Golden Aluminum Inc. achieved commercial start-up of a new continuous aluminum strip caster at its Fort Lupton facility in Colorado. Collaboratively developed by Golden Aluminum and SMS group, the Nexcast® machine is the centerpiece of a compact, fully integrated continuous production line that transforms molten metal directly into 36-inch-wide hot-rolled coils for subsequent cold rolling and coating. This next-generation strip caster facilitates the cost-effective production of aluminum sheet with a high scrap content, enabling the company to deliver a wide-ranging portfolio of sustainable products tailored to the packaging, automotive, and construction sectors.

“Bringing Nexcast online marks a major step forward for Golden Aluminum and demonstrates the strength of our collaboration with SMS group,” said Jeff Frim, CEO of Golden Aluminum. “This evolutionary technology not only expands our capabilities, it also improves efficiency and sustainability, delivering clear benefits to our customers across multiple end markets.”

This article highlights Golden Aluminum’s 40-plus-year experience providing continuous-cast aluminum into mainstream markets and explores continuous casting, pointing to its value and addressing misconceptions. It also presents the development of the Nexcast blockcasting technology, which Golden believes provides a transformational opportunity for the flat rolled aluminum sector.

Company Profile

Golden Aluminum was commissioned in Fort Lupton in 1983 under the umbrella of the Adolph Coors Brewing Company. The plant was founded on the risky premise that aluminum beverage cans could be advantageously recycled through a unique continuous blockcaster developed by Lauener Engineering AG in collaboration with Alusuisse. In 1987, Golden Aluminum further committed to blockcasting technology by acquiring Lauener.

The blockcaster installed in Fort Lupton was a narrow prototype (33 inches wide)—one of the few that were ever built. A wide version was installed in another Coors plant in San Antonio, TX, in 1992. However, a series of acquisitions and divestitures through the 1990s resulted in Alcoa acquiring the San Antonio facility (now Arconic), with the blockcaster being decommissioned and replaced by a different system in 2005-2006. More recently, the San Antonio plant has been idled completely.

Golden Aluminum and its Fort Lupton facility were acquired by the current ownership group in 2004. The company continued operating the Lauener blockcaster with great success by developing and carefully tuning processes to serve any niche market for its narrow coils. Golden is now a time-tested supplier of both colored and bare beverage tab stock, as well as stock for food can body and ends, infant formula containers, automotive and EV battery components, beverage closures, and many others.

Even though narrow and smaller-scale compared to other mills, Golden has remained competitive based on the advantages of continuous casting (with its lower energy usage, faster throughput, and lower inventory) and the company’s early adoption of end-of-life (EOL) scrap recycling. The company’s recycling DNA, rooted in Coors’ closed-loop philosophy, drives continuous product development aimed at maximizing EOL scrap use. Some of the company’s product innovations already utilze up to 85% UBC scrap.

For its most demanding products, Golden is the only provider to use continuous casting successfully for their production. This is counter to the common narrative regarding aluminum continuous casting, and the advantage is directly attributable to the blockcasting technology that was originally pioneered by Coors and Lauener.

The Potential of Continuous Casting

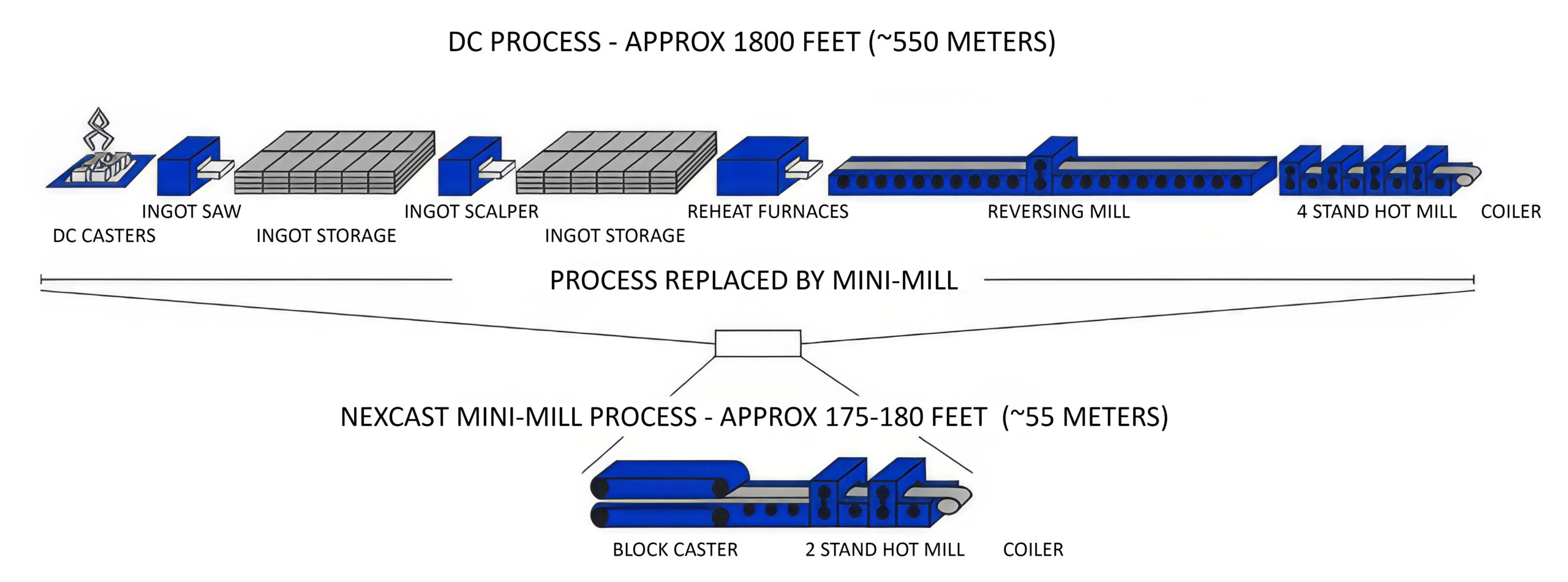

In the aluminum flat rolled products industry, the conventional approach to producing aluminum strip and sheet is to begin with direct chill (DC) casting. With this production method, a rolling ingot (typically 20 inches thick and up) is cast and is then repeatedly processed via scalping and reheating before being reduced in size through a series of massive, reversing, hot rolling passes. The material is then further processed through a multi-stand hot mill until it achieves a strip thickness appropriate for coiling into hot band. Once in hot band form, there are few distinctions in further processing DC versus continuous cast products.

The DC casting method is typically used for high property applications, such as rigid container stock, tabs and closures for beverage cans, battery foils, automotive components, etc. However, the multitude of processing steps makes it costly to install and operate, as well as requiring a high capital expenditure to invest in new capacity.

Another approach is continuous casting, which is currently dominated by the twin-roll and belt methods. Belt casters convert molten metal directly into a 20-25 mm slab between two moving belts. The slab is continuously fed into a hot mill for further reduction into coiled hot band. Belt casters lack stable belt-to-metal contact, limiting precision in mold control and heat removal.

Twin-roll casters rapidly freeze the metal in the small region before a set of two rolls, which is somewhat reduced between the rolling gap to achieve a heavy gauge hot-band of typically 4-8 mm. Typically, twin-roll hot band needs additional cold rolling steps compared to other technologies.

Both of these continuous casting methods vastly reduce the operational steps to achieve hot band, thus providing relative cost advantages compared to the DC casting method. However, the inherent constraints of the belt and twin roll casting methods limit them to common alloys for low property products (or low specification products, often with lower strength and with less alloying elements), such as foil stock, siding, flashing, etc. This includes 1xxx, 3xxx, 8xxx, and lower-magnesium 5xxx series alloys. “Consequently, they are associated with low margins because they require neither advanced equipment nor specialized expertise,” noted Peter von Czarnowski, director of Caster Technology Development, Golden Aluminum.

Blockcasting represents a less known form of continuous casting, with Golden Aluminum being the only company in the world to use the technology. The blockcaster uses a “moving mold” consisting of circulating top-and-bottom copper blocks and side dams to produce a strip of approximately 20 mm thick, which is fed directly into a multi-stand hot mill. Liquid aluminum is thus converted into a continuous strip in a compact space of less than 20 ft. The strip thickness, precise surface contact, and cooling rate control enables Golden Aluminum to process a uniquely broad alloy range with consistent metallurgical structure, resulting in exceptionally tunable properties. As a result, blockcasting merges lower cost saving benefits of continuous casting with the ability to produce strip similar in quality to DC casting for high property applications.

For decades, there has been little economic incentive to shift away from traditional flat rolled production methods (i.e., DC casting for high property products and belt or twin-roll casting for low property products). This is largely thanks to the existing capacities of legacy aluminum plants in the U.S. since WWII, as well as the growing capacities of newer plants in China, Europe, and the Middle East. In fact, between the 1980s and 2000s, U.S. aluminum companies would typically close plants (of any type) rather than make investments in new, transformational technology.

Recently, however, global imbalances and shortages are inspiring new domestic investment in scrap processing and flat rolled production. For example, Aluminum Dynamics started up the first integrated slab casting and rolling complex to be built in more than 40 years at its plant in Columbus, MS, while Novelis is constructing a new integrated rolling complex in Bay Minette, AL.

In this shifting climate toward flat rolled aluminum investment, blockcasting offers an opportunity for further industrial growth at a more economically friendly cost. Although blockcasting is not widely adopted across the industry, the technology has been in operation at Golden Aluminum’s Fort Lupton plant for more than 40 years. Over the last decade, the company has not only delivered quality products profitably to demanding customers, but has also been running trials to demonstrate the range of the technology. In addition to the markets that it regularly serves, Golden has demonstrated the suitability of block-cast material in beverage container body stock, bottle stock, deep drawn closures, automotive structures, aerosol valve bodies, and battery components. In all cases, success was achieved with a limited number of trials and relatively small quantities of trial material.

Redesigning the New Caster

The Lauener blockcaster at Golden Aluminum’s Fort Lupton facility was originally designed as a prototype machine, which has since been run as the company’s main operation. Over the years, the company made a number of improvements to the machine. However, since the original design was based on technology developed in the 1970s with the engineering tools available at the time, the caster was aging out. In order to remain viable, Golden Aluminum needed to replace the old machine with a redesigned blockcaster with updated engineering and technologies.

Golden turned to SMS group in Germany to collaborate on the engineering of the new caster. “SMS was the technology leader in developing strip casting in steel for Nucor, which changed the steel industry,” said Frim. “They are a world-class engineering firm that supplies large equipment to the metals space, so it was a logical choice.”

Thus, the two companies initiated a project to redesign the blockcasting machine. The first use case was providing an updated, seamless replacement for Fort Lupton’s aging blockcaster. During the project, SMS provided all the engineering and design changes to the new caster and manufacturing of the redesigned machine. Golden provided access to the technology, process information, and directional improvements required.

The project started with a deep dive into the existing blockcasting process. Golden provided their knowledge of the technology based on four decades of operation, during which the company gained an inherent understanding of its original design challenges. SMS group performed on-site surveys of the machine and operation to further understand its shortcomings. Next, SMS developed solidification and metal flow models using advanced simulation tools, which were validated with test casts at the plant.

The existing blockcaster had a narrow design (33 inches wide). However, as part of the modernization process, SMS developed and designed an improved casting machine with a 2 m width (~78.7 inches), which is considered to be a more “modern” width for today’s casting and rolling plants. “We focused on maintaining the metallurgical process and considered the valuable input of Golden Aluminum based on their long-term process and operational excellence,” said Michael Schaefer, executive vice president, Flat Products, SMS group. “Prototypes of core components in full sizes, like the cooling block with carrier beam and drive components were manufactured and tested in the SMS workshop to verify the new design and the models.”

Although SMS engineered a 2 m wide machine, the narrow design of the existing blockcaster represented the heart of Golden Aluminum’s business. Therefore, when they placed the order for the new blockcaster to replace their outdated Lauener machine, they specified a narrow design of 36 inches wide for the new Nexcast blockcaster. As a result, the engineering of the new machine was adapted to the narrower width. In parallel with this, the SMS automation team developed state-of-the-art hardware and software solutions.

After engineering was completed, the Nexcast blockcaster was manufactured, assembled, and finally tested in cold and hot conditions in the SMS workshop in Hilchenbach, Germany (Figure 1). “Since it was not possible to test the caster in hot condition with liquid metal, burners were used to hot test the caster,” explained Schaefer. “Any kind of issues observed like excessive wear, process disturbances during test runs, or automation control bugs were tackled by re-engineering and re-testing until both SMS and Golden agreed that the risks imposed on Golden’s running business by replacing their only casting machine would be low enough.”

In November 2024, after a rigorous, year-long application process, Golden received approval for up to $22.3 million in grant funding from the U.S. Department of Energy (DOE). The grant award was centered on Nexcast, the demonstration of operating improvements, and the capabilities of the technology as a demonstrator for the industry. The grant uses a cost sharing reimbursement model, in which the DOE will reimburse Golden for 50% of approved project spending.

“Funding was applied during the final validation phase of detailed engineering, when it became clear that the project was technically mature and set up for success,” said von Czarnowski. “Prior to the application, we had already demonstrated product and alloy capability beyond the existing Golden Aluminum portfolio and outlined its potential impact on the U.S. aluminum industry and circular economy. As a result, we presented verified arguments in terms of engineering maturity, product capability, and clear advantages in material and energy efficiency, which kept the funding risk low for the DOE.”

As engineering and funding were being finalized, Golden Aluminum engaged in a year long process of planning for installation of the new blockcaster at Fort Lupton, which would involve removing the old caster, replacing it with the Nexcast machine, cold and hot commissioning of the line, and finally production. “The preparation phase was extensive,” noted von Czarnowski. “We reviewed the procedures and equipment and identified modifications made over time, capturing the individual operational knowledge accumulated by our team. We also ensured full transparency as part of our cooperation with SMS as the supplier. Finally, after the long prep-period, the old caster removal and Nexcast installation was managed in only seven weeks with exceptional precision and discipline.”

The shutdown for the installation began on June 1, 2025 (Figure 2), with the first hot-rolled aluminum coil achieved on July 5 and full production shortly thereafter in August. “The project itself was like conducting a heart transplant for the company,” explained Frim. “The execution of the project was incredible, completed with zero injuries and on time. It took tremendous courage and grit from the Golden Aluminum team to complete such a tremendous undertaking. A failed project would have put the company’s existence in jeopardy.”

Results

The engineering phase of the Nexcast project provided a number of enhancements to the blockcasting technology, including a redesign of the beam, alignment system, and thermal management system. The redesigned cooling block beams with a new block carrier concept and new machine frame design improve stability and precision of the casting process, guaranteeing smooth melt solidification.

The new blockcaster also features a significantly shorter caster downtime during block changeout. This is thanks to the new block change concept with a plug-and-play design that enables all block adjustments to be made offline, instead of completing them online with the old caster.

In addition, the design includes a higher degree of sensors and automation, including features like automatic compensation of thermal expansion of the blocks and fully automatic block surface cleaning. As a result, the system is able to achieve more reliable casting and less operator intervention. The software implementation was carried out entirely with modern Siemens TIA software using motion control technology. The integrated smart controls optimize key process parameters, making it possible to refine the aluminum’s texture and grain to optimize it for downstream rolling and heat treatment. In addition, the new instrumentation provides a better picture of the process variables, enabling operators to identify quality issues and explore improvement opportunities.

Thanks to the overall concept (including the mechanical design, automation control, and hydraulic system), the redesigned Nexcast line provides improved process stability and equipment reliability, better process control for high quality and product consistency (Figure 3), and higher production efficiency.

Within the first month of operation, the Nexcast line at Fort Lupton had achieved full ramp-up, including the production of multiple AA5xxx grades, such as high-magnesium AA5182. The line has already successfully completed record breaking casting campaigns, with seamless ad-hoc alloy changeovers, highlighting the reliability and flexibility of the system.

“Productivity of Nexcast is outstanding, with a doubling of our average cast lengths,” said Frim. “Caster production rates are up about 15% and climbing, and cold mill rates are also up over 15%. Quality has improved tremendously with a significant reduction in edge and surface cracking, allowing for improved process yields and throughput downstream of the caster.”

Further Growth

Blockcasting has long been the core of Golden Aluminum’s business, proving the value of this novel technology. The redesign of the entire system has expanded the quality and reliability of the new blockcaster, setting the company up for further growth. “At Fort Lupton, Nexcast will support increasing finished rolled product plant output by 25% by 2028, with ample additional casting capacity to supply hot band and trial material for market development,” said Frim.

Over the next few years, the Nexcast technology will continue to be optimized, including the design of a 2 m wide machine. The aim is to expand the alloy offerings possible with blockcasting and explore new applications to support the industry’s shift toward eco-friendly, future-oriented aluminum products.

Compared with conventional DC casting, Nexcast shortens process sequences and reduces energy consumption, while lowering the carbon footprint by eliminating ingot casting and other intermediate steps. The compact layout, measuring less than 60 m from melting to coiling, also significantly cuts capital requirements (Figure 4). In addition, the blockcasting technology provides the ability to cast high-alloy and heat-treatable aluminum specialty grades that are typically not feasible for other continuous casters, as well as the possibility of processing increased amounts of scrap compared to DC casting thanks to its inherent rapid solidification. It also provides lower energy input, lower water consumption, and better inventory management than DC casting.

Golden Aluminum believes that this technology offers a huge value to the flat rolled aluminum industry as a whole, providing an advantageous alternative to DC casting. Therefore, the company formed a joint development agreement with SMS group to collectively develop and commercially market Nexcast and the Nexcast Mini-Mill, which combines the blockcaster with a multi-stand hot-mill. Under this agreement, SMS group will provide the engineering and technology expertise and will supply the equipment, while Golden will provide operations knowledge, product and end-market understanding and inroads, and process and production know-how.

“Nexcast is the only continuous strip casting technology capable of producing more sophisticated and technically challenging alloys, such as 5182, used in can sheet and automotive applications,” said Frim. “It will allow for incremental capacity additions to either current mills or new greenfield locations, and its versatile casting capabilities allow the new user a wide variety of product options. If the aluminum industry’s future is to be circular, efficient, and local, then this technology may well prove to be its transformational linchpin.”

Editor’s Note: This article first appeared in the December 2025 issue of Light Metal Age. To receive the current issue, please subscribe.