“With the new baking furnace, we will produce even more energy efficiently in the future,” said Dr. Andreas Lützerath, executive board member of Trimet. “This means that the investment in modern technology is paying off twice for Trimet. We are optimizing the quality and performance of our production while also ensuring that our processes are more sustainable.”

Carbon anodes are needed for the production of primary aluminum. In fused-salt electrolysis, liquid aluminum is produced from the chemical reaction of the source material aluminum oxide with carbon by means of electric current. The anodes assume the functions of conductor and reactant in this process.

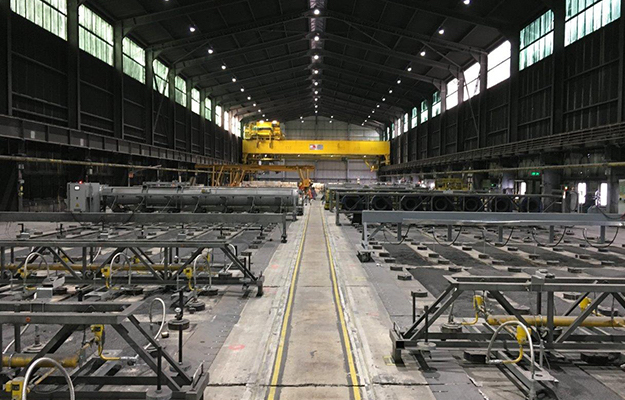

The Hamburg smelter produces anodes for its own metal production, as well as for the Trimet smelter in Essen. About 120,000 tons of carbon anodes are fired annually in the anode plant. Petroleum coke mixed with coal tar pitch is made conductive through the thermal firing process in the furnace. In a process lasting 18 days, the 1.6 m long and nearly 1.2 ton anodes are gradually heated up to 1,100°C in the combustion chambers before being cooled down again.

The new brick-lined ring chamber furnace has 48 chambers. A modern firing system also contributes to the furnace’s greater energy efficiency, with a gas burner that provides more efficient use of energy while simultaneously producing less emissions. In addition, the furnace integrates optimized materials: the bricks used for the furnace walls are easier to heat, so that considerably less energy is required.

Meticulous planning was required for the installation of the new furnace, as the work had to be performed while the plant was still in operation. Around 9,000 tons — totaling more than 1.5 million bricks — were used for the new anode baking furnace, including 34 different brick types. Many of these bricks were individually manufactured and fitted into their specific place. The furnace engineers and more than 100 bricklayers had to coordinate their work with the system’s ongoing firing process.

“The new construction of an anode baking furnace during ongoing operation was a technical and logistical challenge that the team mastered with flying colors in record time,” noted Dr. Jörg Prepeneit, Trimet plant manager in Hamburg. “We can all be proud of the smooth outcome of the project in just ten weeks. Now we can fully concentrate on production again.”