Novelis Inc. introduced Generation II of its lightweight battery enclosure solution for the rapidly growing electric vehicle (EV) market. The advanced aluminum-sheet-intensive design maximizes weight reduction, reduces costs, and delivers higher pack energy density compared to traditional EV battery enclosures made from steel or aluminum extrusions.

“The second-generation battery enclosure is the direct result of listening to the feedback from the market and working in close collaboration with our partners and customers,” said Pierre Labat, senior vice president and chief strategy & sustainability officer at Novelis. “It is a benchmark in how the use of aluminum is yielding innovative, more sustainable solutions for the global automotive market and EV makers. Our new EV battery enclosure further positions aluminum as the industry standard for better-performing, longer-range and more competitive cost-to-weight electric vehicles.”

Development

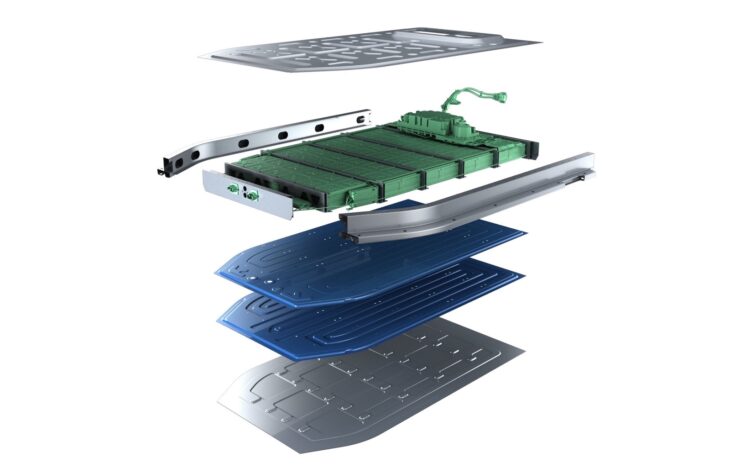

Novelis made its first foray into designing a sheet-intensive aluminum battery enclosure in 2019, when the company introduced its Generation I concept. Since then, the company has worked with industry partners and automotive engineers to optimize the design and introduce production-feasible innovations, including high-strength aluminum roll forming, advanced cell-to-pack (CTP) modular architecture and a structurally integrated thermal management bottom plate.

According to Novelis, these innovations, combined with the company’s advanced material technology, result in a best-in-class frame mass efficiency of below 1.0 kg/Kwh and a mass reduction improvement of more than 20% versus the benchmark aluminum production enclosure from a leading European electric SUV manufacturer. The improved CTP package efficiency and structural performance also delivers a 30% improvement in energy density versus the benchmark.

Using high-performing Novelis Advanz™ s650 alloy in roll-formed frame sections, the new EV battery enclosure is 50% lighter than traditional steel enclosures and more cost-effective than extrusions in most cases. As a result, it can be easily adapted to accommodate specific OEM vehicle designs. By utilizing the company’s highly formable alloys, the enclosure provides automakers the ability to achieve deep drawn, complex shapes.

In addition to the detailed design solutions, Novelis states that it has developed first-of-its-kind engineering methodology and design guidelines to specify lightweight aluminum for top cover applications, while referencing many of the most stringent global thermal runaway resistance requirements. The simulation-derived guidelines will allow companies to quickly determine the optimal specifications to achieve their unique vehicle objectives, replacing steel with aluminum in a top cover application.

The new enclosure is developed and designed specifically for automakers to use advanced, CTP battery packaging architecture, which is 15% to 20% more compact than traditional cell configurations and requires fewer parts to build. CTP enclosure architecture is lighter weight, lower cost and increases volumetric energy density.

The second-generation solution also demonstrates the inherent benefits of aluminum over other materials for EV battery enclosures. Aluminum is more corrosion-resistant, infinitely recyclable, and has superior thermal conductivity properties. Those attributes promote more efficient battery use for longer range.