Experienced welders will tell you that, compared to welding steel, welding aluminum and its alloys is not difficult but different. Steel, being one of the common construction materials, most welders and myself included started by learning how to weld steel. As aluminum has especially gained market share in transportation, welding aluminum is challenged in various […]

welding

-

-

Posted in:

ARTICLE: Nanotechnology-Enabled Welding and Manufacturing of High Performance Aluminum Alloys

Lightweighting has been and continues to be a major concern for the aerospace, automotive, and transportation industries. Whether it’s an airplane, automobile, boat, or train, the use of lightweight materials, such as aluminum, provide significant fuel savings and performance benefits. Like its competitors in the lightweighting arena (steel, composites, etc.), aluminum is working to continually […]

-

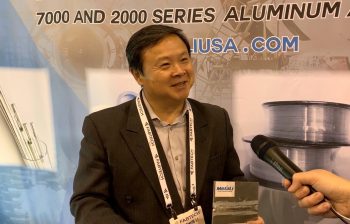

FABTECH 2019, North America’s largest metal forming, fabricating, welding, and finishing, was held on November 11-14 in Chicago, Illinois. The event achieved record attendance, with a total of 48,278 attendees from 95 countries over the course of four days. During FABTECH, Light Metal Age spoke with Prof. Xiaochun Li, founder of MetaLi, about the company’s groundbreaking […]

-

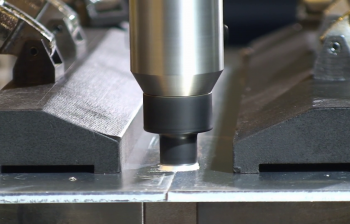

The Materials Testing Institute at the University of Stuttgart has developed a process, based on friction stir welding (FSW), for the high-strength welding of aluminum and steel plates. The plates can have different thicknesses and the seam is so stable that the hybrid plates can even be deep drawn. This enables lightweight yet sturdy hybrid […]

-

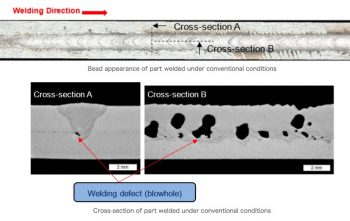

The demand for lighter automobile bodies in order to provide improved fuel efficiency and reduced CO2emissions has increased in recent years, and various types of aluminum alloys are now being used for automobile parts in an increasingly broad range of ways. Furukawa Electric Co., Ltd. in Japan developed a new fiber laser welding technology said to address […]

-

Taber Extrusions, an NMLP group company, installed a new friction stir welding (FSW) line at its Russellville, Arkansas, manufacturing facility for the aerospace, rail, automotive, marine, transportation, and other industries. With this machine, Taber will be able to weld large double sided thick profiles with minimal cycles of the machine, providing greater efficiency and more precise results. […]

-

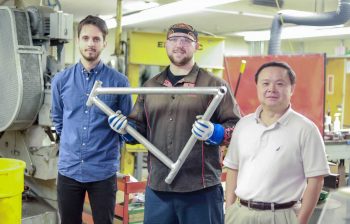

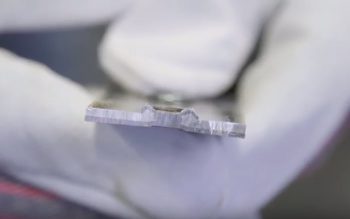

Engineers at the UCLA Samueli School of Engineering developed a method for welding AA7075 alloy. Developed in the 1940s for the automotive industry, the alloy that is nearly as strong and one-third its weight, but traditionally has been almost impossible to weld together using the techniques commonly used by auto makers for the assembly of […]

-

US9951971 — SOLAR MIRROR ARRAY SYSTEM, METHODS AND APPARATUSES THERETO — Werner Extrusion Solutions LLC (USA) — An apparatus for transferring force to a frame of a solar mirror array. The frame has at least one structural element. The apparatus includes a torque plate. The apparatus includes at least one node attached to and in […]

-

Responding to the growing industry trend towards multi-material part design, Alcoa has developed an advanced new joining technology. Resistance spot riveting (RSR™) was developed join dissimilar materials (aluminum, high strength steels, magnesium, and composites) using the same equipment implemented for conventional spot welds, providing automakers the flexibility to switch between RSR and conventional welds, depending on […]