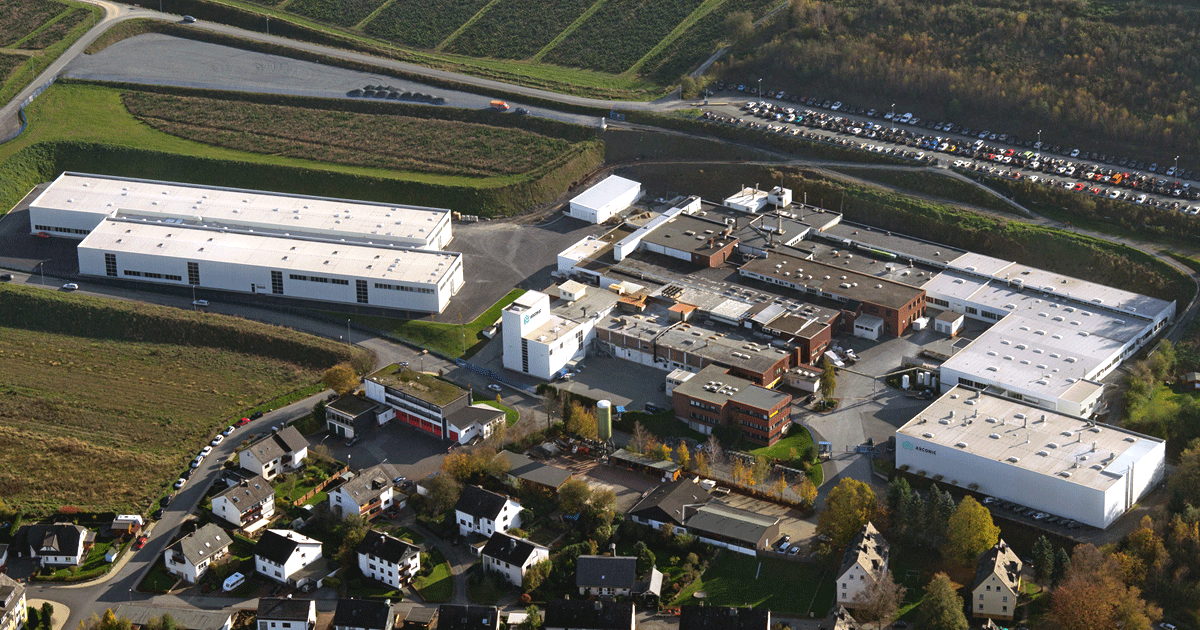

Arconic officially opened its expanded aluminium and titanium aerospace parts facility in Bestwig, Germany. The expansion increases Arconic’s production capacity to meet growing demand from commercial aircraft customers for lightweight titanium investment castings for the aerospace industry.

“We have significantly invested in Arconic Bestwig’s capabilities, almost doubling our titanium

parts production capacity, and have added state-of-the-art manufacturing equipment as part of

our efforts to better serve our customers,” said Jeremy Halford, president of Arconic Engineered

Structures. “Combined with our previous investments in Bestwig, this latest expansion is

providing additional capacity to deliver even more of the titanium components our customers

need to build aircraft at high volumes.”

The expansion includes advanced manufacturing equipment for more efficient production and enables increased production of large titanium structural castings up to 1.5 meters in diameter for leading commercial aircraft platforms. The expansion has created approximately 70 new jobs.

Additional Investments

Arconic has been investing in increased capacity to capture growth in the global aerospace market and support customers’ historic aerospace ramp. It recently launched expansions totaling more than $100 million to increase aero engine parts production in Whitehall, Michigan and Morristown, Tennessee in order to provide additional capacity to meet growing demand from aerospace engine customers. The expansions are expected to be operational by the end of 2020.

In addition, the company has installed advanced aerospace plate manufacturing capabilities in Davenport, Iowa. This includes a new horizontal heat treat furnace and a thick plate stretcher, which are aimed at meeting the demand for thick aluminum plate, particularly for composite wings made from monolithic thick plate wing ribs.