Vulcan Aluminum Mill installed a new twin-belt continuous casting machine at its facility in Foley, Alabama. The new machine will increase the company’s capacity and efficiency while also improving surface quality.

Founded in 1935, Vulcan Inc. began as a small sign manufacturer in Birmingham, Alabama. Since then, the employee-owned company has grown and now operates a 32-acre manufacturing campus in Foley. The site includes several operations, including the aluminum casting and rolling plant, as well as sheet stamping and sign manufacture.

Vulcan Aluminum Mill produces the aluminum sheet and coil that are used by its sister operations at the manufacturing campus to produce sign blanks and signs for the traffic industry. Vulcan also supplies finished coils of AA5052 and AA5754 alloy sheet to the broader semi-fabricated aluminum sheet market.

Over the years, Vulcan has made a number of investments in its rolling operations. In 2012, the company completed the installation of a new melting furnace, a rebuild of the old melting furnace (known as “Ole Betsy”), and upgrades to its rolling mill.

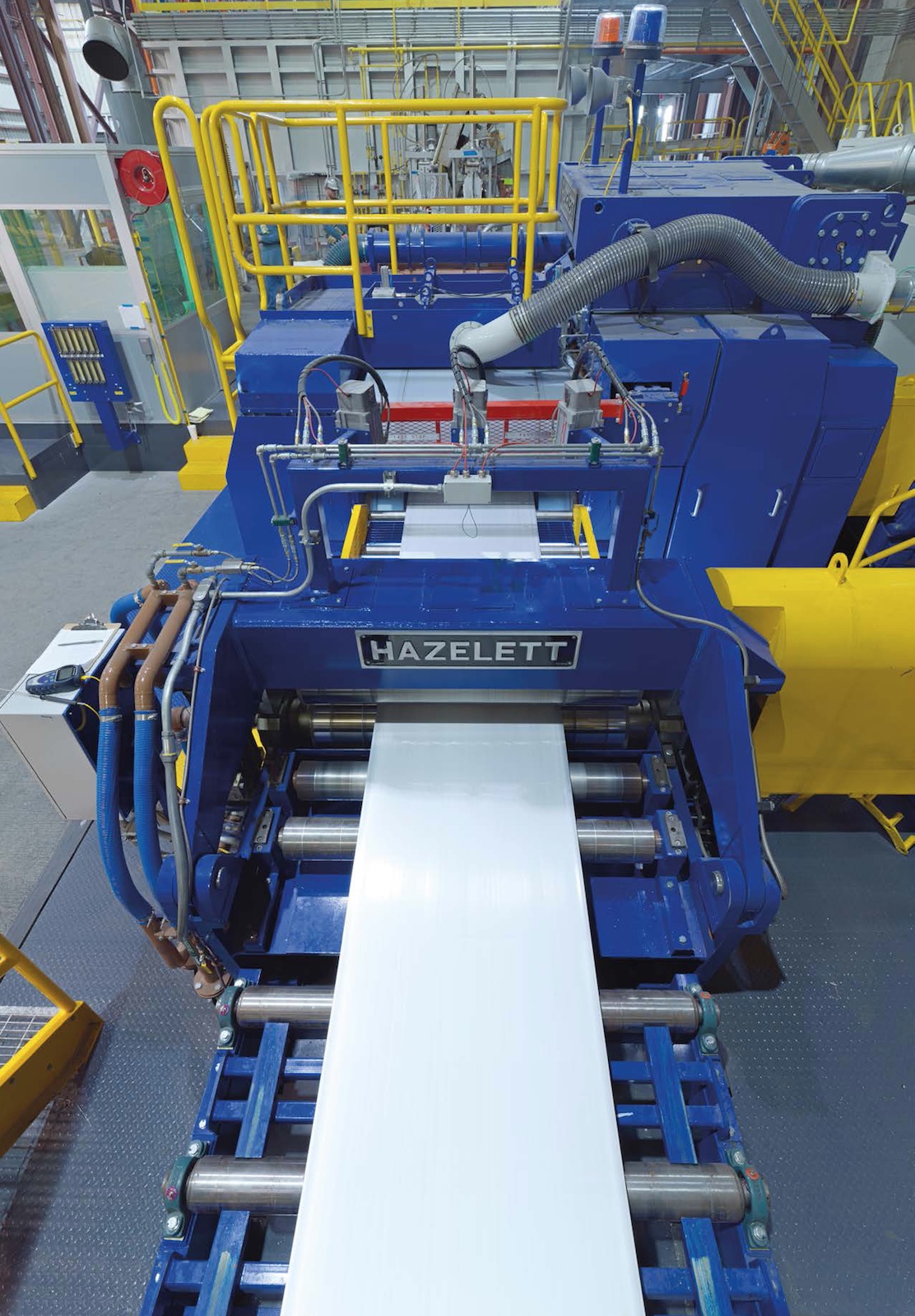

However, Vulcan had been operating the same Hazelett continuous strip casting machine for 35 years. During this time, the company made many improvements to its casting machine in order to support its aluminum sheet business — but in 2021, Vulcan decided it was time to invest in a new continuous casting machine.

The old strip casting machine was replaced with a new AS1300-model, twin-belt continuous casting machine, also supplied by Hazelett (now part of the EBNER Group). Installed in early 2022, the new casting machine is able to produce aluminum strip up to 52 inches (1,320 mm) wide at a rate of over 33 tonnes/hour.

With the installation of the new strip casting machine, Vulcan is able to offer its customers high-quality low-CO2 aluminum sheet in AA1xxx, AA3xxx, AA5xxx, AA6xxx, and AA8xxx series alloys. This enables them to serve a variety of markets, including foil stock, fin stock, building sheet, truck trailer sheet, inner and structural auto-body sheet, and deep drawn sheet, as well as strip for containers formed by impact extrusion.