Novelis will be supplying Nissan with sustainable, lightweight aluminum body sheet for the new Qashqai SUV. A best-selling SUV in the C-segment, the Qashqai will incorporate aluminum in the hood, doors, and front fenders to reduce weight and increase fuel efficiency. The aluminum in the new SUV has helped it achieve a total of 60 kg of body-in-white weight savings compared to the previous model. This is just one example of the growing trend by major automakers to increase aluminum use in smaller vehicle segments and high volume production models.

Through Novelis’ global Customer Solution Center network, engineers have proven to automakers that lightweighting with aluminum doors and hoods are a cost-effective way to reduce weight. The all-new Qashqai will be Nissan’s first model built in Europe using a significant number of lightweight aluminum panels.

“We are delighted to provide Nissan with sustainable aluminum body sheet solutions as they continue to design lighter, more fuel-efficient vehicles with reduced life-cycle emissions,” said Michael Hahne, vp Automotive, Novelis Europe. “Novelis is uniquely positioned to meet the increasing demand for automotive aluminum given its unmatched global footprint and ability to develop innovative, sustainable solutions. We look forward to working with Nissan as they continue to adopt more aluminum and increase their recycling capabilities.”

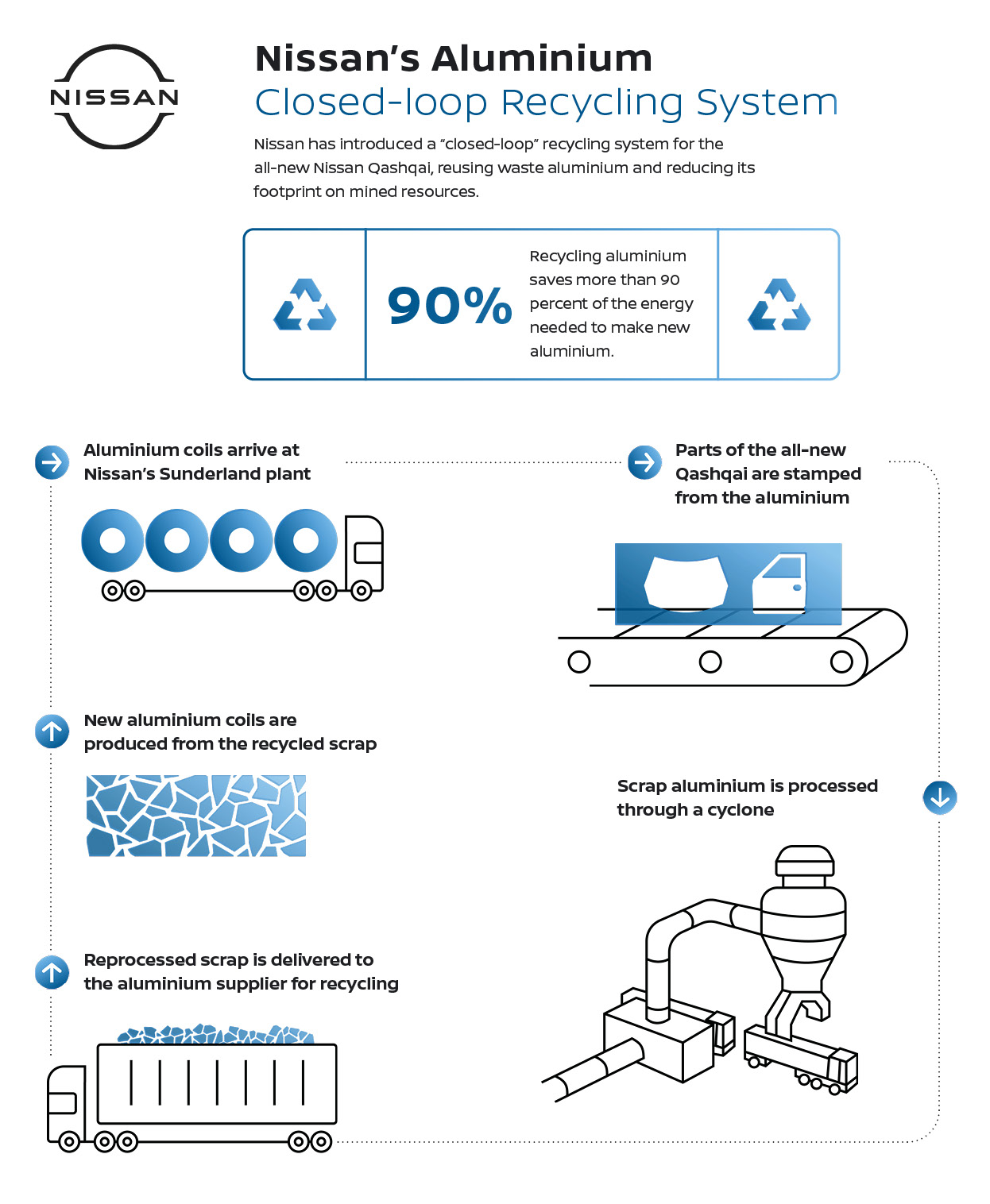

Establishing a Closed-Loop Aluminum Recycling System

The collaboration on the Qahqai became an impetus for both companies to achieve a more sustainable manufacturing process by jointly establishing a closed-loop recycling system. Novelis will deliver aluminum material from its plant in Nachterstedt, Germany, to Nissan’s car plant in Sunderland, U.K., where it will then collect the manufacturing scrap. Teh automaker will return the scrap to Novelis recycling centers in Europe to be cast and rolled again for production by Nissan. This process creates a circular supply chain that helps both companies achieve their sustainability goals.

Aluminum production at Nissan’s Sunderland plant includes a second extra large press line, which was launched last year and the cyclone — a recycling facility that blasts out scrap metal at 150 km an hour and can handle more than seven tons of metal an hour, ensuring less waste and a greener production process. As hoods and doors are stamped into shape, scrap material is shredded and extracted, keeping aluminum grades separate. The separation ensures that the automaker can return high-quality scrap to Novelis who can turn the scrap into aluminum alloy sheets once again.

The new Qashqai follows the new Rogue sold in North America as the second global model for Nissan to feature aluminum parts produced with the closed-loop recycling process. The automaker is considering expanding the application of this process to future models and other factories.