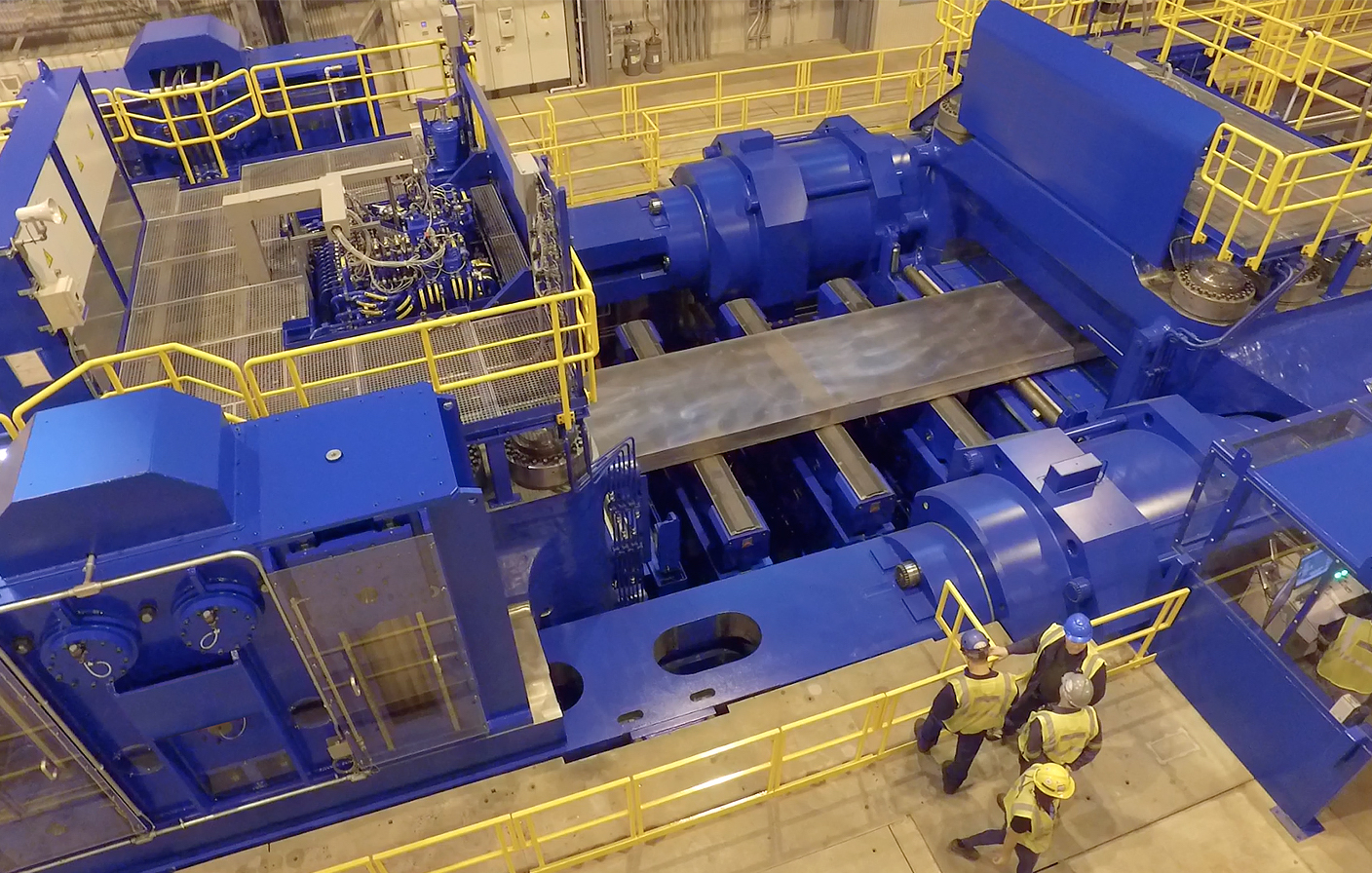

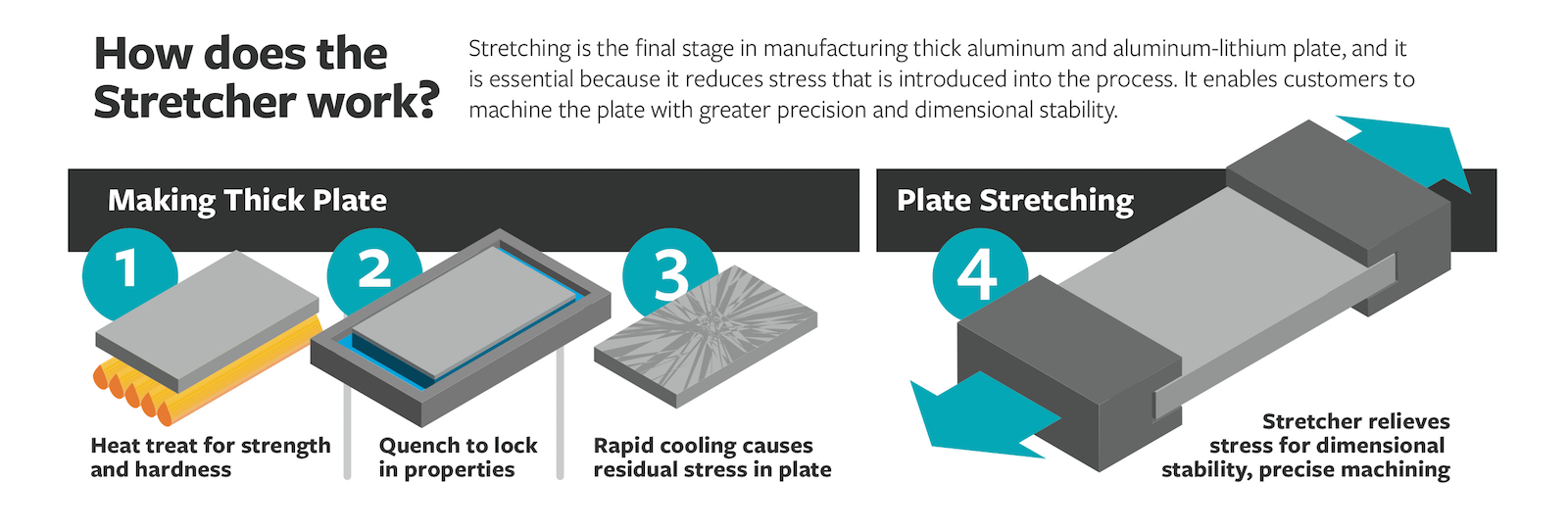

Arconic completed the installation of its new manufacturing technology — the Very Thick Plate Stretcher. Located at the company’s facility in Davenport, Iowa, the stretcher improves the performance of thick aluminum and aluminum-lithium plate in aerospace and industrial applications. The stretching process reduces stress introduced into the plate as part of the manufacturing process, resulting in a part that is more easily machined and processed by customers.

(Image: Arconic.)

In aerospace, the stretcher will not only enable Arconic to service the existing plate market, but also allow airframe builders to make large wing ribs, fuselage frames, and bulkheads in new sizes and thickness. For example, one of the challenges composite wings face as they get larger is strength and stiffness, and the aluminum plate from this stretcher will allow aircraft manufacturers to make aluminum wing ribs to address that issue. In the industrial market, plate from the stretcher can be used in manufacturing molds and chambers for applications such as semiconductors.

According to the company, the stretcher is said to have achieved multiple world records. It is the longest and widest stretcher in the world, able to stretch plates over 26 yards long and 14 feet wide. It can also stretch the thickest and heaviest plate in the world, processing pieces over 12 inches thick and over 40,000 lbs, as well as being able to achieve the greatest stretcher pull force ever used at 35 million lbs — equal to 550 modern locomotives.

Arconic believe the investment will expand its leadership in the aerospace market and create profitable growth in attractive industrial markets. The company stated, “The stretcher allows Arconic to offer a variety of new products: in aerospace, we can now help aircraft engineers push the boundaries of design and performance. In other industrial applications, such as semiconductors and consumer electronics, Stretcher material helps increase productivity and reduce cost. In both cases, Arconic will help create demand that we are uniquely positioned to meet. And making all of this possible is our team in Davenport, who delivered this massive project on time and $40 million under budget.”

The $150 million project was completed on time and is supported by customer contracts, including one with Airbus, valued at approximately $1 billion. Arconic’s Davenport facility is currently commissioning the Stretcher, and has begun qualifying material for its customers.