By Craig Werner, Werner Extrusion Solutions, LLC

On November 4th and 5th, Aluminum Extruders Council (AEC) members who have signed up early for the limited spots available will have the chance to attend the Process Optimization Workshop (POW).

The planning and preparation for this event took the dedication of AEC volunteers and staff over a year; this effort and relentless focus will provide attendees with a not-to-be-missed opportunity to obtain a wonderful understanding of our industry, our material, our process and the equipment that makes it possible, all from some of the most renowned experts in our field.

The workshop will be a mix of lectures, problem solving opportunities, and panel discussions. Equipment supplier discussions and tabletop displays will be available during breaks and food functions, providing the type of operational networking simply unavailable elsewhere.

We have gathered some of the best minds in the extrusion business from extruders to suppliers of metal and equipment to provide attendees with the chance to learn optimization techniques directly applicable to their operations.

The POW will not be covering the same materials as the AEC Die Clinics or Press Maintenance Workshops, because these are already available for members and because doing so would add at least 2 or 3 days to the schedule.

Here’s an inkling of the mix of presentations and panel discussions what’s in store for those who sign up before the workshop spaces sell out:

- Process and Market Overview – what is important to know about each

- Standards Overview of the technical standards that dictate our process and equipment requirements

- An overview of tolerancing systems and issues

- Market specific requirements

- A focus on Extrusion alloys, most specifically the 6xxx series

- A metallurgical explanation of the alloys which will help the attendees to fully understand why various process and equipment choices are so critical

- An overview of Casting and Homogenization so that the attendees understand their billets and logs

- An in-depth discussion of the thermo-mechanical processing that the material goes through in the various heating, extruding, quenching, etc… steps

- Artificial aging

- Upset and Metal Flow during extrusion

- Safety Practices and “cautionary tales”

- Log Equipment Panel discussion with suppliers

- Die Heating

- Extrusion Press Panel discussion with suppliers

- Lubrication needs of the extrusion process

- Extrusion temperature measurement and in process checks

- Handling System Panel discussion with suppliers

- Aging and extrusion inspection/packaging Panel Discussion with suppliers

- A review: What’s the point? How the material, process and equipment yield metallurgical performance and shape control

- Operational optimizations possible by pulling all that has been learned in the prior 2 days into practice. How and what to do.

The AEC Process Optimization Workshop differs from other offerings in its focus upon aspects of the material, processes and equipment directly applicable to operations and production. The POW brings all of the necessary learning (save for Die Clinic and Press Maintenance Workshop topics) into one place at one time for a comprehensive understanding, providing an “all in one place” opportunity of the operational aspects of extrusion.

As there is far more material than two day POW can cover, two webinars will be held for registered attendees only. A pre-workshop webinar will provide information on the market and high level material overview and a post-workshop webinar will cover the critical data systems and resulting optimization opportunities this data presents.

Craig R. Werner has extensive knowledge in the aluminum extrusion industry, having held industrial and design engineering positions with Werner Co. and Alcoa. Over his 25 year career, he progressed from project manager to plant manager, general manager, and director of manufacturing for Werner Co. Craig has maintained extensive ties with the Aluminum Extruders Council (AEC), participating in all the ETs, many international technology tours, and leading the organization’s Technical Services Committee. His present venture, Werner Extrusion Solutions (WES), LLC, utilizes his knowledge and experience in metallurgy, modeling, operations, and tooling to provide consulting services to extruders. WES works with extruders of all sizes and capabilities, helping them to optimize their operations and providing key decision support as they make critical equipment selection and operational/process decisions. Craig Werner can be reached via email at: craig.werner@wernerextrusion.com.

Craig R. Werner has extensive knowledge in the aluminum extrusion industry, having held industrial and design engineering positions with Werner Co. and Alcoa. Over his 25 year career, he progressed from project manager to plant manager, general manager, and director of manufacturing for Werner Co. Craig has maintained extensive ties with the Aluminum Extruders Council (AEC), participating in all the ETs, many international technology tours, and leading the organization’s Technical Services Committee. His present venture, Werner Extrusion Solutions (WES), LLC, utilizes his knowledge and experience in metallurgy, modeling, operations, and tooling to provide consulting services to extruders. WES works with extruders of all sizes and capabilities, helping them to optimize their operations and providing key decision support as they make critical equipment selection and operational/process decisions. Craig Werner can be reached via email at: craig.werner@wernerextrusion.com.

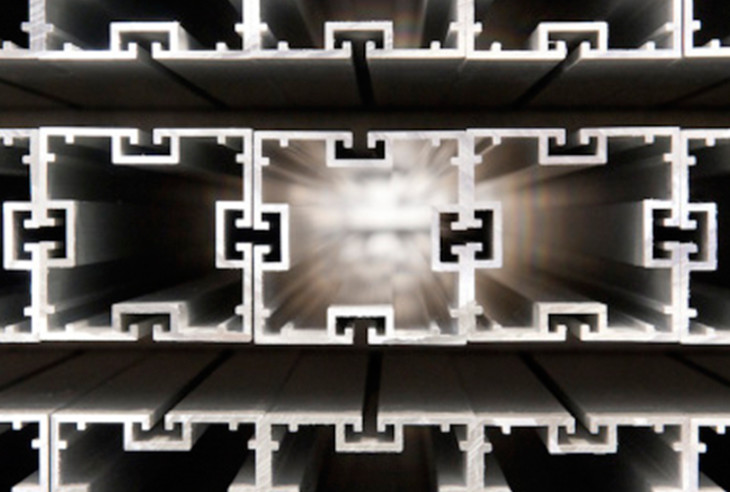

(Featured extrusion photo courtesy of Futura Industries.)