Bauxite residue, also known as “red mud,” is a hazardous by-product of aluminum production. Each year, millions of tons of red mud accumulate and is pumped and deposited into land-based lagoons, ponds, and impoundments. Since the red mud contains harmful metals, disasters related to its storage have caused river contamination and flooding in affected communities — making it a significant environmental hazard that aluminum companies, organizations, and universities have been working to address for decades.

Recently, Rice University completed research and development on a faster and cleaner method for recovering aluminum and removing toxic metals from red mud. This new technique, published in American Chemical Society Applied Materials and Interfaces, involves a brief electrical pulse lasting under one minute along with a small amount of chlorine gas. If implemented on a larger scale, it could revolutionize global waste management and materials recovery.

“Our research presents a potential game-changing solution for the red mud crisis,” said James Tour, the T.T. and W.F. Chao Professor of Chemistry and professor of materials science and nanoengineering at Rice University, and the study’s corresponding author. “This advance is massive from an industrial perspective, turning what was once a toxic liability into a valuable asset in under one minute.”

The New Electrical Flash Process

With funding from the Air Force Office of Scientific Research and the U.S. Army Corps of Engineers, the research team at Rice University aimed to explore whether this waste could be repurposed rather than merely contained. Their work resulted in a process that uses flash Joule heating (FJH), which delivers electricity in a quick flash, similar to a bolt of lightening.

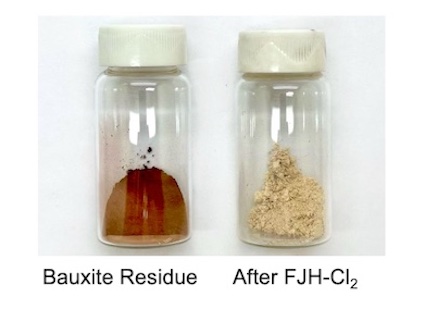

With this new method, FJH is combined with chlorine gas to rapidly heat the bauxite residue with a short, high-power electrical pulse to vaporize iron and other toxic metals, leaving behind a residue rich in aluminum. This aluminum-rich material can then be repurposed into durable ceramic tiles or bricks or can be re-subjected to the normal aluminum smelting process. The breakthrough offers a practical and scalable solution to address a significant pollution problem by transforming it into valuable materials, marking an advancement in industrial waste recovery.

This process is significantly faster and cleaner than traditional methods, which often require prolonged heating in furnaces or the use of corrosive chemicals. The new method uses no water and no solvents, while also removing the sodium salts in the process, relieving the end use of the typically caustic red mud. According to the research team, the approach offers a threefold advantage — reducing waste piles, cutting greenhouse gas emissions, and decreasing the need for new bauxite mining.

“The speed and simplicity of this method set it apart,” said Qiming Liu, a postdoctoral researcher at Rice and a co-first author of the study. “In just 60 seconds, we extracted 96% of the iron and nearly all the toxic species, while retaining almost all the aluminum.”

Enabling Future Sustainability

Shichen Xu, a postdoctoral researcher at Rice and co-first author of the study, noted that this method could not only address red mud, but could also address high-volume waste streams in other industries, such as steel manufacturing, mining, and rare earth processing. “What was once an environmental threat can now be transformed into building materials,” said Xu. “We have turned cleaned red mud into ceramics that are super hard, making them suitable for construction and aluminum recovery.”

Tour added, “This is not just about red mud; it’s about changing our perspective on waste. If we can apply this method to other industrial residues, it could represent the beginning of a new era in sustainable materials recovery.”

Currently, the process is being scaled Flash Metals USA, a Rice spinoff company and a division of Metallium Ltd.. It will be deployed in partnership with aluminum production companies around the world.

Read the full study: “Iron and Heavy Metal Removal from Bauxite Residues by Flash Joule Heating with Chlorination,” by Qiming Liu, Shichen Xu, Phelecia Scotland, Justin Sharp, Yi Cheng, Jaeho Shin, Nicholas Lowell Viscomi, Lucas Eddy, Shihui Chen, Bowen Li, Tengda Si, Carter Kittrell, and James M. Tour from Rice University, and Mine G. Ucak-Astarlioglu from the U.S. Army Engineer Research and Development Center, published in American Chemical Society Applied Materials and Interfaces.