retault, and James Jaraczewski from Texas A&M University in College Station, Texas created the design as a team.

The Texas A&M team wanted to lower the cost of production for hurricane window/door protection options while offering an elegant solution to high wind protection. The extruded pieces apply pressure to the upper and lower window/door frame. Plywood or sheet metal is supported by the compression applied.

The Texas A&M team wanted to lower the cost of production for hurricane window/door protection options while offering an elegant solution to high wind protection. The extruded pieces apply pressure to the upper and lower window/door frame. Plywood or sheet metal is supported by the compression applied.

All extruded components of the Storm Shield design are made of 6063 aluminum. The 6063 alloy was chosen because of its high strength, resistance to corrosion, and its extrudability.

“This product solves a real problem and there is a big market for it. It appears lightweight, collapsible, and quick and easy to install,” said competition judge Dr. Benedyk.

Third Place $1,000.00 Scholarship: LOFT

Kristoffer Steen Langvik from The Oslo School of Architecture and Design in Oslo, Norway created Loft, lifting equipment for use in sea rescues.

The Loft rescue equipment “aims to use the high strength and corrosion resistant properties of aluminum to provide a tool for people in dangerous situations. It requires minimal post processing and is made up of two different profiles, making it an economical and practical solution to [sea] rescue, ” said Langvik.

The Loft rescue equipment “aims to use the high strength and corrosion resistant properties of aluminum to provide a tool for people in dangerous situations. It requires minimal post processing and is made up of two different profiles, making it an economical and practical solution to [sea] rescue, ” said Langvik.

Langvik’s main motivation for Loft was the difficulties faced when rescuing refugee children in the ocean. “Refugees traveling at sea, as well as the people volunteering to save them, are faced with huge dangers,” he said. “Equipment that is lightweight, robust, and versatile may help in these difficult situations.”

The judges were impressed with the creative use of extrusions and choice of alloy in the Loft, “The 5052 (2.5% Mg) alloy is extrudable and is one of the non-heat treatable alloys offered in extruded form. It’s especially for marine applications due to its superior corrosion resistance relative to 6xxx alloys,” said Dr. Benedyk.

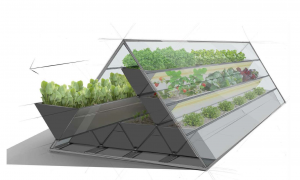

Bonnell Sustainable Design Challenge $2,500.00 Scholarship: Space-Saving Greenhouse

The Sustainable Design scholarship is awarded to the student who best displays an understanding of utilizing aluminum extrusions that are viable, environmentally-friendly and contribute to people’s quality of life.

Johanna Sofie Brämersson of The Oslo School of Architecture & Design in Oslo, Norway is this year’s winner. Her Space-Saving Greenhouse “makes it simple for people to get together and grow [plants] in small spaces like rooftops and courtyards,” said Brämersson.

Johanna Sofie Brämersson of The Oslo School of Architecture & Design in Oslo, Norway is this year’s winner. Her Space-Saving Greenhouse “makes it simple for people to get together and grow [plants] in small spaces like rooftops and courtyards,” said Brämersson.

The Space-Saving Greenhouse design allows space for growing optimization. Compost containers and aluminum profile rails for LED light strips help improve efficiency of the growing system. The pyramid shaped green house uses extrusions throughout its design. The pull out triangular soil beds slide on extruded aluminum tracks.

“The 6063 aluminum alloy gives provides high resistance against all kinds of weather and doesn’t corrode much, which gives it a long service life and a low environmental impact,” Brämersson said. The greenhouse is built to withstand all season’s temperatures including extreme cold. Insulation can be attached to the extruded aluminum mounts on the inner walls of the greenhouse.

Honorable Mention: Tool-Changing Pen Plotter

Joshua Vasquez received honorable mention for his use of extrusions and open design of the Tool-Changing Pen Plotter.

“The Tool-changing Pen Plotter is my answer for a future world where 3D printers transform into multipurpose motion platforms, ”said Vasquez. “It is intended as a reference design for machine builders eager to create multipurpose machines with many heads.”

Vasquez published his design to be available for any creator to use for their own designs and machines. Competition judges recognized Vasquez’s willingness to eagerly and earnestly share his work. “Although the design he built uses basic extruded shapes for a platform, that’s the point of this machine – to use materials that are readily available in order for anyone to build their own version,” said Asher.