Norsk Titanium AS received an order for 3D-printed titanium structural components from Boeing. The parts, which are being produced by the company’s proprietary Rapid Plasma Deposition (RPD™) process, are the first 3D-printed structural airplane components to to be approved by the FAA. It has been reported that the use of these 3D-printed components could eventually save Boeing up to $3 million in construction costs on each jet built.

“We are proud to take this historical step with a great aerospace innovator like Boeing,” said Warren M. Boley, Jr., Norsk Titanium’s president and CEO. “The Norsk Titanium team will continue to expand the portfolio of components supplied to Boeing meeting stringent certification requirements. It is an honor to earn FAA approval for these structural parts.”

Boeing designed the components and collaborated closely with Norsk Titanium throughout the development process. To certify these initial structural components on the Dreamliner, the companies undertook a rigorous testing program with FAA certification deliverables completed in February 2017. Norsk Titanium, with their wire-based RPD process, is the first supplier to achieve Boeing’s high deposition rate material specification.

“From the outset, the 787 has been the hallmark of innovation and efficiency,” said John Byrne, vice president, Airplane Materials and Structures, Supplier Management at Boeing Commercial Airplanes. “We are always looking at the latest technologies to drive cost reduction, performance, and value to our customers and Norsk Titanium’s RPD capability fits the bill in a new and creative way.”

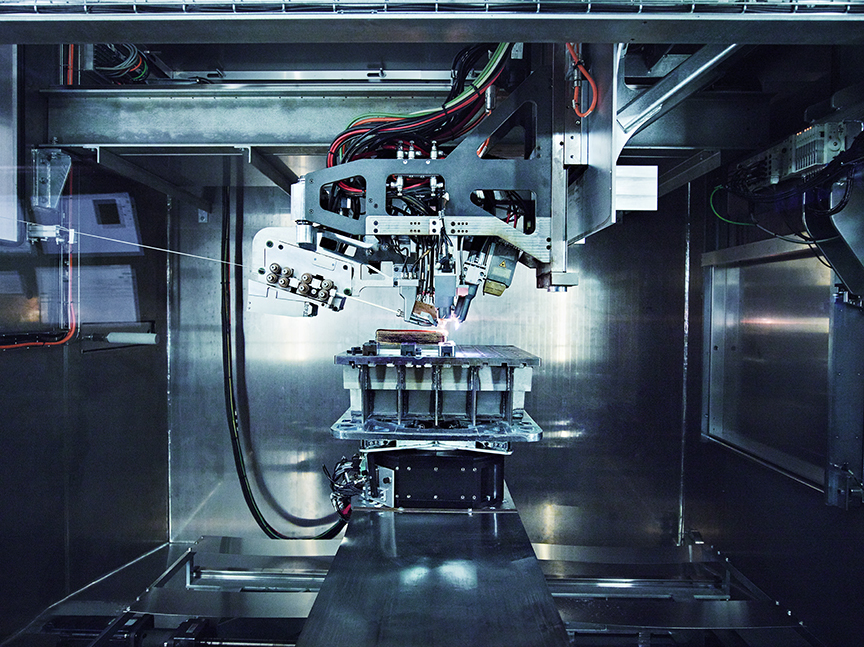

Norsk Titanium’s patented MERKE IV™ RPD machine is said to produce titanium components that can cost 50-75% less than other equivalent components. The novel RPD process feeds titanium wire into a set of plasma torches protected by a cool argon-gas environment and precisely and rapidly built up layers to a near-net-shape (up to 80% complete) that requires very little finish machining. According to the company this process has made it possible to replace massive forged parts — which take months and even years to develop and produce — with precision, additive manufactured components. The company constructed the first industrial-scale aerospace additive manufacturing plant in Plattsburgh, New York, in partnership with SUNY Polytechnic Institute.