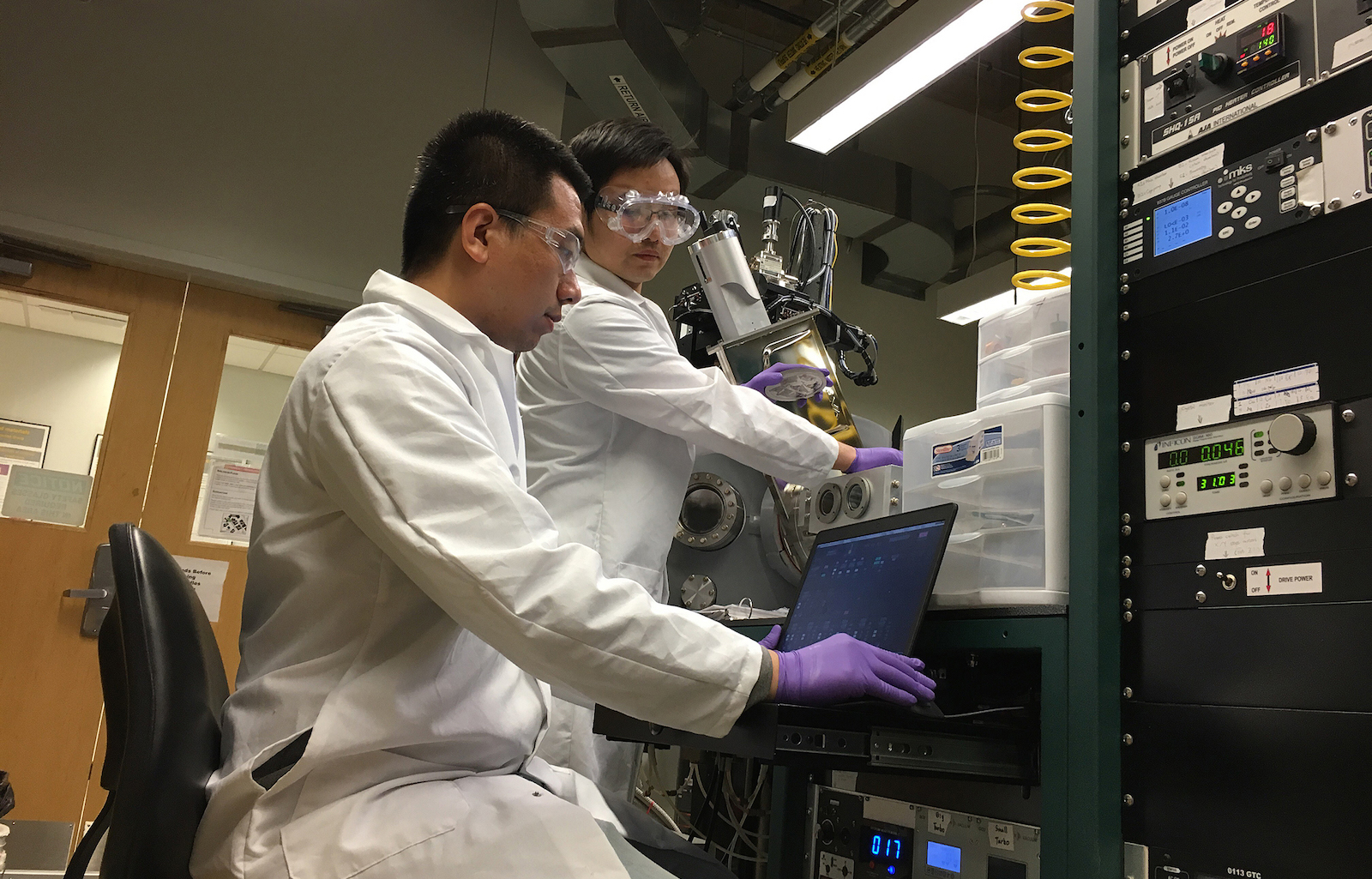

Researchers at Purdue University developed a high-strength aluminum alloy and coatings. Xinghang Zhang, a professor in Purdue’s School of Materials Engineering who led the team of researchers, noted that there is increasing demand for such materials because of their advantages for automakers and aerospace industries.

“We have created a very durable and lightweight aluminum alloy that is just as strong as, and possibly stronger than, stainless steel,” Zhang said. “Our aluminum alloy is lightweight and provides flexibility that stainless steel does not in many applications.”

Yifan Zhang, a graduate student in materials engineering and another member of the Purdue research team, said the aluminum alloy they created could be used for making wear- and corrosion-resistant automobile parts, such as engines and coatings for optical lenses for specialized telescopes in the aerospace industry.

The researchers created the high strength aluminum alloy by introducing “stacking faults.” A metal’s crystal lattice is made up of a repeating sequence of atomic layers. If one layer is missing, there is said to be a stacking fault. These distortions in the crystal structure of the aluminum can lead to so-called nanotwins and complex stacking faults, such as a 9R phase.

“The 9R type of stacking fault is usually rare in aluminum,” said Qiang Li, a doctoral student and member of the team. “We introduce both twin boundaries and 9R phase within nanograins to the lightweight Al alloys that are both strong and highly deformable under stresses. Besides coating applications, we are also looking into scale-up potentials of bulk high-strength Al alloys.”

The team also created a way to develop the superstrong alloy coatings by introducing iron or titanium atoms into aluminum’s crystal structure. The resulting “nanotwinned” aluminum-iron alloy coatings proved to be one of the strongest aluminum alloys ever created, comparable to high-strength steels. The findings were published recently in Advanced Materials and Scripta Materialia.

The Purdue Office of Technology Commercialization helped secure a patent for the technology, which is available for licensing.