Ferrari revealed the production-ready chassis and components of its new electric car, the Elettrica — the first full-electric model in the company’s history. The model is a key element in the company’s multi-energy strategy, which encompasses internal combustion engine (ICE), hybrid electric (HEV), plug-in hybrid electric (PHEV), and fully electric powertrains.

“With the new Ferrari Elettrica, we once again affirm our will to progress by uniting the discipline of technology, the creativity of design and the craft of manufacturing,” said John Elkann, executive chairman of Ferrari, during Capital Markets Day 2025. “These milestones reflect our deepest commitment: to our people, to Italy, and to ensuring that Ferrari remains unique.”

According to Ferrari, the company would only introduce an electric car “once the technology available could ensure the superlative performance and authentic driving experience befitting the values of the brand.” As a result, the development of the Ferrari Elettrica follows years of technological research into electrification, beginning with hybrid models. These previous developments enable the company to develop the technical know-how to engineer an electric car that would meet the high expectations of the engineers and customers.

The Elettrica boasts over 60 patented proprietary technological solutions. Notably, both the chassis and body shell will be manufactured with 75% recycled aluminum for the first time, contributing to an astonishing overall saving of 6.7 tons of CO2 for every vehicle built.

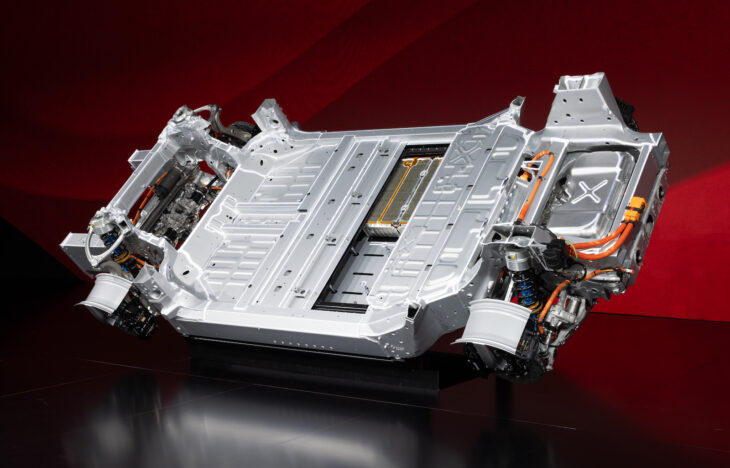

Aluminum Structure

The chassis of the new Ferrari Elettrica has an extremely short wheelbase, which places the driver near the front wheels to offer dynamic feedback while driving, facilitate accessibility, and maximize comfort. This layout combined with the higher overall weight of an electric car presented significant engineering challenges, especially regarding energy absorption in the event of a crash. Therefore, the company engineered the front shock towers to absorb energy during impact and positioned the front and inverter in such a ways as to dissipate energy before it reaches the chassis nodes — maximizing safety and preserving structural integrity.

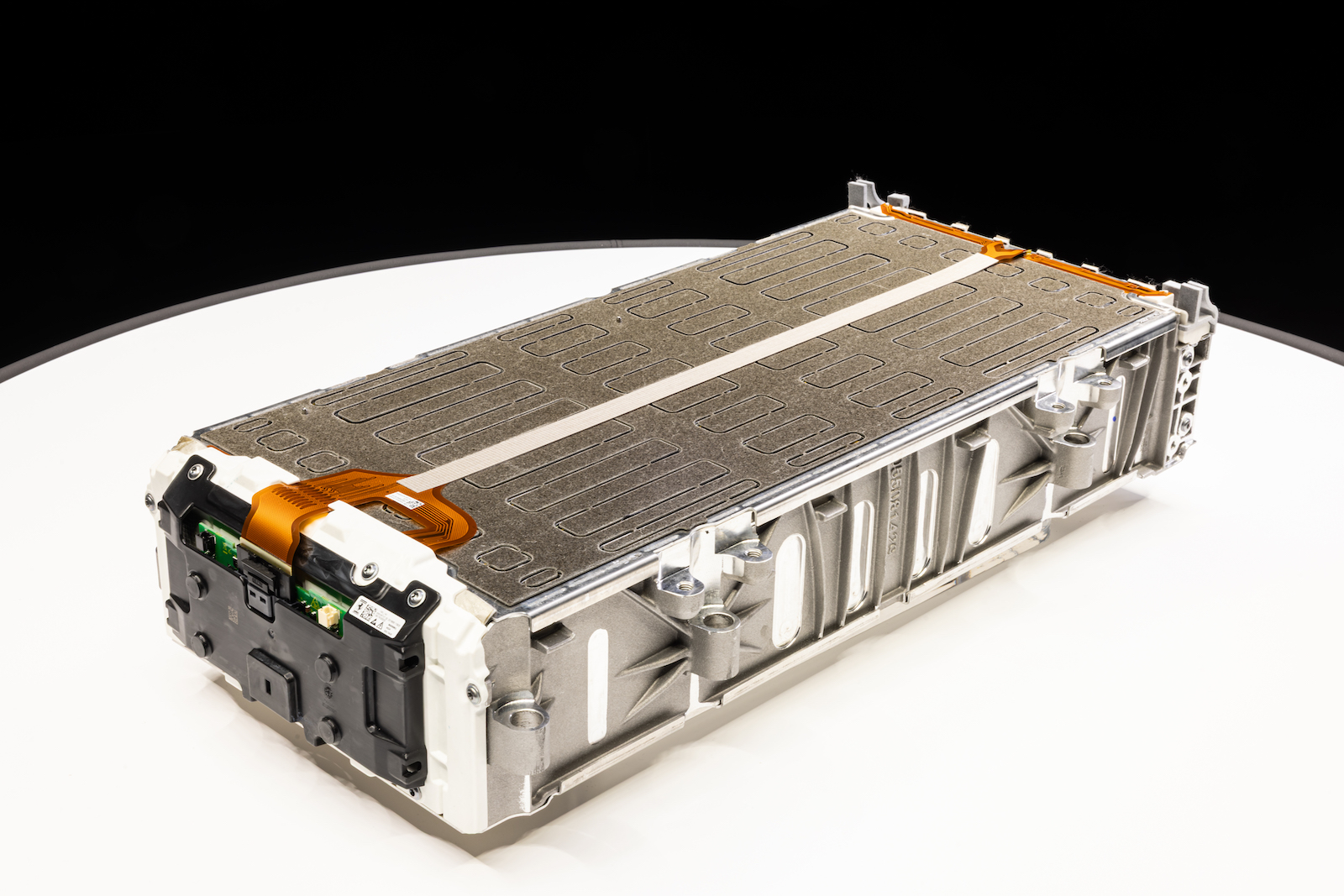

Designed and assembled completely in-house by Ferrari, the battery is integrated into the floorpan, thus lowering the center of gravity by 80 mm over an equivalent ICE model. A global structural approach was used to reduce the weight, resulting in the battery pack being wrapped in an aluminum shell structure. In addition to the aluminum shell, the battery is being protected from potential impact by the chassis itself.

The gap between the cells and the side sills acts as an energy-absorbing crumple zone during a side impact, while also housing the cooling lines. The same principle was also applied for front and rear crash protection, in which the battery module is placed in the middle, with the area around being used as energy-absorbing zones.

To ensure protection against any accidental impact from underneath, the cells are suspended from the floor to create an energy-absorbing gap. As part of the aluminum shell structure, the protective shield is combined with three aluminum cooling plates that incorporate a set of internal pipes. This improves the efficiency of the design and minimizes the weight of the chassis.

The front and rear axles are each comprised of two independent electric engines — all developed in-house by Ferrari. The transmission, inverters and electrical engines are all designed to achieve excellent control, power density, electrical efficiency, and low noise emissions. The castings for these components are fabricated in-house at Ferrari’s own foundry, allowing for tight control of the production process and ensuring impeccable build quality. All castings are produced with secondary aluminum alloys, which cut CO₂ emissions by up to 90% compared with conventional alloys, without comprising mechanical performance.

The Elettrica is now ready to go into production, with deliveries expected to commence in late 2026.

Technology and Decarbonization Goals

During Capital Markets Day 2025, Ferrari also discussed its future strategies. The company is focused on providing customers freedom of choice when it comes to powertrains, leading to product diversification. The company plans to launch four new cars per year between 2026 and 2030. By 2030, its product line-up will include 40% ICE, 40% hybrid, and 20% electric vehicles, such as the new Elettrica.

As part of this diversification, the company plans to invest in research and development for its next generation of sports cars, with a variety of areas of exploration. This includes exploring improvements in the electric powertrain to enhance performance and consideration of new and innovative materials aimed at sustainability, weight management, and specific applications, including cooling of the engine and components.

In particular, Ferrari plans to use specialized recycled aluminum alloys in the body-in-white and in the in-house castings manufactured for its vehicles. This is expected to lower CO2 emissions by over 75% compared to virgin aluminum, and contributing to an overall reduction of ~6% in Ferrari’s total Scope 3 CO2 emissions by 2030 compared to 2024.