Every Lotus model benefits from the company’s approach to engineering in lightness at every stage of design and construction. Leading the field in advanced construction techniques and technology, Lotus has continuously strived to push boundaries. The company has contributed to the evolution of automotive design with many innovations, including the GRP monocoque in the Lotus Elite and the bonded aluminium chassis in the Elise. Lotus was also the first company to introduce a Formula 1 car constructed from carbon fibre.

Today, Lotus cars are developed through the company’s Lightweight Laboratory concept. This philosophy has grown to provide a framework for evaluating every component. Viewing components in isolation, as well as part of a sub-assembly and even the car as a whole, allows each component to be assessed, optimized, and re-engineered.

Through this approach, the company has slashed a substantial 207 kg from its cars this year alone, with its heaviest model weighing in at just 1,395 kg.

Light Is Right

With a heritage of efficient design that stretches back to 1948, Lotus remains true to the ethos of the company’s founder Colin Chapman, and his approach to design and construction, which included the tenant that light weight is essential to speed performance. “We’re not concerned with following other car manufacturers,” said Jean-Marc Gales, CEO of Group Lotus plc. “Innovation comes from taking a new approach, and we don’t stop looking. Colin Chapman famously said, ‘Adding power makes you faster on the straights, subtracting weight makes you faster everywhere,’ and that thinking has become part of our DNA. To perfect a pure sports car, you must consider weight your enemy. Lose weight and you will make significant gains: harder and faster cornering, better braking, greater agility, and responsiveness, along with faster acceleration.”

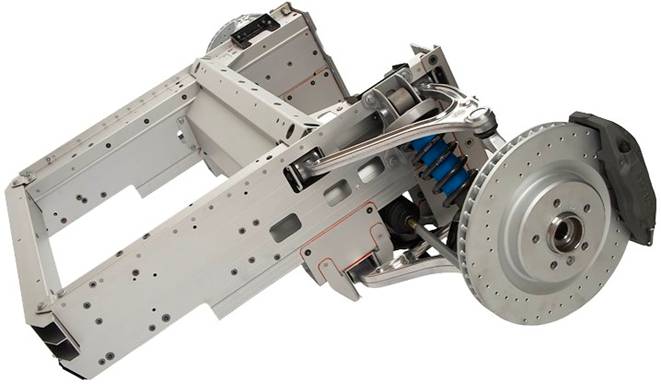

Looking at a car holistically allows for all redundant weight to be removed, with every part serving a purpose. Far more than just boosting straight-line performance, reducing a car’s kerb weight allows for the correct calibration of the suspension. This allows sharper handling and better body and roll control, but not at the expense of ride comfort and composure. The overall reduction of weight also allows for optimized weight distribution, a huge contributor to the poise and balance of a sports car during high-speed cornering.

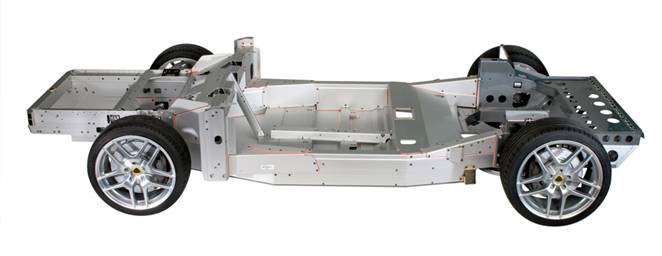

Proving this principle, Lotus’ aluminium vehicle chassis technology is still considered a benchmark within the automotive industry. Utilizing strong and stiff extruded and bonded aluminium sections the simplicity off the tub construction belies its benefits. Able to employ lightweight extrusions, joined by epoxy adhesive, it’s immensely strong and torsionally stiff, yet the chassis for the Elise and the Exige tips the scales at just 68 kgs. Not only is this roughly half the weight of an equivalent steel chassis, it’s also substantially simpler to produce than a similar weight carbon fibre alternative and easier to adapt to the requirements of specific models.

As an antidote to sterilized and attenuated modern cars, Lotus’s approach continues to deliver a pure, undiluted driving experience. Avoiding systems that rob cars of their fun factor, including electric power steering, it places function over convenience, to produce truly involving vehicles. Its latest models continue the Lotus approach to light is right engineering.