Kubikenborg Aluminium AB (KUBAL), Sweden’s only primary aluminum producer, is taking a transformative step toward sustainable and circular production with the planned installation of a new remelting plant (Figure 1). Supported by the Swedish Energy Agency, the new facility will enable the company to recycle aluminum scrap, lower its energy consumption, and improve the flexibility of its production process. Through this investment, KUBAL aims to recycle up to 90% of aluminum used in production, making its products more attractive to new and existing customers.

“We are making an important step toward the future,” said Mats Andersson (pictured), CEO of KUBAL. “Our new remelt plant will allow us to utilize state-of-the-art equipment in order to achieve our targets in recycling and sustainability and to deliver to our customers the metal with one of the lowest CO2 footprints in the world.”

Company Profile

KUBAL started up its aluminum smelter during World War II, with the first aluminum ingot cast on November 9, 1942, a historic milestone for the Swedish industry. The raw materials for the smelter came from Skellefteå and Gotland, making the entire process fully domestic.

After its launch, the smelter faced waves of ups and downs. “In the following decades, KUBAL expanded several times as aluminum became known as ‘the metal of the new age.’ However, environmental protests in the 1970s halted further planned expansions,” explained Andersson. “The 1980s were prosperous years with strong profits, but during the 1990s, the company faced financial difficulties, leading to several loss-making years.”

In times of profitability, the company has made significant updates to the smelter to ensure its long-term viability. One major modernization took place in 1986. The old smelter (Plant 1) was demolished and immediately replaced with a new, more efficient facility, which was inaugurated on November 26, 1987. Later, in the years 2007 to 2009, KUBAL invested in a modernization project aimed at reducing emissions and increasing efficiency in the electrolyzation process by changing the Söderberg technology to prebake technology. Since then, the company has continued to grow and develop its operations.

KUBAL currently remains one of the largest industrial operations in the Sundsvall region, as well as a key player in Sweden’s aluminum industry, with around 460 employees. The smelter has a production capacity of approximately 130,000 tons of aluminum per year, serving various market sectors that rely on high-quality aluminum products. Due to sourcing its power from renewable energy generation, the smelter is able to achieve emissions as low as 4.45 t CO2e/t Al, far lower than the worldwide average of 12 t CO2e/t Al for primary aluminum (GHG Protocol Scope 3).

New Remelt Capacity for Further Sustainability

KUBAL initiated plans to install a new remelt plant in 2021 with a pre-study analysis and project description, which was finalized in 2024. “The process was complicated by several changes in potential scrap supply and remelting practices applicable for the project,” said Andersson. “But the project team has finally defined the best suitable remelting technology and equipment, the location for the new remelt plant, and internal and external metal logistics.”

After deciding on the parameters and specifications of the project, the company requested quotes from nine potential suppliers that hold leading positions in industry. “All suppliers had a high interest in the project and wanted to deliver best in the class solutions,” noted Andersson. “Due to high competition, the project team had to apply a complex and multifunctional approach in the evaluation and selection of suppliers. The main focus was on efficiency, automatization, and environmental aspects of the equipment. The winner of the selection was Sistem Teknik.”

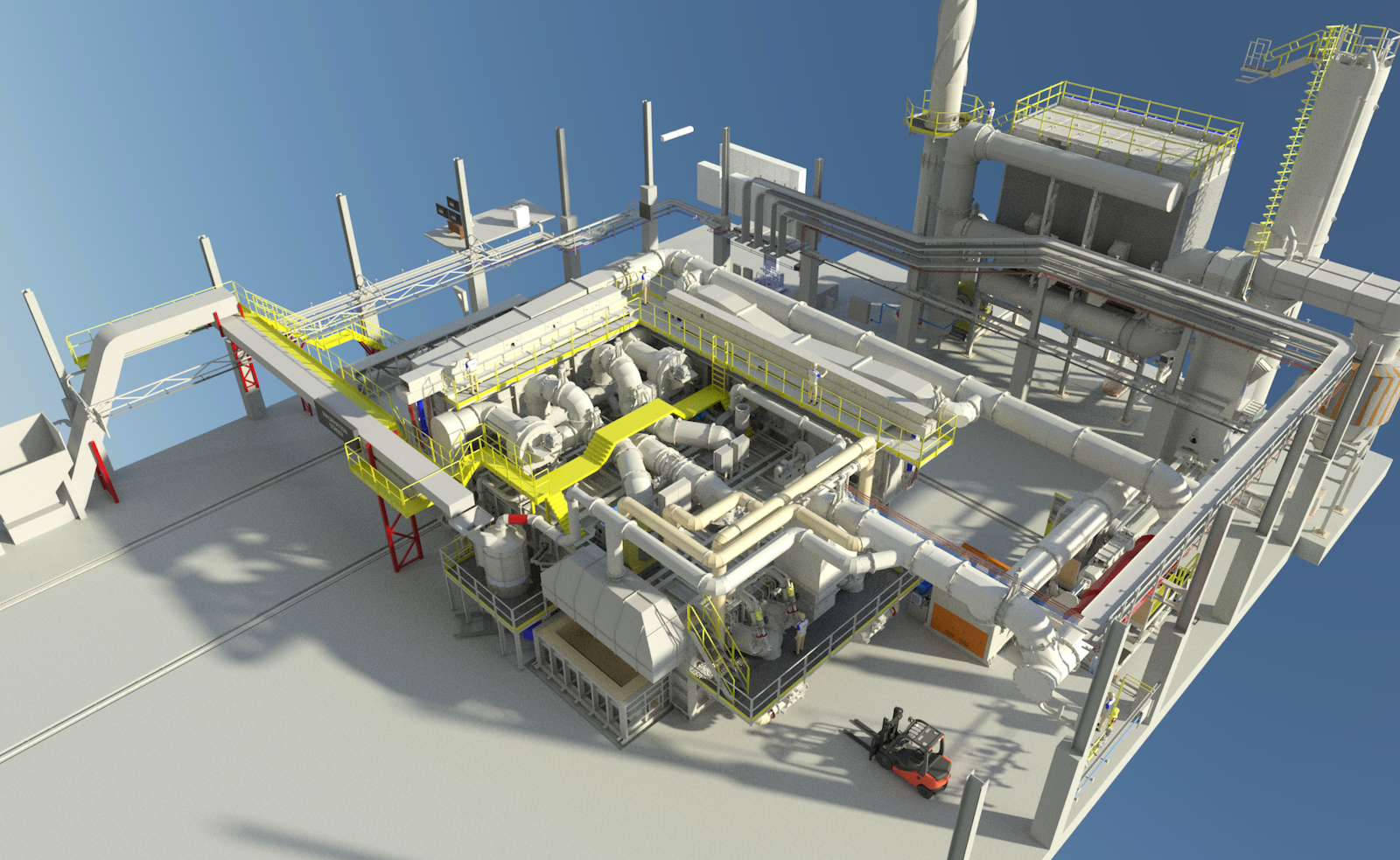

The remelt plant will be constructed in a new standalone building on-site at the smelter. The project includes the installation of a complete remelt plant capable of processing scrap materials, with the melt being transferred into an existing casthouse at the facility. Sistem Teknik is responsible for the design, manufacturing, and commissioning of aluminum melting furnaces and all of the auxiliary equipment for the remelt plant (Figure 2).

The heart of the project will be an 80 ton multi-chamber reverberatory furnace with an integrated Pyrotek LOTUSS chip melting system. The furnace will feature Sistem Teknik’s Phoenix® twin-head regenerative burner system and a cold-air burner, capable of achieving up to 40% energy savings compared to conventional burners by recovering waste heat from exhaust gases. The burners are designed to prevent the flame from coming in direct contact with the molten bath, significantly minimizing dross formation and metal loss. The system is fully controlled through PLC and SCADA architecture, which ensures precise management of air-fuel ratios, furnace pressure, and temperature profiles with complete process traceability.

Every aspect of the melting process will be connected through a unified automation network, embodying the principles of Industry 4.0. High-definition cameras and radar sensors will provide continuous real-time monitoring of furnace operations to measure molten metal levels. The integrated data analytics module enables predictive maintenance, allowing operators to anticipate performance deviations before they occur, thus reducing downtime and optimizing energy use.

Material charging operations will be managed by an automatic charging car, which combines robust mechanical design with intelligent automation. With a 10-ton payload and a 180° rotating body, the charging car is designed to reduce space requirements in the casthouse, while ensuring smooth and efficient material feeding. Equipped with load cells, laser-based positioning, and autonomous navigation via area scanners, the charging car will perform its tasks safely and precisely, synchronizing directly with the furnace control system to optimize cycle times and maintain a balanced thermal load.

In addition, the plant will be outfitted with a fully automated skimming machine, which is powered by advanced image processing and AI-based algorithms. The skimmer is able to identify dross formations on the molten surface and convert these visual patterns into precise movement commands for the robotic arm. This allows for fully autonomous cleaning operations with minimal energy loss and nearly zero metal waste. The system reduces door-open durations, conserves thermal energy, and contributes to safer working conditions by eliminating direct operator exposure to high temperatures. In addition, all motion and safety functions will be managed by redundant PLC logic to ensure uninterrupted operation even under extreme conditions.

Environmental stewardship is a key component of the project’s design philosophy. Fume hoods will be installed above the furnace doors to manage air quality. In addition, a baghouse filtration system, with a capacity of 80,000 m³/h, will capture and filter exhaust gases from the furnace and auxiliary units—with particulate emissions kept below latest European environmental standards. Waste heat recovery and air recirculation systems will further enhance the plant’s energy efficiency. The overall setup is expected to contribute to an estimated 20,000 tons reduction in CO2 emissions per year.

Conclusion

KUBAL has started construction on the new building that will house the new remelt plant (Figure 3). The building is expected to be constructed by 2026, with the completion and startup of the remelt plant to occur in 2027. Once at full capacity, the plant will be able to produce 31,500 tons of molten aluminum per year.

A highlight of the new plant will be its flexible design, allowing KUBAL to incorporate the recycling of scrap aluminum alongside its existing primary production of premium aluminum. By combining recycling and primary production, the company aims to lower the embedded emissions of its products from the current 4.45 t CO2e/t to lower than 4 t/t CO2, which is an important benchmark for the automotive industry. In addition, 3,000 MWh of energy could be reduced per year by utilizing excess heat from the electrolytic aluminum process for the scrap remelting plant.

Editor’s Note: This article first appeared in the December 2025 issue of Light Metal Age. To receive the current issue, please subscribe.