Reliefed Technologies, headquartered in Gothenburg, Sweden, will receive a €2.5 million grant and €3.5 million in equity from the European Innovation Council (EIC). The company was selected out of 1,000 applicants.

“This financial support is a very welcome contribution and confirms the strength of our business plan and the competency of our team,” said Mikael Eklund, CEO of Reliefed Technologies. “This money will speed up the implementation of z.trusion® in both automotive and other key industries and reduce the world’s CO2e emissions at an even faster rate.”

Reliefed will use the funding to support the development and commercialization efforts of its z.trusion® manufacturing technology. In addition, it will fund the establishment of the company’s first z.trusion Tech Center, thereby accelerating the adoption of the technology in the battery industry.

The Technology

With the growth of the electric vehicle market, it is expected that the battery industry will experience booming growth over the coming years. As a result, manufacturers are racing to design the best performing, commercially viable, yet regulatory approved battery packs.

But designing the next generation of battery packs is not easy. They must be light, strong, thermally regulated, recyclable, and cheap — a challenge that is attracting some of the smartest minds in the world. However, there are specific hurdles and limiting factors that all engineers facing this task need to consider, no matter how intelligent of their design — namely, the efficiency, physical constraints, and associated cost of existing manufacturing technologies.

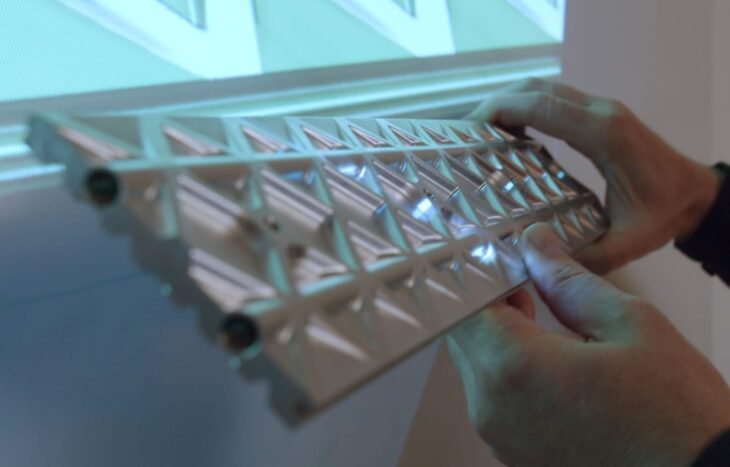

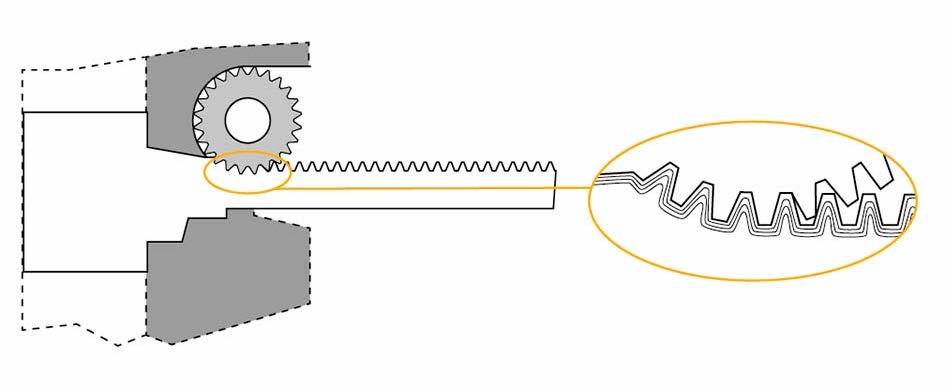

Z.trusion is a patented technology that was developed to address many of these challenges. This technology enables manufacturers to imprint 3D designs on extruded aluminum profiles. Essentially, z.trusion dies are installed on a standard extrusion press. After the profile is extruded, the specialized dies (which rotate on the third axis) imprint three dimensional details on the aluminum profile.

By upgrading the extrusion process — one of the most widespread adopted manufacturing technologies in the world — z.trusion is able to provide cost-efficient manufacturing of advanced three dimensional, lightweight optimized profiles. As such, the technology brings a unique opportunity for cost sensitive industries, such as automotive and construction, enabling designers, engineers, and manufacturers to rethink their product range and save large amounts of material, energy, and CO2 emissions in the process.

In order to highlight the possibilities that z.trusion can bring to the automotive industry, Reliefed Technologies developed a tab-cooled battery solution and tested it alongside the Research Institute of Sweden (RISE) in 2022. The tests of this tab-cooled battery showed several notable results, including a lightweight and strong design that is fully integratable with vehicle structures and 6C charging from 20-80% SOC (state of charge). In addition, the battery system showed 47% less temperature rise compared to Tesla’s battery solution in simulations at 6C charging, increased the lifetime of the battery by 2-3 times, and had a lower environmental impact.

The ability to achieve 6C charging and other benefits of the design have generated a substantial market interest, showing what a critical technology z.trusion could be for the competitiveness of one of Europe’s most vital industries. Part of the funding from the EIC will be used to realize and commercialize the tab-cooled battery solution in collaboration with customers and key partners such as Fraunhofer IWU, Henkel, and Jönköpings Universitet.

Technology Center

The funding from the EIC will enable Reliefed Technologies to build its z.trusion Tech Center, which will be furnished with extrusion lines that have been upgraded with z.trusion for the production of profiles comprised of aluminum and other materials. The Tech Center will be the first of its kind in the world. It will be instrumental in enabling the rapid prototyping and technical validation required to realize future battery designs and make z.trusion ready for the automotive industry.