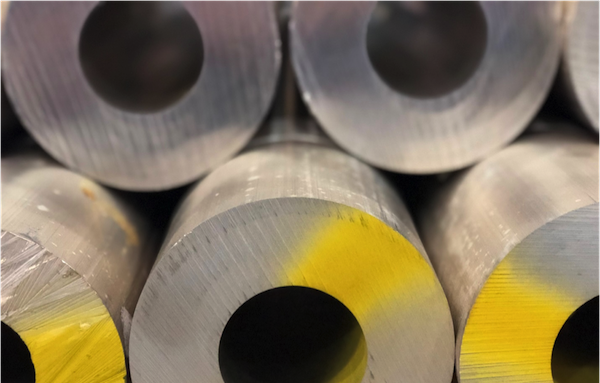

Terves, a subsidiary of PMT Group, is expanding its operation in Euclid, OH. The project includes the addition of 30,00 sq ft to expand production of extruded dissolvable magnesium products. The expansion includes the installation of a vertical direct chill casting system for magnesium alloy billet, which will be the first such system to be installed in North America in this century.

With this installation, Terves will be entering the lightweighting market by supplying magnesium extrusions and castings to automotive, aerospace, defense, and other companies that care about sustainability and have ambitious carbon neutrality goals. Magnesium is the lightest structural material and implementing sustainable lightweight materials and addressing design concepts in a circular economy is one of the most important issues facing OEMs today.

Terves is the only fully integrated wrought magnesium producer in North America, primarily producing dissolvable magnesium alloys for the oil and gas market in North America, South America, Europe, and Asia. Dissolvable alloys are essentially materials that have been formulated to provide high corrosion rates in a controlled manner.

The company’s first success in this area was the development of the TervAlloy series, which was initially designed for the U.S. Department of Defense. These alloys have since been reconfigured and customized into specifically designed reactive materials used for making frac balls, plugs, slips, seals, and several other components used in oil and gas well construction.

Terves broke ground on the expansion of its magnesium extrusion facility on August 18, 2022. The expansion is expected to be completed in 2022.