Winners of the 2017 International Aluminum Extrusion Student Design Competition were announced by the Aluminum Extruders Council. The top three winners of the competition realized many of the advantages that aluminum extrusions have to offer with their designs for an improved bike rack, electrical fencing, and stand for transporting medical equipment. Industrial lighting figured large in two other categories of the competition: the Bonnell Aluminum LED Light Design Challenge and honorable mention awards. The former won for a design, which serves as a bench, streetlight with solar powered tracking system, and a WiFi station and the latter for a “smart” signal light. Bonnell Aluminum sponsored the competition. Scholarships totaling $8,500.00 were awarded to the clever students.

First Place, with a $3,000 scholarship, was awarded to Garen Gibbs, a sophomore studying industrial design at Purdue University in West Lafayette, Indiana, for his “Axial Bike Cargo Rack” with adaptable storage and integrated LED signal lights. The judges liked the expandable configuration, incorporated joining mechanism, and hinged design. “My design uses the aluminum extrusion process to create a bike rack with a low process cost … [the] lightweight and reflective qualities [of aluminum] … enhance cyclists’ visibility and make commuting with excess cargo much more simple,” noted Gibbs. The sides of the rack fold inward to grasp cargo of varying sizes and nest neatly into the main body when closed. The remote-controlled LED lights with turn signal indicators provide optimum visibility for the rider.

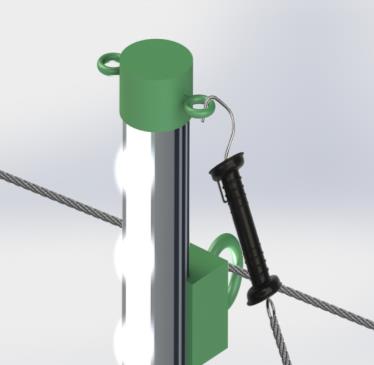

Second Place, with a $2,000 scholarship, was awarded to Lauren Hughes, a senior studying product design at Aston University in Birmingham, UK, for her design, “Equi-Light” electric fence guiding poles. The lighted electrical fence provides assistance on horse farms when horses are guided to grazing paddocks in dark conditions. “The Equi-Light electric fence guiding poles uses technology available to take basic electric fencing to the next level,” said Hughes. She notes that, “56% of horse owners have had a ‘close call’ when their horse spooks in the dark. These lights allow for horse owners to guide themselves and horses safely in dark conditions, lighting the floor in front of them and providing a safe ‘runway’ without the risk of accidentally walking [into] electric fence wire.”

Third place, with a $1,000 scholarship, was presented to Jesse Palma, a sophomore studying industrial design at Purdue University for the “Medpole” medical equipment stand. “Medpole is an interchangeable medical stand aimed to give nurses customization to transport medical equipment from patient to patient,” noted Palma. The Medpole is designed to accept any small machine or accessory by screwing it on to an attachment that slides into the slot. The design also accommodates an IV pole.

The designs were judged by aluminum extrusion industry professionals, including David Asher, Process Optimization manager at Bonnell Aluminum; Todd Boyer, director of New Business Development at Mid-States Aluminum Corp. in Fond du Lac, Wisconsin; William (Bill) Rogers, corporate director, Metallurgy and Process Technology at Arconic, headquartered in Pittsburgh, Pennsylvania; and Craig Werner, VP Extrusion Technology at Kaiser Aluminum headquartered in Foothills Ranch, California.

More than 33 entries from 15 schools and universities around the world were received. To view the winning entries from the 2017 International Aluminum Extrusion Student Design Competition, as well as the winning entries from past student and professional Design Competitions, visit: www.ETFdesign.org.