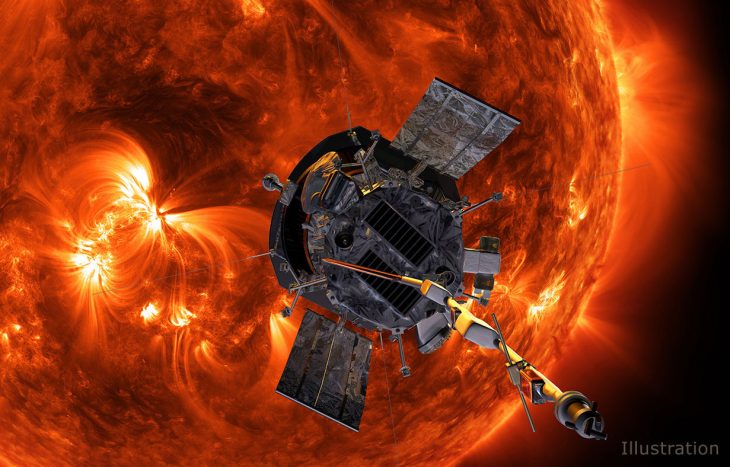

The Parker Solar Probe, launched on August 12, 2018, began a journey that will bring it closer to the sun than any mission before. The probe carries sensors and instruments that will enable unprecedented, close-up observations of the Sun’s corona and solar wind, which will address unsolved scientific questions, as well as making contributions to our ability to forecast major space weather events that have an impact on life and technology on Earth. In order to make this journey possible, a mix of materials — including titanium, aluminum, and composites — have been used in the construction of the spacecraft, keeping the craft cool and lightweight.

Keeping Cool

Journeying as close as 3.8 million miles (6.2 million km) to the Sun, the Parker Solar Probe had to be designed in order to withstand intense temperatures, while keeping the interior at about 85°F. To protect the craft, it is outfitted with a Thermal Protection System (TPS), which includes a 4.5 inch thick (11.43 cm) carbon-composite shield treated with a highly reflective aluminum oxide coating that can protect the instruments at temperatures of nearly 2,500°F. The TPS is supported by a milled titanium structure built by Tricor Metals.

However, not all of the instruments will be behind the TPS, such as the Solar Probe Cup—a sensor designed to measure ion and electron fluxes and flow angles from the solar wind. In order for the instrument to survive the heat and still be able to return data to Earth, the cup is made from titanium-zirconium-molybdenum alloy sheets with an inherent high melting temperature.

Also not protected by the TPS are a series of solar panels that provide power to the instruments and systems of the craft. The panels are outfitted with a cooling system that includes two titanium radiators, aluminum fins to maximize the cooling surface, and pumps to circulate the deionized water coolant.

Launch Vehicle

Light metals also supported the Parker Solar Probe during launch, which was performed using a three-stage rocket, called the United Launch Alliance Delta IV. The boosters are constructed of isogrid aluminum alloy barrels, sun-formed aluminum domes, and aluminum tank skirts—all which enable the rocket to be structurally rigid. In addition, the Delta cryogenic second stage propellant tanks are made from isogrid aluminum ring forgings and spun-formed aluminum domes.

As of October 31st, the Parker Solar Probe has begun its first of 24 solar encounters. Its instruments are operating and it has begun collecting and delivering data back to NASA scientists.

Editor’s Note: A version of this article first appeared in the December 2018 issue of Light Metal Age. To receive the current issue, please subscribe.