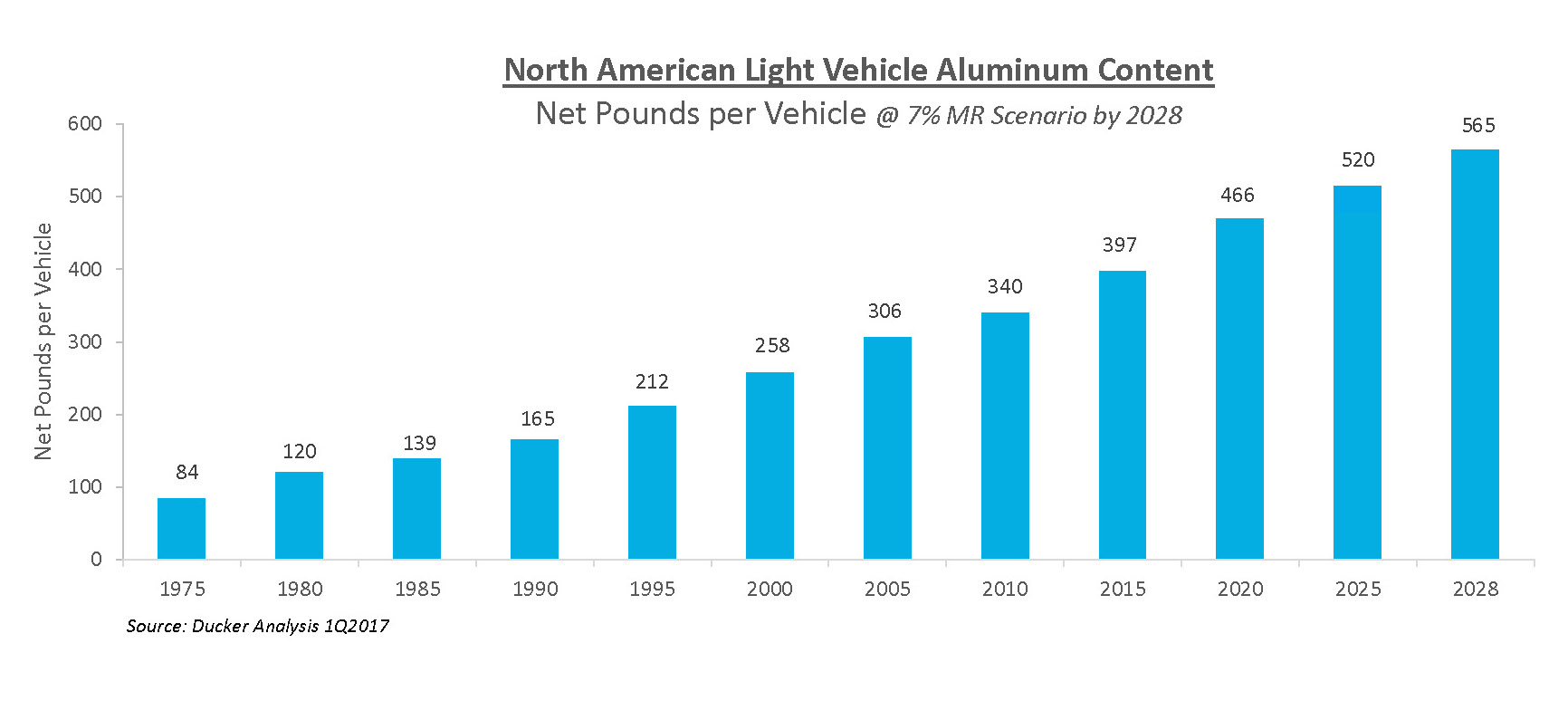

Over the next decade, automakers will continue to increase the adoption of high-strength, low weight aluminum in new car and truck construction at a faster pace than any time in history. Total aluminum content is expected to grow from 397 pounds per vehicle (PPV) in 2015 to 565 PPV by 2028, representing 16% of total vehicle weight, according to a survey of automakers conducted by Ducker Worldwide, reaffirming continued market share growth for aluminum into high-volume vehicles. This is consistent with the emerging trend of automakers transitioning to a multi-material vehicle (MMV) design approach, choosing aluminum for doors, hoods and trunk lids, body-in-white, bumpers, and crash boxes.

“Aluminum remains the fastest growing automotive material over competing materials and is entering its most unprecedented growth phase since we’ve been tracking the shifting mix of automotive materials,” said Abey Abraham of Ducker Worldwide. “To further improve fuel economy, battery range, safety, and overall driving performance, automakers no longer default to a single material and instead are pursuing a multi-material design approach where the best material is chosen for the best application. This design evolution is what’s driving aluminum’s increased market penetration in the auto sector.”

“As our automotive customers embrace a multi-material approach to new car and truck design, that directly translates to increased amounts of aluminum. On top of 40 years of uninterrupted growth, the aluminum industry is experiencing a level of sustained growth not seen before in any market or product sector. However, the true winners of this change are American consumers who can choose next-generation cars and trucks that are high performing, efficient, safe, sustainable and more fun to drive,” said Heidi Brock, president and CEO of the Aluminum Association. “A thriving aluminum sector is vital to automakers, the nation’s manufacturing base and a healthy U.S. economy. The aluminum industry invested or committed more than $2 billion to ensure increased capacity in the U.S. since 2013, and the industry is prepared to continue such investments in domestic manufacturing jobs as demand continues to grow.”

2020 Projections

The study finds that total aluminum content for North American lightweight vehicles will increase to nearly 9 billion lbs, averaging 466 PPV by 2020, an increase of 69 lbs from 2015. Aluminum parts will more than double with aluminum hoods expected to reach 71% penetration (up from 50% today). Fifty percent of total aluminum content growth from 2015 to 2020 will be driven by closures, crash management systems, steering knuckles, and structural vacuum die cast parts. Aluminum vacuum die castings are expected to grow from less than three PPV today to 14 PPV by 2020. The average passenger car will contain 362 lbs of aluminum and the average light truck will contain 523 lbs of aluminum by 2020.

2020 to 2028

Ducker projects total aluminum content growing to 565 PPV (16% of curb mass) by 2028 with nearly 25% of vehicles having a partial aluminum body-in-white. More than two million of those vehicles will be pickup trucks and 400,000 will have plug-in hybrid or zero-emission powertrains. Forecasts for the 2020 to 2028 time period are based on EPA and NHTSA technology implementation pathways suggesting mass reduction from zero percent for some passenger cars and small SUVs to 20% for large trucks and SUVs to achieve an overall industry average mass reduction of 7% (270 lbs) by 2025. Empirical evidence from Ducker’s research suggests achieving 7% curb mass reductions is likely to be delayed to 2028 due, in part, to new model launch timing constraints with several vehicles expected to launch post-2024 with significant aluminum body content. Under either scenario, a multi-material approach is the expected pathway with aluminum contributing to more than 50% of total mass reduction.

Brock added, “It is proven that vehicles made lighter with aluminum offer consumers better fuel economy, improved safety and enhanced performance. Furthermore, aluminum is the best choice for the environment when compared to both traditional and advanced steels, according to the U.S. Department of Energy’s Oakridge National Laboratory.”

Methodology

The new Aluminum Content in North American Light Vehicles 2016 To 2028 study — commissioned by the Aluminum Association’s Aluminum Transportation Group (ATG) and conducted by Ducker Worldwide — is based on a top down analysis relying primarily on detailed in-person interviews with automotive OEMs and their suppliers, as well as data obtained from the U.S. Environmental Protection Agency, National Highway Traffic Safety Administration, and the Center for Automotive Research. With its top down analysis, Ducker Worldwide determined mass reduction and material mix forecasts and examined the effect of fuel prices, vehicle mix, secondary weight savings, electrification, vehicle design, and vehicle launch cadence on the amount of weight that is expected to be shed by vehicle type. The full study can be viewed online.