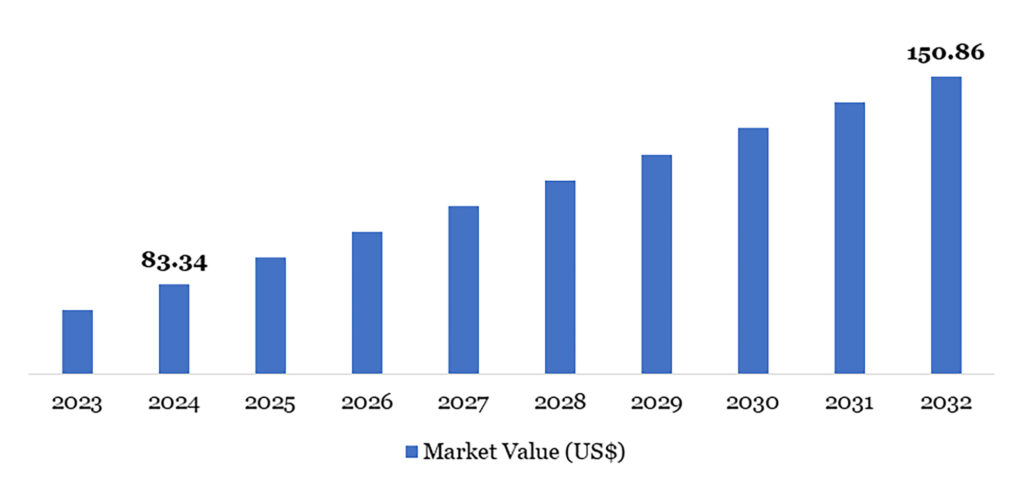

Editor’s Note: Aluminum sheet and strip market forecasts vary depending on which company is creating the projections. However, all of them are forecasting decent market growth over the next seven to eight years.

For the period from 2025 to 2032, the projections are showing annual market increases ranging from 6% to 8%, with the key sectors—automotive, aerospace, construction, packaging, and electrical applications—being pretty much unchanged. Concrete examples include strong anticipated growth in urban infrastructure in China, India, and the U.S., which is leading to increased consumption of sheet in cladding, roofing and facades.1 More renewable energy projects are also on the horizon, according to Mordor Intelligence.2

When it comes to products, coiled sheet remains highly attractive, and is actually dominant in the automotive, construction, and manufacturing industries. The flat sheet segment holds a strong position in applications related to appliances, packaging, and consumer electronics, where outstanding surface finish and high corrosion resistance among are the biggest concerns.

Looking forward, when it comes to regions, Asia Pacific is leading the way, accounting for the lion’s share of the aluminum sheet strip market—and that is not likely to change. That said, each of the key regions, as follows:3

- Asia Pacific is realizing high growth thanks to rapid industrialization, urbanization, and a growing middle class.

- Europe is focusing on sustainability and environmental protection, with an established industrial base and regulatory framework.

- Latin America is showing decent potential and continued industrial growth, primarily in Brazil, Mexico, and Argentina.

- Middle East and Africa is an emerging region due to infrastructure development and economic diversification, with the UAE, Saudi Arabia, and South Africa leading the way.

- North America is benefiting from an advanced technological infrastructure and supportive regulatory environments in the U.S. and Canada.

References

- “Aluminum Sheet Market Size, Share & Industry Analysis 2025-2032,” Data Intelligence, www.datamintelligence.com/research-report/aluminum-sheet-market.

- “Aluminum Market Growth Report – Aluminum Market Insights 2025,” Mordor Intelligence, www.mordorintelligence.com/industry-reports/aluminum-market.

- “Aluminum Sheet Strip Market Overview,” www.marketsizeandtrends.com/report/aluminum-sheet-strip-market.

— Kevin Widlic, Editor

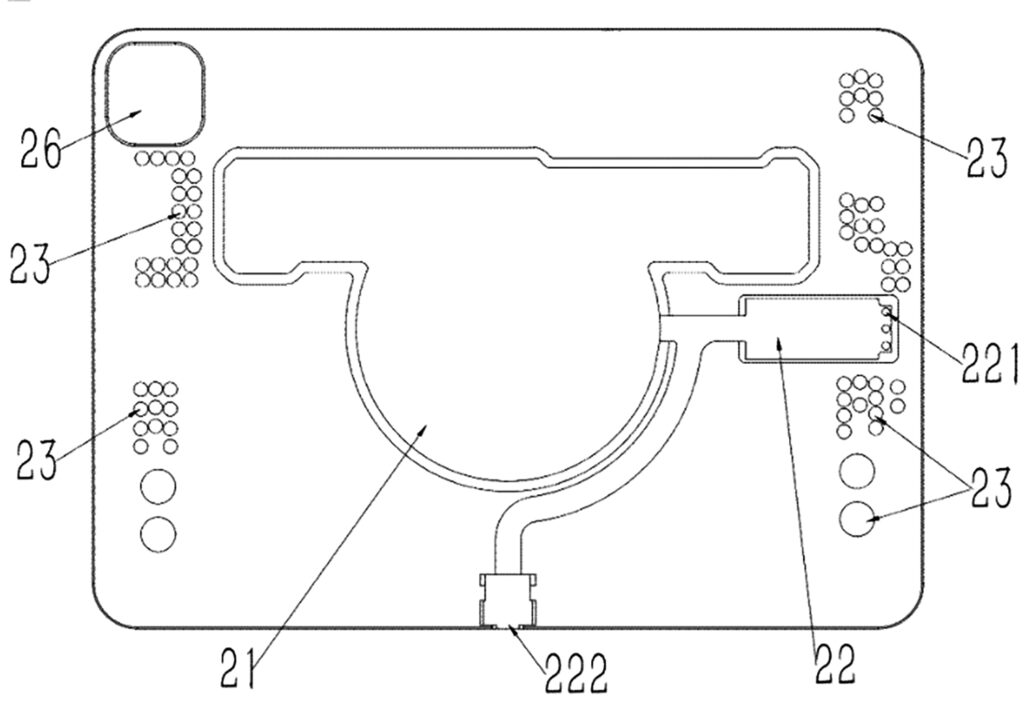

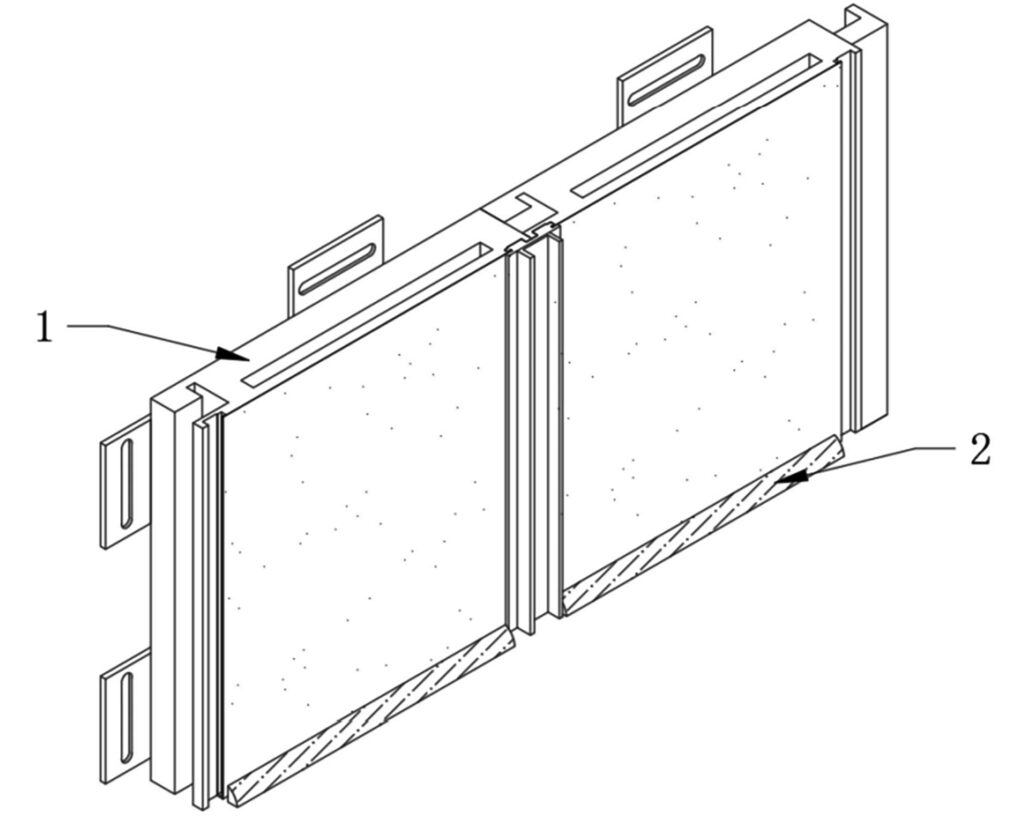

US12287508B1 — Luminous board with aluminum alloy frames — Xian Shao (China) — Luminous finished panels are sheet materials widely used in lighting and decorative fields. The luminous decorations refer to products that can emit light at night or in the dark through built-in light sources. However, there are heat dissipation issues for the existing products during use. Specifically, when light-emitting diode (LED) light sources of the existing luminous panels emit light, most of electrical energy from the panels is converted into heat rather than light energy during operation of the LED light sources. This panel addresses the heat dissipation concerns by providing a luminous finished board that can reduce temperature generated by an operation of light strips and achieve cooling of the strips, thereby improving a service life of the light strips and reducing the maintenance frequency of the device. The technical solution: A luminous finished board includes a wooden frame. The wooden frame defines a first placement groove and a second placement groove therein, a first aluminum alloy frame and a second aluminum alloy frame are attached onto the first placement groove through double-sided adhesive or adhesive, and sides of the first aluminum alloy frame and sides of the second aluminum alloy frame are each in contact with inner walls of the first placement groove. Each of the aluminum frames defines a plug-in cavity. A light guide plate is inserted in the plug-in cavity, and sides of the light guide plate are surrounded by a light strip, the light strip is in contact with inner walls of the plug-in cavity. A control circuit board and a battery are attached onto the sides of the light guide plate through the double-sided adhesive or the adhesive. The light strip and the battery are both electrically connected to the control circuit board, and a sealing plate is attached onto the second placement groove through the double-sided adhesive or the adhesive and is configured to seal the wooden frame.

US12440064B1 — Multi-ply cookware with thermal layer of aluminum — Gizmatic LLC (USA) — Multi-ply cookware that is durable and corrosion resistant while also providing better heat distribution and a seasonable cooking surface is disclosed. The body of the multi-ply cookware may include a cooking surface layer, one or more thermal layers disposed below the cooking surface layer, and a protective layer disposed below the thermal layers. The cooking surface layer may be composed of carbon steel. The thermal layer may be composed of aluminum. The protective layer may be formed of stainless steel. These layers may be roll-bonded together.

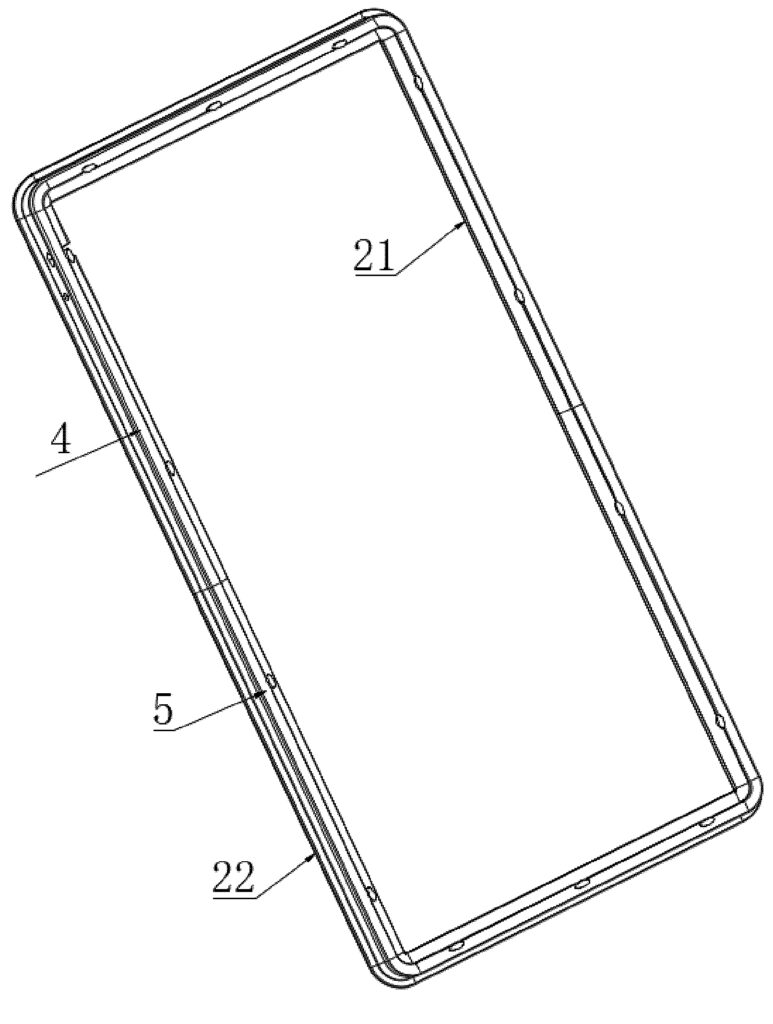

US12326215B2 — Tablet stand with aluminum cooling unit — Shenzhen Zhenting Trading Co Ltd (Canada) — Tablet stands are designed specifically for tablets to improve the comfort and convenience of using tablets in various environments and occasions. The angles of the popular tablet stands on the market are usually adjustable according to personal preferences and needs. However, given the limited battery life of tablets, users often need to recharge tablets during use. When the tablet is connected to the charging cable, adjusting the angle of the stand or moving the stand may interfere with the charging cable, resulting in poor contact of the charging cable and the tablet. This may force users to frequently reconnect the charging cable, which may damage the charging cable and the tablet’s charging port. To overcome these defects, this invention provides a tablet stand, which includes a charging device that can be connected to an external power supply. Putting a tablet on the said tablet stand then recharges the tablet, without interference even if users move the stand or adjust its angle. Further, when the tablet is put on the supporting assembly, the aluminum cooling unit (21) can help the tablet dissipate heat.

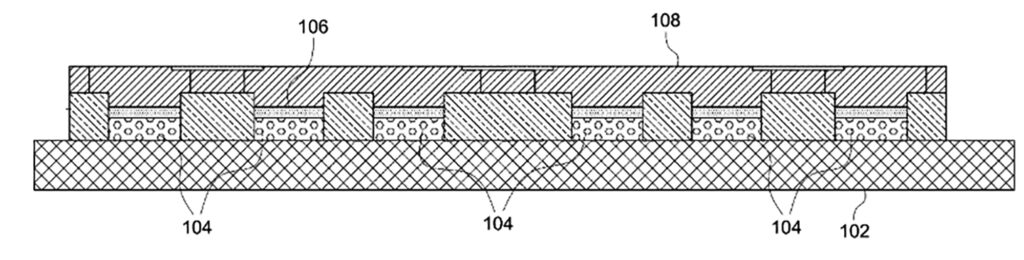

US12322676B1 — Baffles for electronic circuits immersed in cooling fluid in a tank — Auradine Inc (USA) — In various industrial and electronic applications, mechanisms are used to regulate the temperature of electronic circuits during operation. These mechanisms include boilerplates or other structural elements or materials for facilitating thermal management. This disclosure describes methods and systems for providing cooling solutions in immersion cooling systems, including baffle covers to regulate agitation of the cooling fluid. In some implementations, the boilerplate (108) can be made of a metal with high thermal conductivity, such as aluminum, to transfer heat away from IC chips (104) to a larger cooling system, such as an immersion cooling system. This maintains operating temperatures and ensures the performance, reliability, and longevity of the IC chips.

US12377340B1 — Snow-sliding devices and methods of manufacture — Renoun LLC (USA) — A snow-sliding device includes a core, a plurality of securing elements including a base with a sliding surface, a top surface, and at least a sidewall. Snow-sliding devices such as skis and snowboards are constructed from multiple components and materials in order to meet several mechanical requirements and design goals, such as giving a user an ability to maneuver the devices over snowy surfaces, minimizing vibration or “chatter” of the devices as they slide, as well as striking a balance between rigidity, flexibility, and durability of the devices. Unfortunately, existing methods for constructing snow sliding devices do not have an effective way to account for the variability of conditions under which such devices may be operated, or to limit vibration satisfactorily under more challenging conditions. In some cases, a reinforcement element may include one or more layers of aluminum textured with titanium.

US12444520B2 — Low-profile cable armor — AFC Cable Systems Inc. (USA) — This armored cable assembly may include a plurality of conductors and a metal sheath disposed over the plurality of conductors. The metal sheath may have a plurality of revolutions extending helically along a lengthwise axis, each of the plurality of revolutions including a first section having a curved profile, a second section extending from the first section, the second section having a planar profile, and a third section extending from the second section. Armored cable and metal-clad cable provide electrical wiring in various types of construction applications. These cables house electrical conductors within a metal armor. The metal armor may be flexible to enable the cable to bend while still protecting the conductors against external damage during and after installation. The metal armor which houses the electrical conductors may be made from aluminum, and the metal sheath may be formed of aluminum strip.

US12366188B1 — Heater for exhaust pollution mitigation — ECC Tec MSJ Inc. (USA) — The embodiments of this disclosure overcome the limitations of existing exhaust systems by providing a versatile solution for pollution mitigation in vehicles, power plants, and industrial facilities. The proposed heater and the system and method enhance the efficiency of pollutant removal, reduce operational costs, and promote environmental sustainability. Overall, the present disclosure represents a significant advancement in the field of exhaust systems and associated methods for pollution mitigation, such as in vehicles, automobiles, trains, marine vessels, construction equipment, agricultural machinery, power plants, and industrial facilities. The ceramic holder assembly includes a bracket which is coupled to the housing, and a vibration dampener positioned between the ceramic holder and the bracket to assist in dampening vibrations of the heating element. The vibration dampener is an S-shaped strip of metal material that is bent or formed in the shape of the letter “S.” This strip can function as a spring to allow it to store and release energy. It may be made of aluminum, which provides appropriate thermal and mechanical properties for vibration dampening and resisting the high temperatures of the heater.

US12403842B1 — Multi-sport rack that is reversibly attachable to a pickup truck bed — Russell Sutliff (USA) — The multi-sport rack of this invention sits on either side of the truck bed like a saddle bag to provide clearance for the bed shell or bed cap. Each multi-sport rack can hold a bicycle, snow boards, surf boards, and/or skis. The rack includes a special base plate assembly that is a custom-shaped rigid plate assembly designed to yield high strength and rigidity. The base plate assembly (10) is the primary source of the substantial rigidity and sturdiness of the rack, and it may be made of aluminum, preferably as a one-piece structure.

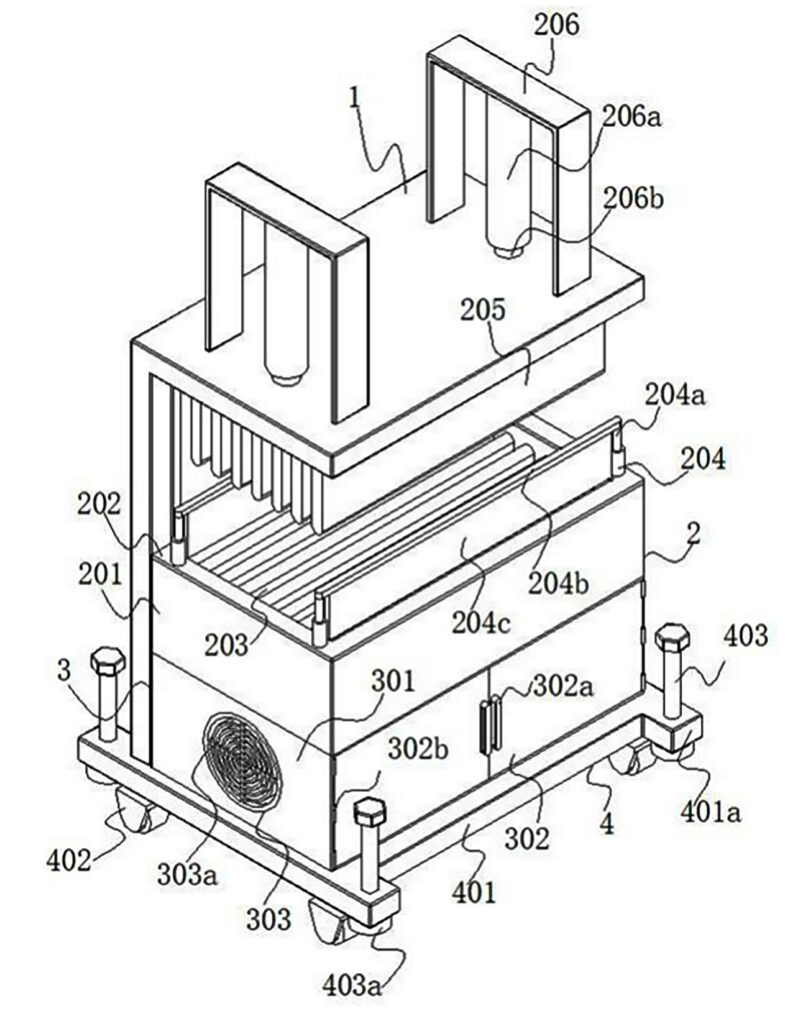

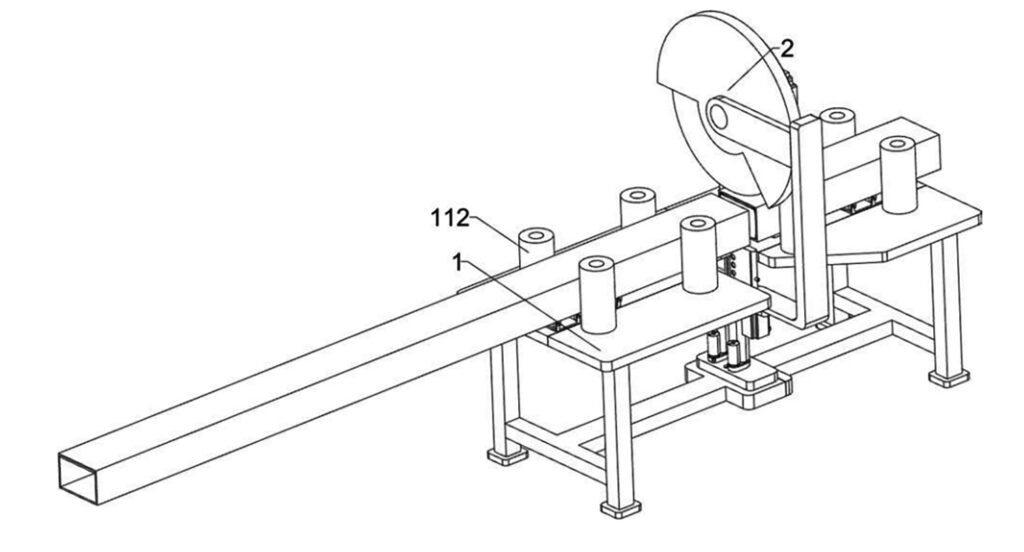

CN119328216B — Aluminum product shearing equipment — Jiangsu Daiwen Exhibition Co., Ltd. (China) — The invention relates to the field of aluminum shearing, and in particular to shearing device for aluminum display rack processing. It includes a workbench, a cutting device, a driving assembly, an electromagnet, a magnetic sheet, a push rod I, a rotating block I, a support rod, a telescopic rod and a support block. The workbench is fixedly connected to the driving assembly, the driving assembly is connected to the cutting device, the driving assembly is connected to the electromagnet, the electromagnet is magnetically connected to the magnetic sheet, the magnetic sheet is fixedly connected to the support rod, and the support rod is connected to the rotating block I. The rotating block I is rotatably connected to the telescopic rod and the telescopic rod is connected to the support block. The invention supports the inside of the aluminum bar through the support block, so that the cut part of the bar cannot bend and deform inward.

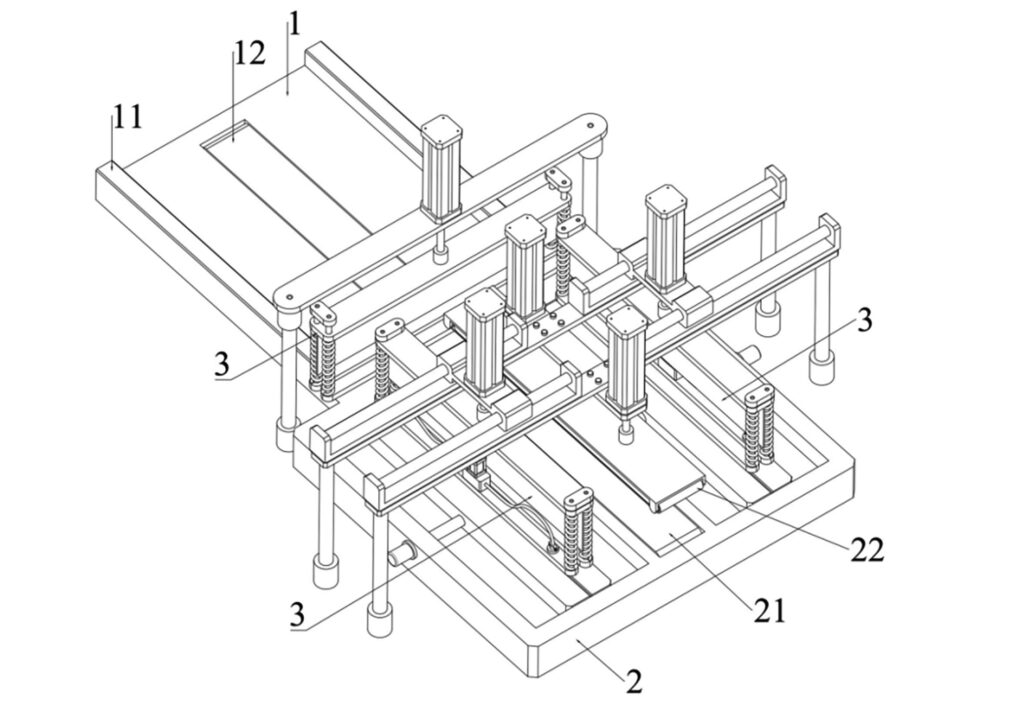

CN118699079B — Roller lubricating device for rolling aluminum alloy thin strip — Shanghai Duofu Zhongyun Aviation Technology Co., Ltd. (China) — During the metal rolling process, lubrication of the rolling equipment is one of the necessary processes to keep the rolling equipment working stably and improve its service life. It is also important to note that the increase in roller surface temperature will cause adhesion to form on the surface of the rolled material. In the prior art, lubricating oil is often applied manually on the roller surface regularly. However, it is difficult to lubricate the rolling equipment in real time by manual operation. The purpose of this invention is to provide a roll lubrication device for rolling aluminum alloy thin strips, to solve the problems raised above. To achieve the purpose, the invention provides a roll lubrication device for rolling thin aluminum strips, comprising a base, a workbench fixed on the base, a roll frame fixed on the workbench, and two rolls arranged in upper and lower positions on the roll frame, and also comprising a lubrication mechanism arranged on the workbench.

CN119253204B — Aluminum sheet bracket for e-car battery modules — Laimu Electronics Jiangsu Co., Ltd. (China) — The invention provides an aluminum sheet support of a battery module, which belongs to the technical field of power batteries and comprises an aluminum sheet terminal, a plastic support and a battery module, wherein the aluminum sheet terminal is provided with two electrode installation seats and two installation parts. The aluminum sheet terminal is symmetrical relative to the center of a geometric center, the plastic support is provided with a through hole matched with the outer contour of the aluminum sheet terminal, two splicing parts are arranged in the through hole, and the two installation parts are fixedly connected with the two splicing parts. This structure reduces the probability that the aluminum sheet support will be damaged in the preparation, transportation and assembly processes.

CN223319036U — An aluminum shell for LED light strip that is easy to dissipate heat — Foshan Jiatu Culture Technology Co., Ltd. (China) — In the prior art, the light bar inside the aluminum shell cannot effectively dissipate heat, thereby reducing the service life of the light bar. To overcome these defects, the invention provides a LED light bar aluminum shell convenient for heat dissipation, which absorbs and releases heat through the semiconductor refrigeration piece and guides out the heat released by the semiconductor refrigeration piece to the outside of the body through the side heat conduction patch. The LED light bar aluminum shell comprises a U-shaped body, a light bar is installed on the bottom wall of the body, light-transmitting glass is installed at the top end opening of the body, a bottom installation foot is formed at the bottom end of the body, a heat dissipation cavity is formed between the bottom installation foot and the bottom end of the body, a semiconductor refrigeration sheet is attached to the top wall of the heat dissipation cavity, side heat conduction patches are attached to the bottom end of the semiconductor refrigeration sheet. Further, connecting grooves are formed in two sides of the heat dissipation cavity in a penetrating mode through the body, and the side heat conduction patches penetrate through the connecting grooves and are attached to the side ends of the body.

CN223070506U — Fin-cutting device — Mianyang High New District Shengke Electronic Technology Co., Ltd. (China) — A fin evaporator is a heat exchanger mainly used in refrigeration and air-conditioning systems. They are typically composed of fins, tubes, frames, connectors, the fins typically being made of thin metal sheets of aluminum to increase the surface area of the evaporator and thereby enhance performance. In the prior art, aluminum strips are cut into fins, the cut fins are punched and punched, and the formed fins are overlapped. At present, when the aluminum strips are cut into the fins, the lengths of the fins can be generally controlled, but the widths of the fins cannot. To solve this, the new application provides a fin cutting device that can cut fins with different lengths and widths. The model provides a fin cutting device, which relates to fin evaporator processing technology and comprises a feeding plate, a bearing plate, and a cutting mechanism.

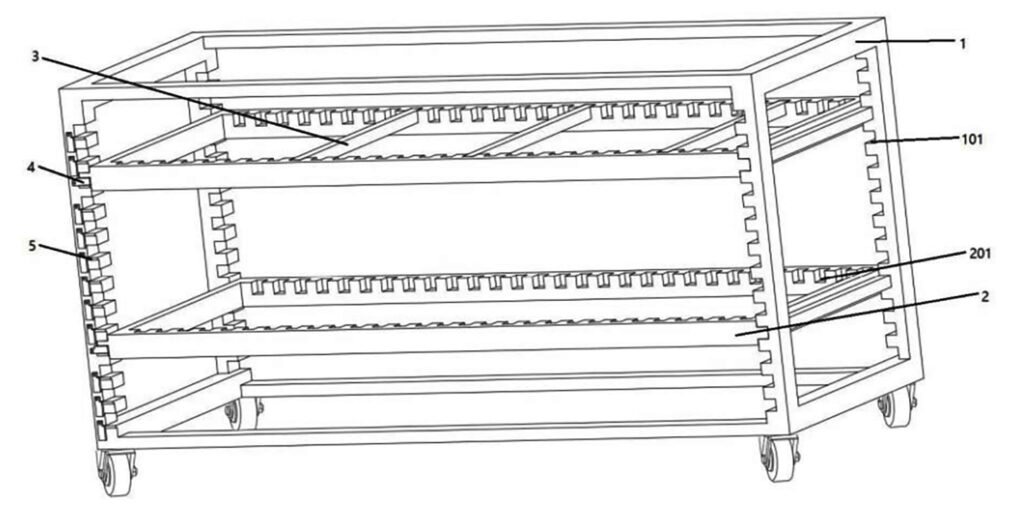

CN222945529U — Strip-type aluminum storage rack — Shandong Songaluminum Precision Industry Co., Ltd. (China) — In the preparation processing of aluminum plate, the plate generally can’t stack. More space is required. Consequently, a nimble storage rack that is also mobile is required. This model – the strip-shaped aluminum plate storage rack – is simple in structure, flexible to move and capable of simultaneously placing various types of aluminum plates. The storage rack comprises an outer frame, support frames, support rods and limit buckles, where the support frames are at least two and are arranged in parallel, and are detachably connected with the outer frame to form a multi-layer combined storage rack. The support rods are detachably connected with the mutually parallel support frames, the placement direction of the support rods perpendicular to the aluminum plate. The temporary placing frame can be assembled according to the specification of the aluminum plates. The frame has a simple structure, saves space and time, and ensures operator safety.

CN119406960B — Production method of 7xxx series aluminum alloy narrow thin strip — Hunan Qianlong New Material Co., Ltd. (China) — Because 7xxx series aluminum alloys are strong and difficult to bend by external force, some high-end electronic brands have begun to adopt these alloys in their smart phones, tablet computers and the like. At present, the conventional production process of 7xxx series narrow coil thin strip adopts a semicontinuous ingot casting-hot rolling method. This process is suitable for the production of large quantities of sheet strip, but not for the production of narrow thin strips for consumer electronics. To resolve these shortcomings and disadvantages, the new invention provides a production method of 7xxx series aluminum alloy narrow strip that utilizes the characteristics of rapid cooling continuous casting and rolls into coiled sheets by using the outlet waste heat of the round rod materials, so as to replace the traditional semi-continuous ingot casting-hot rolling process. Consequently, equipment such as a large-scale aluminum alloy semi-continuous slab ingot casting machine, an ingot homogenizing furnace, a hot rolling mill and the like, are not needed.

CN223088708U — Aluminum veneer curtain wall with waterproof structure — Guangdong Tengmu Metal Building Materials Co., Ltd. (China) — Aluminum veneers have good processing performance, changeable modeling and appearance colors, and ease in cleaning and maintaining, aluminum veneers are often used in curtain wall construction, thereby providing an attractive appearance for the outer wall and protecting the building from the external environment. This model discloses an aluminum veneer curtain wall with a waterproof structure, including an aluminum veneer body, in which the surface of the body is connected with an arc-shaped waterproof strip, and a sound insulation component is arranged inside the body. When in use, after a plurality of aluminum veneer bodies are spliced together, a section of the arc-shaped strip will be stuck on the upper surface of another aluminum veneer body, and the waterproof card plate is inserted within two adjacent card slots. If it rains, water flows out from the drainage frame strip, and the arc surface of the arc-shaped waterproof strip reduces the accumulation of water, thereby achieving the effect of reducing water penetration. It also avoids the traditional sealing method of glue or sealing strips, which cause aging and corrosion over time, thereby improving the service life of the aluminum veneer and the protection of the wall.

CN223355125U — Water-soluble coated aluminum sheet — Kunshan Haoruiguan Electronic Materials Technology Co., Ltd. (China) — Today, existing aluminum plate can corrode when meeting water. This is more obvious under humid climate conditions, where the aluminum plate is thinner and lighter and has no supporting force. The new model aims to solve these problems by providing water-soluble film-coated aluminum sheet. In this model, a first water-soluble film and a second water-soluble adhesive are arranged on one side of a first aluminum sheet and a second aluminum sheet. The thickness of the first aluminum sheet and the second aluminum sheet is 0.11 mm. The first water-soluble film and the second water-soluble adhesive protect the first aluminum sheet and the second aluminum sheet. The first aluminum sheet and the second aluminum sheet will corrode and affect their use when exposed to water. The first water-soluble adhesive and the second water-soluble adhesive are arranged on one side of the first aluminum sheet and the second aluminum sheet for bonding and connection. The materials used for the waterproof film are polyvinyl alcohol, chitosan, gelatin, casein, and gum arabic. The adhesive is made with polyvinyl alcohol adhesive or carboxymethyl cellulose glue. The glue formed after being easily dried in water has good hardness and water resistance.

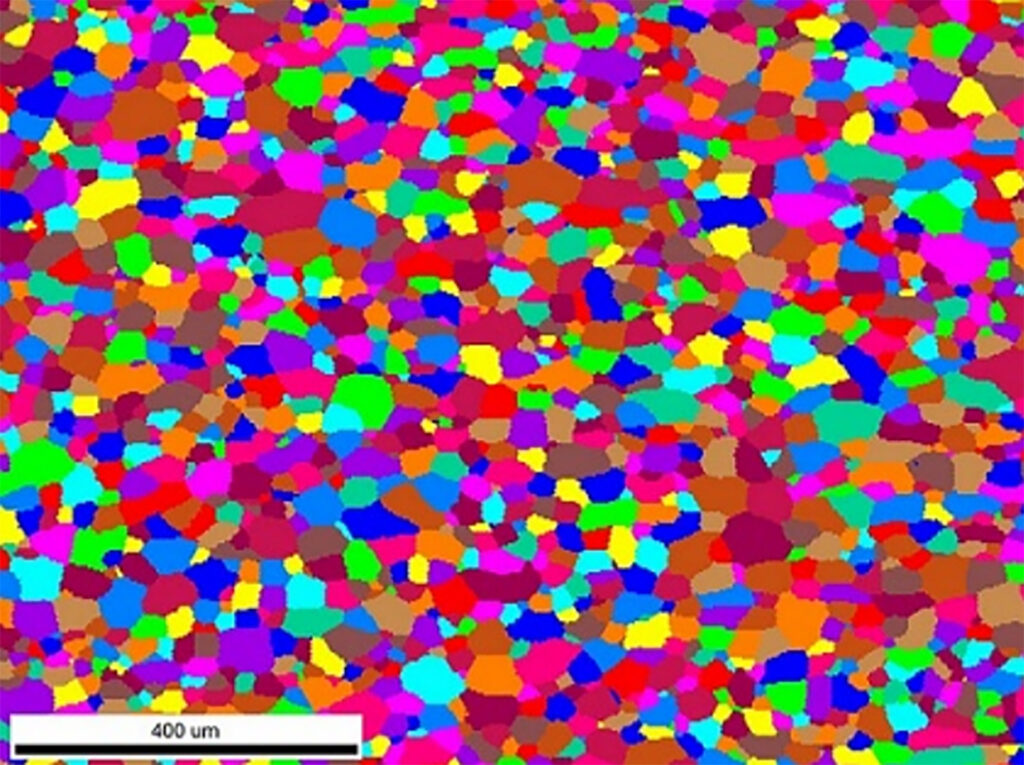

CN118957367B — 6xxx series aluminum alloy material for automobile body panels and low-carbon preparation — GRIMN Engineering Technology Research Institute Co., Ltd. (China) — The 6xxx series aluminum alloy material for automobile body panels is composed of: Ho 0.05-0.12wt.%, Mg 0.45-0.65wt.%, Si 0.85-1.10wt.%, Cu 0.05-0.20wt.%, the remainder being Al and unavoidable impurities – and the Mg/Si content ratio is 0.4-0.7. The preparation method of the aluminum alloy thin plate comprises the following steps: (1) according to the aluminum alloy component ratio, the aluminum alloy raw material is smelted and cast to obtain a cast alloy ingot; (2) the ingot is directly hot-rolled and deformed without cooling after homogenization heat treatment, then immediately coiled to obtain a hot-rolled strip coil, which is cooled to room temperature and subjected to self-annealing treatment; (3) the hot-rolled strip coil is directly cold-rolled and deformed to obtain a cold-rolled plate strip without intermediate annealing treatment; (4) the plate strip is subjected to solid solution quenching and pre-aging treatment to obtain a T4P thin plate. The invention forms a second phase with a suitable size and refines the grains through reasonable preparation method optimization, which significantly improves the forming performance of the thin plate and shortens the preparation and processing steps. By optimizing 6xxx series components for automobile body panels, the optimal microstructure mode is obtained and the forming performance of the sheet is improved. In addition, the preparation processing procedures are omitted, production time is saved, production costs are reduced, and carbon emissions are reduced.

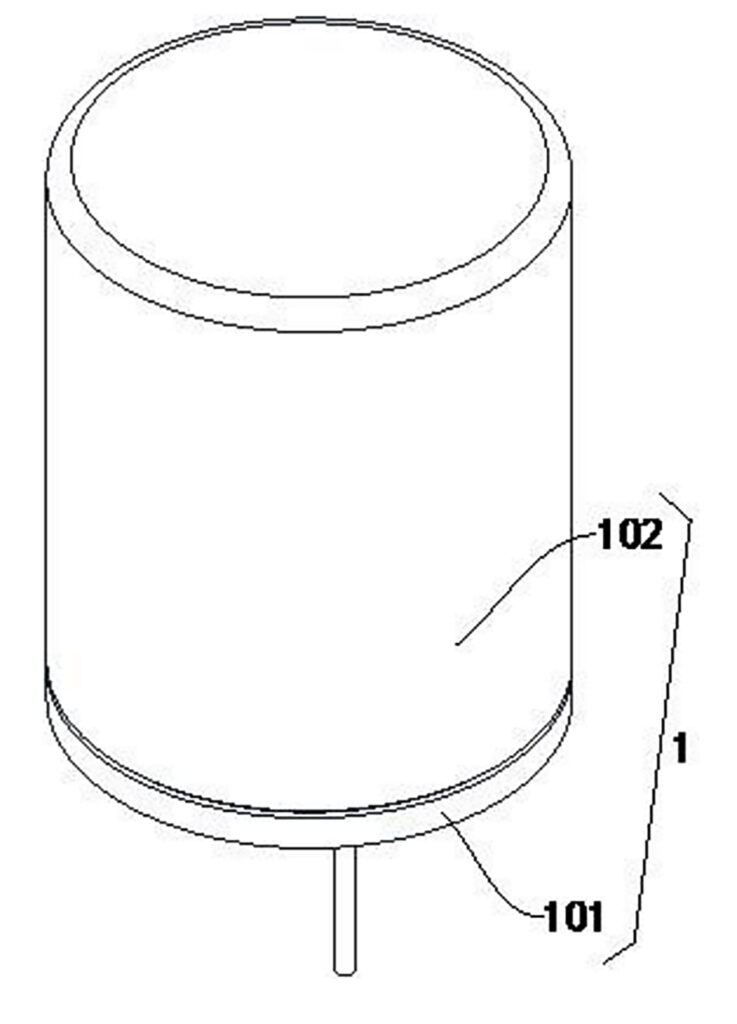

CN119008251B — Flame-retardant aluminum electrolytic capacitors — Nantong Tongrong Electronic Co., Ltd. (China) — The flame-retardant aluminum electrolytic capacitor comprises a sealed shell, in which a first circular plate is fixedly connected, and a first cylinder is coaxially connected to the first circular plate. It actually adopts the design of a sealed shell. When the first cylinder and the first sleeve are separated under the action of the vaporized electrolyte, the electrolyte vapor can enter the sealed shell, driving the driving member to move, and driving the cut-off mechanism and trigger member to move. The first pin is cut off by the cut-off mechanism, and the energy supply of the capacitor is disconnected, so that the capacitor can continue without exploding or burning. Subsequently, multiple air bags are punctured by the trigger member, so that nitrogen and electrolyte vapor are quickly mixed, the oxygen concentration is reduced, and the capacitor core is prevented from burning. Compared with the prior art, it has the advantage of good flame retardant performance and can effectively reduce property losses.

CN222094427U — High-speed forming machine for corrugated aluminum fins — Xinxiang Taige Cold And Warm Technology Co., Ltd. — The utility model discloses a high-speed forming machine for corrugated aluminum fins, and relates to the technical field of aluminum fin production. The automatic feeding device comprises a placement frame, wherein a stamping assembly arranged in the placement frame comprises a placement frame and a placement seat, the placement frame is connected to the inner side wall of the placement frame, a heating rod is arranged in a placement groove formed in the upper surface of the placement frame, a frame cover connected with the upper end of the heating rod is connected to the placement frame, a fixed mold is connected to a placement plate connected with the lower surface of the placement frame, a stamping mold is connected to the lower surface of the placement seat arranged above the placement frame, a through hole is formed in the placement plate, a material returning assembly is arranged on the lower surface of the placement plate, and a placement cabinet contained in the material returning assembly is connected to the lower surface of the placement plate. According to the utility model, the stamping assembly is arranged, the stamping times of the corrugated aluminum fins are reduced, the forming efficiency of the corrugated aluminum fins is improved, and the material returning assembly is arranged, so that the corrugated aluminum fins can be conveniently ejected out, and the downtime of the corrugated aluminum fins during blanking is reduced.