Additive manufacturing is becoming increasingly important, with cheaper and more efficient processes making the production of metal powders and additively manufactured components more attractive. As a result, printed components are increasingly being used not only for prototyping, but also as serial products.

Trimet Aluminium SE in Germany has been conducting intensive research and development on material and processing requirements for additive manufacturing, building up a broad knowledge base in the area of powder production and 3D printing technology. The fruits of that research have been realized with the introduction of a new aluminum alloy for additive manufacturing, specifically for the selective laser melting (SLM) process

The Manufacturing Process

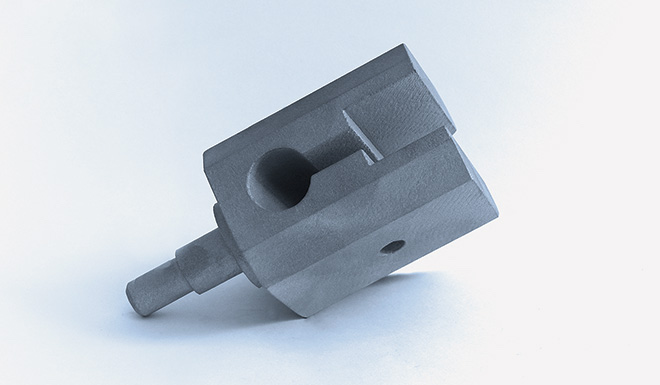

Aluminum alloy powders are often produced by atomizing aluminum ingots. The aluminum powder is then transferred to an additive manufacturing machine. In the case of the SLM process, a layer of aluminum powder is formed on the bed of the machine. Laser radiation melts select areas of the powder and solidifies, forming a layer of metal. The powder is spread over the surface area again, at which time the laser forms another layer of material. This cycle of building layers of material is repeated until the component is completed.

In contrast to conventional shape casting processes, SLM does not require any specific molds or tools, which can be costly. A further advantage is the high degree of design freedom, enabling complex geometrical shapes that cannot be achieved through conventional shape casting. For example, weight-optimized components with bionic structures can be produced comparatively inexpensively.

The New Alloy

Based on Trimet’s trimal®-05 alloy, the new aluminum alloy trimal®-05AM was developed specially for the production of high strength, lightweight parts using the SLM process without the need for additional heat treatment. The company believes that this new alloy will enable the expansion of additive manufacturing, particularly in the transport sector with its high demand for aluminum materials.

“With the new alloy, we are expanding the application areas for aluminum,” says Thomas Reuther, member of the executive board of Trimet Aluminum SE. “The transport sector alone increasingly relies on additive manufacturing, thereby raising the demand for materials that have been developed for this process.”

Trimet conducted comprehensive testing on the new alloy as part of a research project in cooperation with the Leibniz Institute for Material Engineering in Bremen, Germany. The project provided evidence of the alloy’s suitability for SLM additive manufacturing.

In addition to powder characteristics and layer thickness, SLM process parameters were also investigated. For example, the distance between parallel melt paths and the speed of the laser beam have a decisive influence on the component properties. To determine the mechanical properties, tensile tests were carried out before and after classic T6 heat treatment, a process that is also used for processes such as gravity die castings. The study found that after classic T6 heat treatment, the mechanical properties are comparable to those of cast components — making trimal®-05AM suitable for both prototype production and select serial products.