The Aluminum Association just released the 2018 Molten Metal Incident Report covering calendar year 2017. The report also summarizes historical data for the years 1980 through 2016. It highlights the predominant hazards that result in explosions during molten aluminum management worldwide, incorporating roughly 300 aluminum plants in 20 countries. Though not a statistical representation of the industry due to the fact that incidents are voluntarily reported, this tracking nonetheless is an important marker to highlight the hazards in working with molten aluminum and inspire a greater awareness of safety in the workplace.

Incidents and Injuries

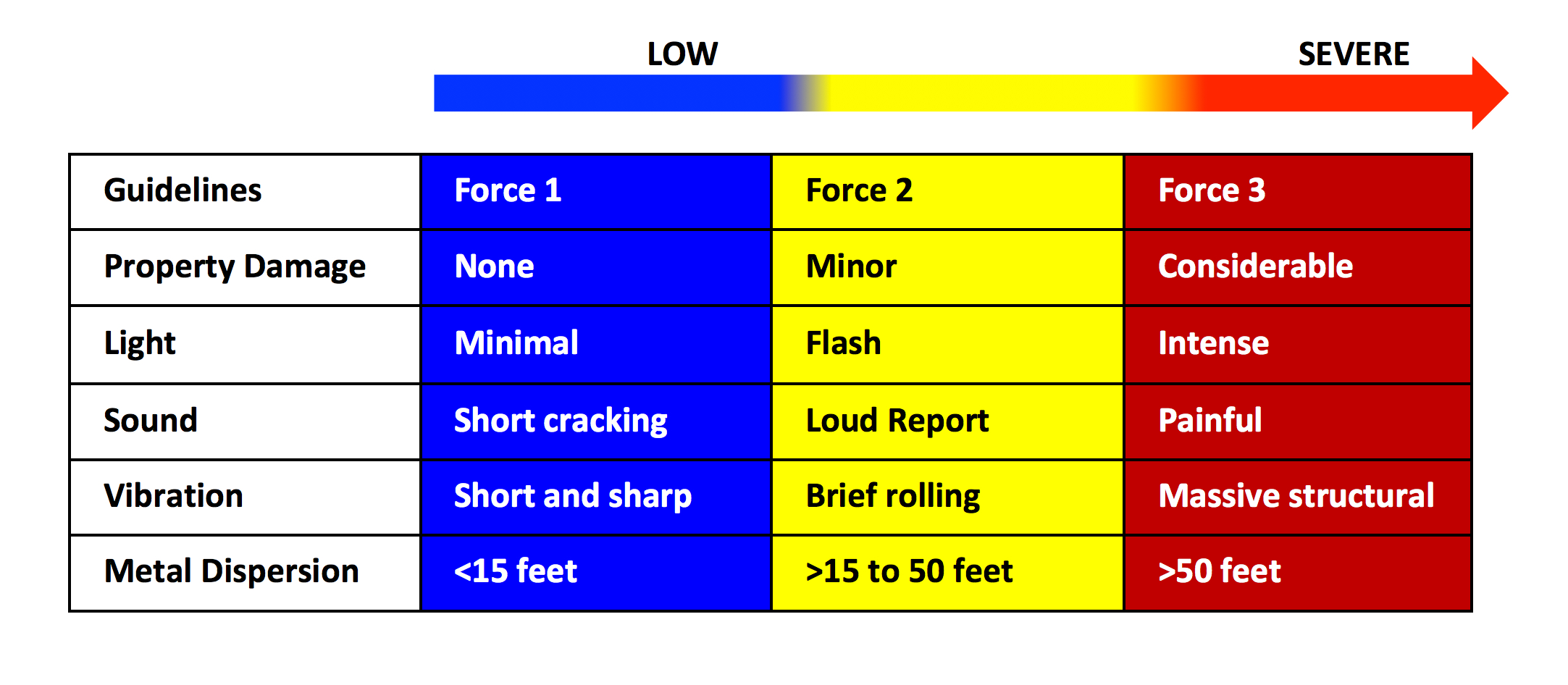

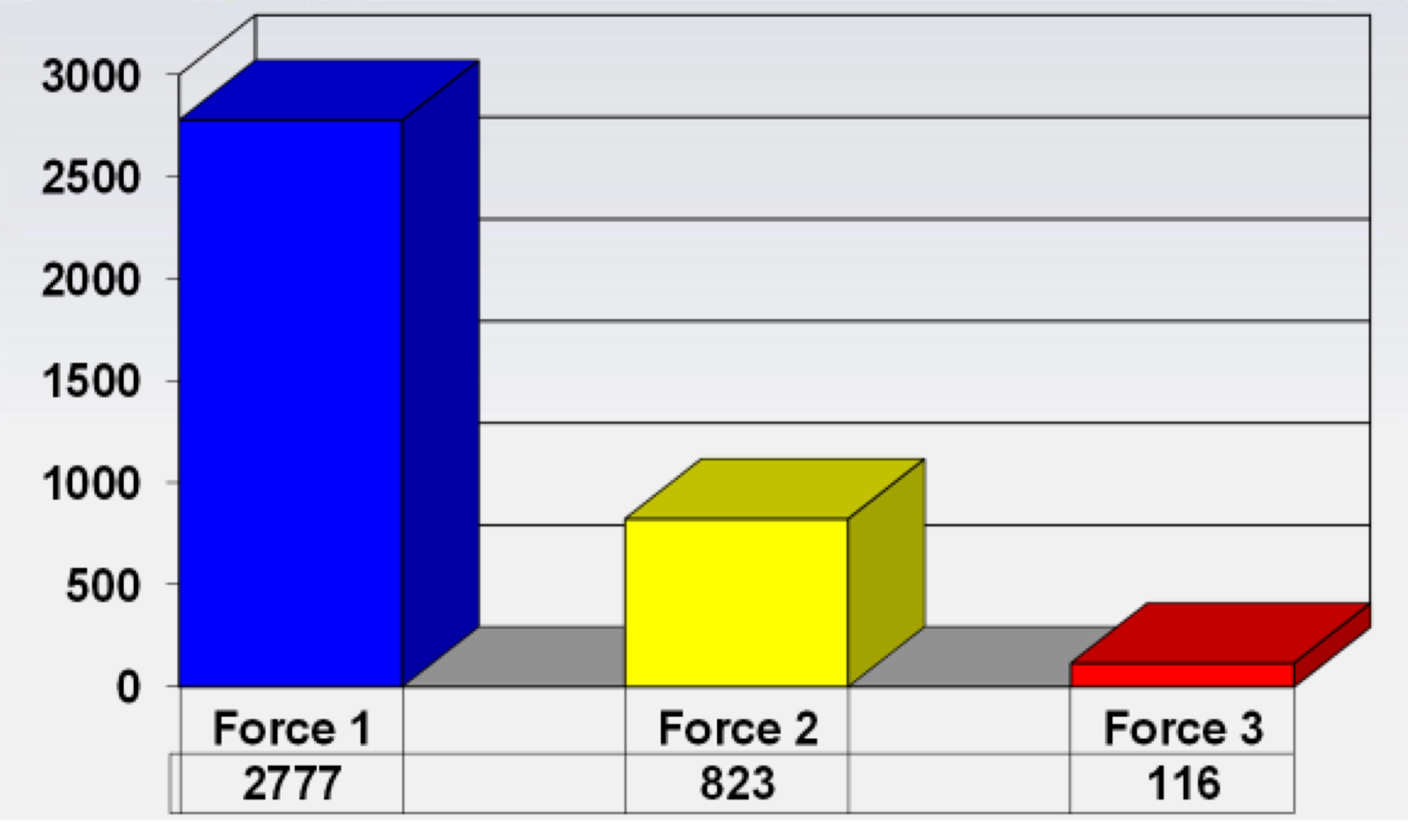

The trend for explosion incident reports was down slightly, with 181 in 2017, compared to 195 reports in 2016. However, 181 explosions is still the second highest number of incidents ever reported. Fortunately, there were only eight minor injuries reported and no serious injuries or fatalities. This is the lowest number of injuries ever reported since the Aluminum Association started collecting incident data in 1980. There were 157 Force 1 explosions, 24 Force 2, and zero Force 3 explosions reported in 2017. The differences in explosion force levels, from least to most severe, is shown in Figure 1. A total of 3,716 incidents were reported from 1981 through 2017 (Figure 2).

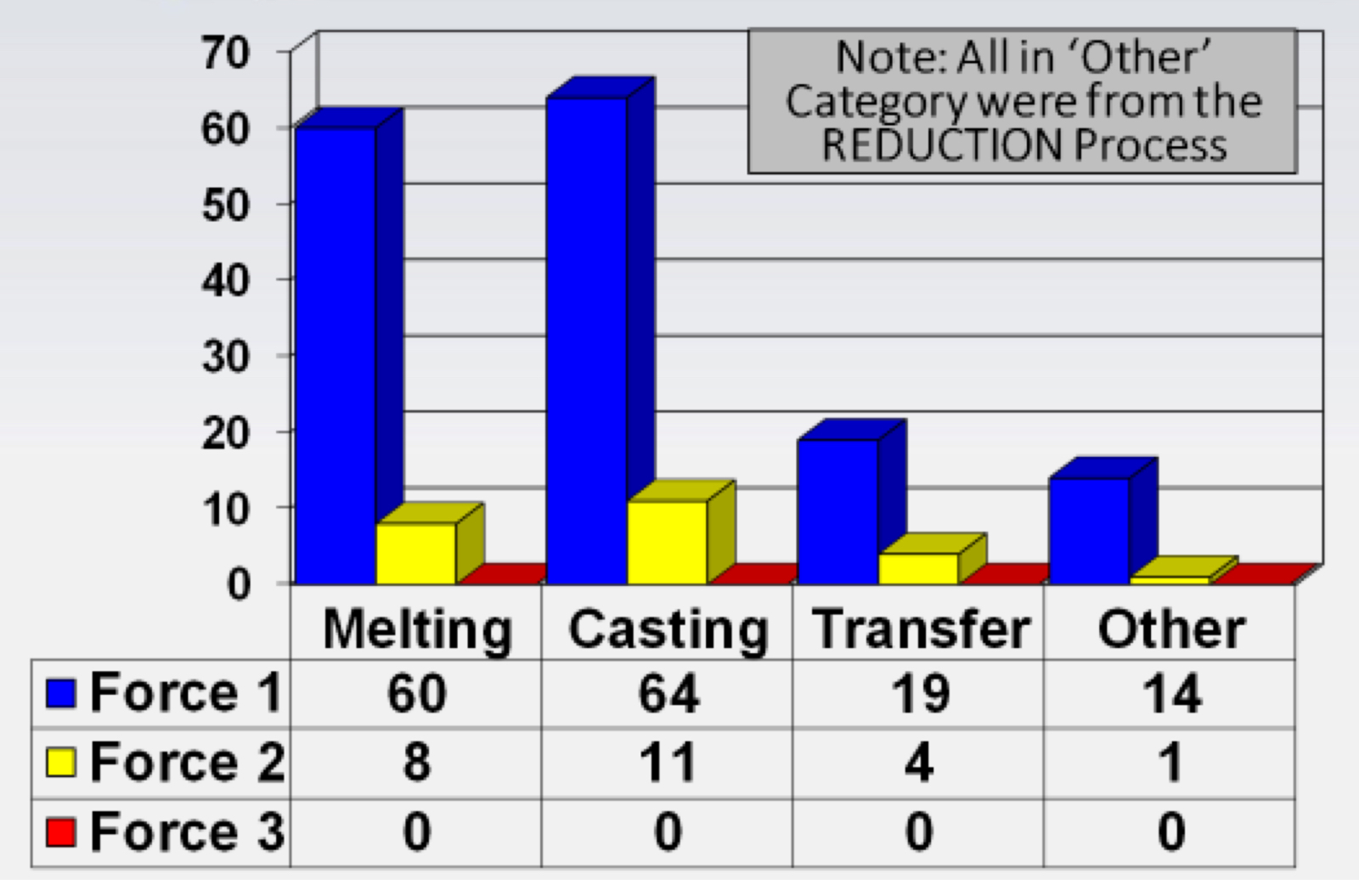

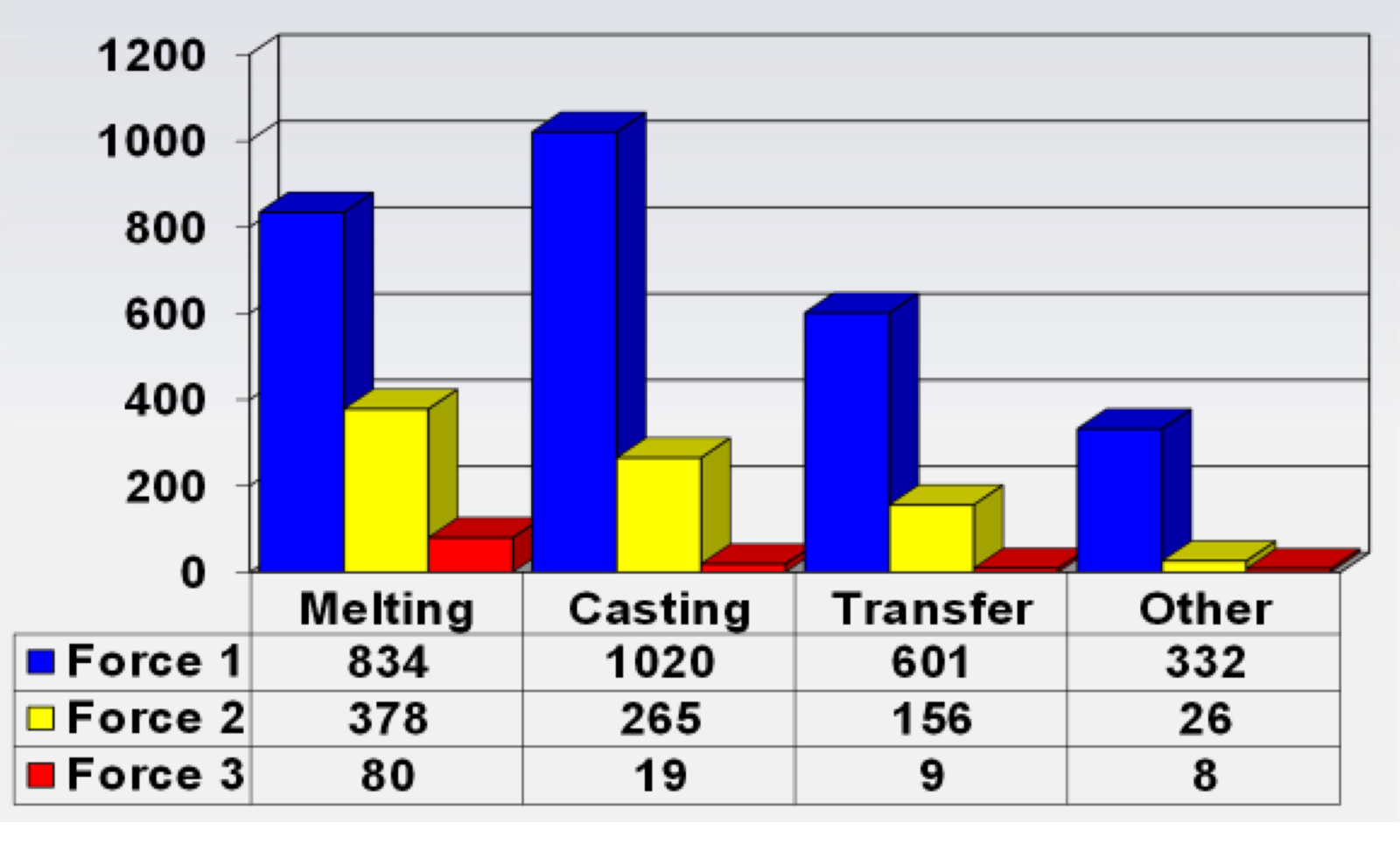

Incidents by Industry Operation: The 2017 force level data for each of the four major categories of operations: Melting, Casting, Transfer, and Other is shown in Figure 3. Most incidents occurred in Casting (75) compared to Melting (68), Transfer (23), and Other (15). As is typical of past years, by far the highest portion of casting incidents in 2017 occurred at the start of the cast (90%). The historic trend of more Melting incidents has been reversed in recent years with more Casting explosions reported. Currently, the total number of Casting and Melting incidents is about equal for the entire reporting period beginning in the 1980s. However Melting continues to be responsible for most of the higher force level incidents (Figure 4).

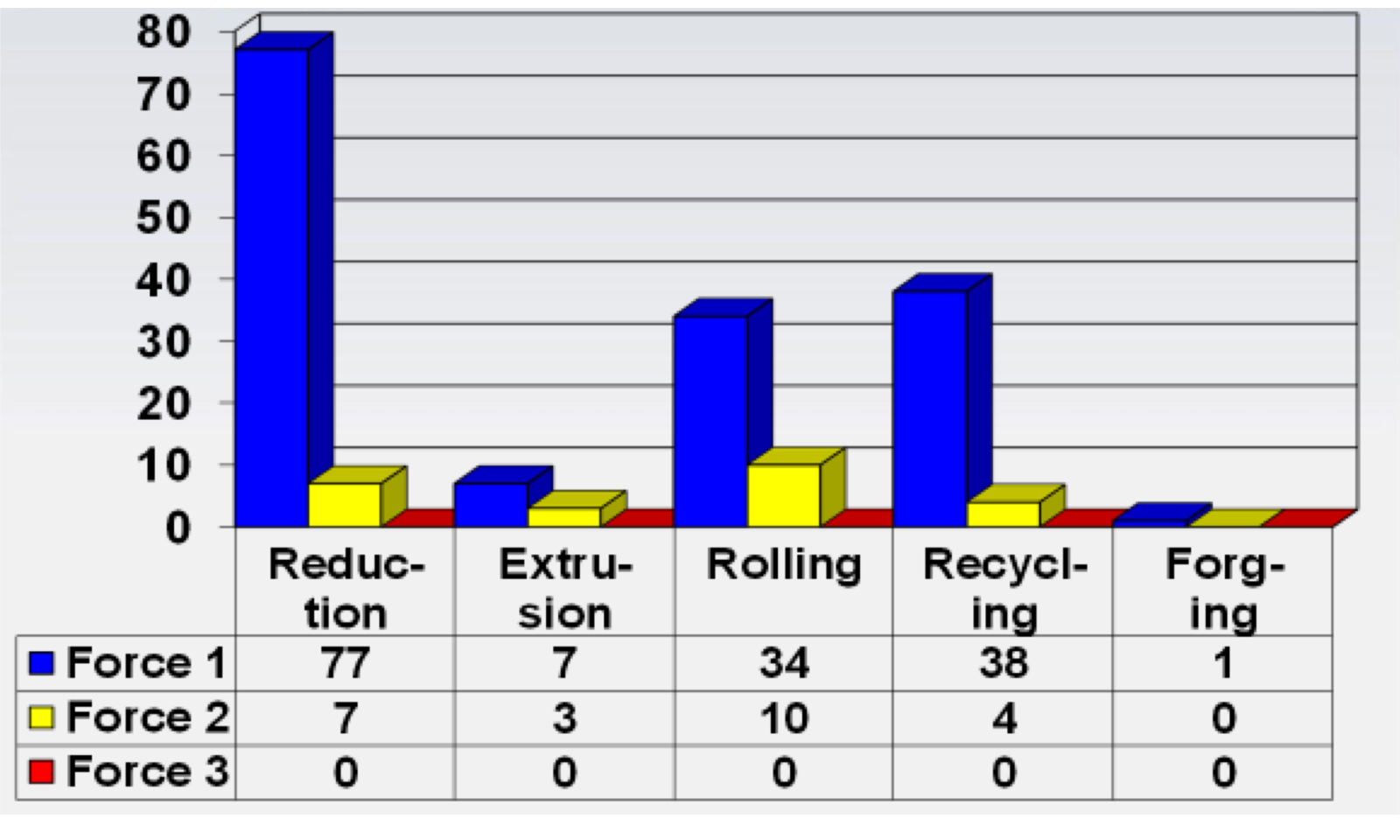

Incidents by Process Plant: In 2017, almost half (84 of 181 explosion incidents) were reported by Reduction facilities. Rolling and Recycling had similar numbers with 44 and 42, respectively. Rolling had the highest number of Force 2 incidents (10), while Reduction was next highest with seven (Figure 5).

Making Industry Safety a Priority

The Aluminum Association has made the safety and well being of the industry’s employees a top priority. The association believes the reported incidents can be minimized or eliminated entirely by careful attention to safe material handling practices and the sharing of best practices. To that end, their safety programs include: the development and distribution of publication on the safe production and handling of aluminum, Casthouse Safety Workshops to educate plant workers and managers on workplace safety, and ongoing testing and reporting with member companies for continued safety improvements

Editor’s Note: A copy of the 2018 Molten Metal Incident Report as well as the Molten Metal Incident Reporting form is available by download at: www.aluminum.org/resources/electrical-faqs-and-handbooks/safety and completed incident reports can be submitted to cwells@aluminum.org.

This article first appeared in the December 2018 issue of Light Metal Age. To receive the current issue, please subscribe.