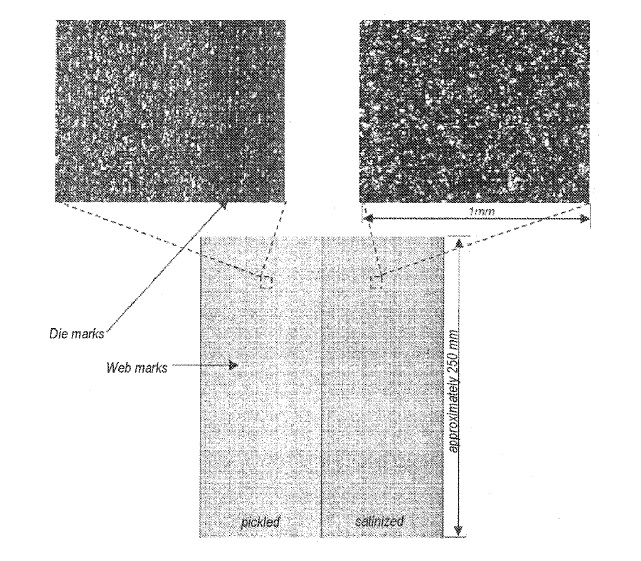

US10335924 — METHOD AND BLASTING MEANS FOR PRODUCING A SATINIZED FINISH ON AN ALUMINUM SUBSTRATE — Vulkan Inox GmbH (Germany) — A method and a blasting material for producing a satinized surface on an aluminum substrate is provided. There is proposed a method for producing a satinized surface on an aluminum substrate, including the steps of: providing an aluminum substrate and treating by blasting with a blasting material the surface regions of the aluminum substrate provided that are to be satinized; wherein there is used as the blasting material a mixture of angular and spherical particles having a grain diameter D90 of ≤0.3 mm, deoxidizing the blasted substrate surface, anodizing the surface regions treated by blasting and sealing them. The substrate surface to be anodized may be subjected to a polishing treatment before anodizing.

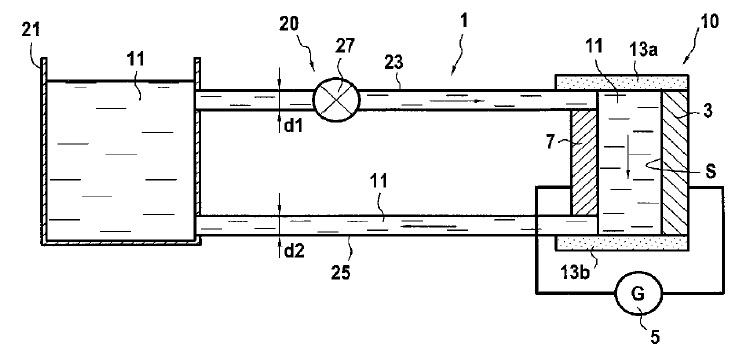

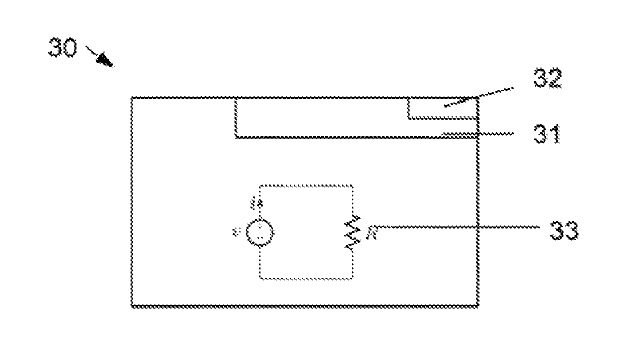

US10329685 — DEVICE INTENDED FOR IMPLEMENTING AN ANODIZATION TREATMENT AND ANODIZATION TREATMENT — Safran Helicopter Engines and Safran Landing Systems (France) — A devicea for performing anodizing treatment on an aluminum, magnesium, or titanium part, the device including a treatment chamber including a part for anodizing together with a counter-electrode situated facing the part to be treated, the part to be treated constituting a first wall of the treatment chamber; a generator, a first terminal of the generator being electrically connected to the part to be treated and a second terminal of the generator being electrically connected to the counter-electrode; and a system for storing and circulating an electrolyte, the system including a storage vessel, different from the treatment chamber, for containing the electrolyte; and a circuit for circulating the electrolyte in order to enable the electrolyte to flow between the storage vessel and the treatment chamber.

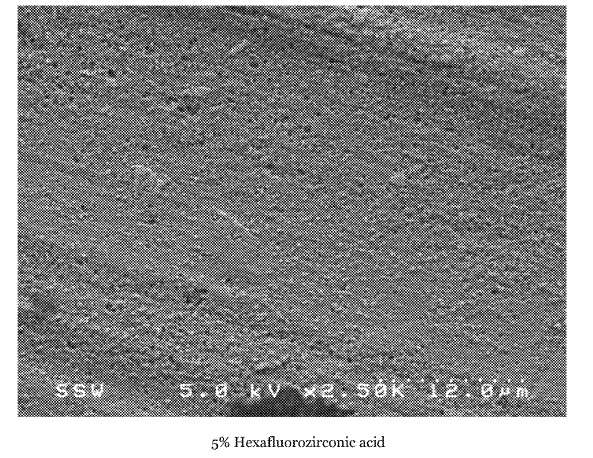

US10329674 — FLUORINATED ACID COMPOUNDS, COMPOSITIONS AND METHODS OF USE — Vitech International, Inc. (USA) and Win Chemicals, Ltd. (Canada) — Novel acid-based chemistries that can be used in various cleaning, de-scaling, rust-removal, brightening, etching and other similar applications, including, but not limited to, those based upon hexafluorozirconic acid and other additives, such as urea in some applications, which are effective for a wide range of applications, while avoiding the health, safety and environmental issues that are often associated with the use of hydrochloric acid and other toxic chemistries.

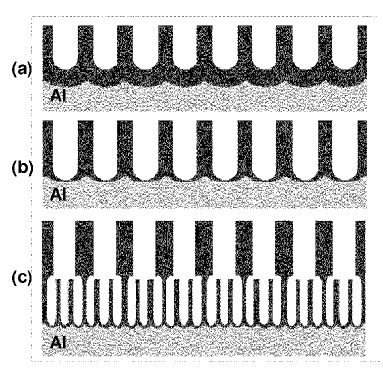

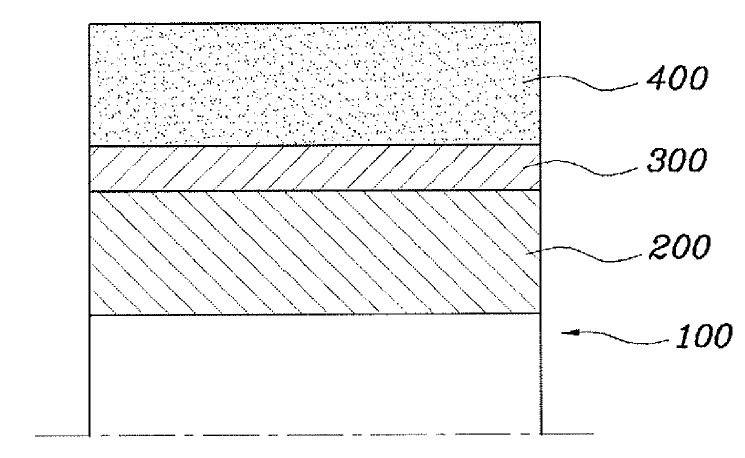

US10309029 — METHOD FOR FORMING A MULTI-LAYER ANODIC COATING — Technological University Dublin (Ireland) — A method for producing a multi-layer anodic coating on a metal such as an aluminum workpiece is described. The method comprises the steps of (i) placing the metal in a first electrolytic solution and applying a current to form a first anodic layer having a barrier region; (ii) reducing the applied current to cause a reduction in thickness of the barrier region; and (iii) placing the metal in a second electrolytic solution and applying a current to form a second anodic layer.

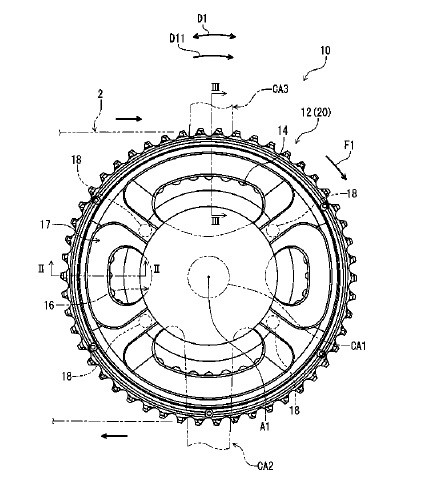

US10302184 — BICYCLE COMPONENT, BICYCLE SPROCKET, AND BICYCLE COMPOSITE SPROCKET — Shimano Inc. (Japan) — A bicycle component comprises a base member and a first alumite layer (anodized). The base member is made of an aluminum alloy. The first alumite layer is provided on the base member. The first alumite layer has a thickness that is equal to or larger than 1.0 μm.

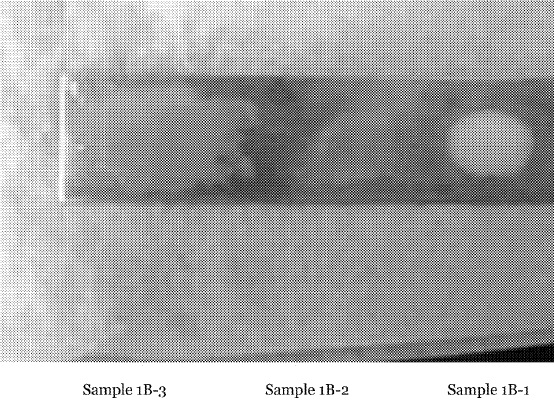

US10301706 — ALUMINUM ALLOY SHEET THAT EXHIBITS EXCELLENT SURFACE QUALITY AFTER ANODIZING AND METHOD FOR PRODUCING THE SAME — Sumitomo Light Metal Industries, Ltd. –(Japan) — An aluminum alloy sheet that exhibits excellent surface quality after anodizing, includes a peritectic element (Ti or Cr or both) that undergoes a peritectic reaction with at least aluminum, and requires an anodic oxide coating is characterized in that the concentration of the peritectic element in a solid-solution state that is present in the outermost surface area of the aluminum alloy sheet varies in the widthwise direction of the aluminum alloy sheet in the form of a band having a width of 0.05 mm or less, and the difference in the concentration of the peritectic element between adjacent bands is 0.008 mass % or less. The aluminum alloy sheet additionally comprises one or more elements among 0.3 to 6.0 mass % of Mg, 0.5 mass % or less of Cu, 0.5 mass % or less of Mn, 0.4 mass % or less of Fe, and 0.3 mass % or less of Si, with the balance being Al and unavoidable impurities.

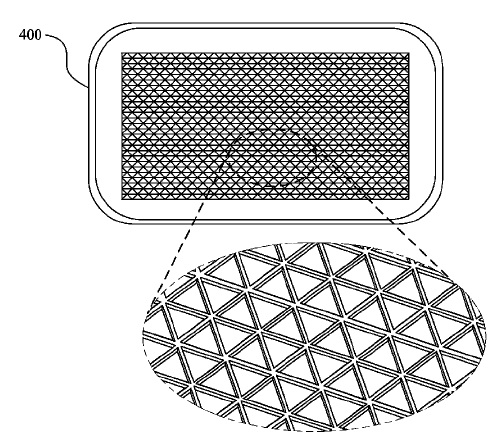

US10295872 — DISPLAY SUBSTRATE, DISPLAY DEVICE AND MANUFACTURING METHOD THE SAME — Boe Technology Group Co., Ltd. and Hefei Xinsheng Optoelectronics Technology Co., Ltd. (China) — A display substrate, display device and manufacturing method the same are provided. The display device includes an ordered porous thin film wherein the ordered porous thin film includes a porous anodic aluminum oxide film or a titanium dioxide nanotube array film; a plurality of sub-pixel regions arranged in a matrix, a plurality of pore passages being disposed in each sub-pixel region, each pore passage having an opening on the surface of the ordered porous thin film; a plurality of quantum dots respectively arranged in at least part of the plurality of pore passages; and a first electrode layer and a second electrode layer respectively arranged on two sides of the ordered porous thin film, the second electrode layer including a plurality of sub-electrodes spaced apart from each other and respectively corresponding to the plurality of sub-pixel regions. The display substrate, display device and their manufacturing method have relatively high color gamut and quantum dots light-emitting efficiency.

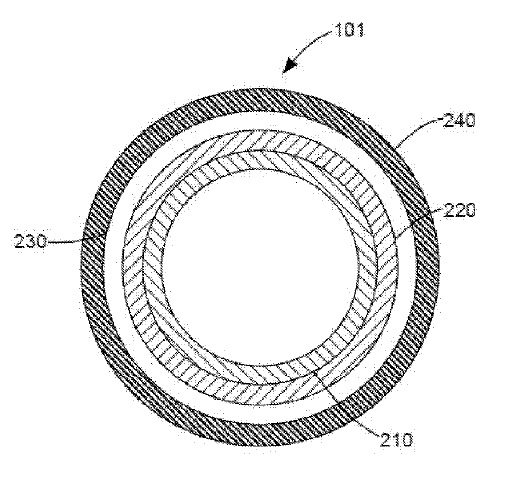

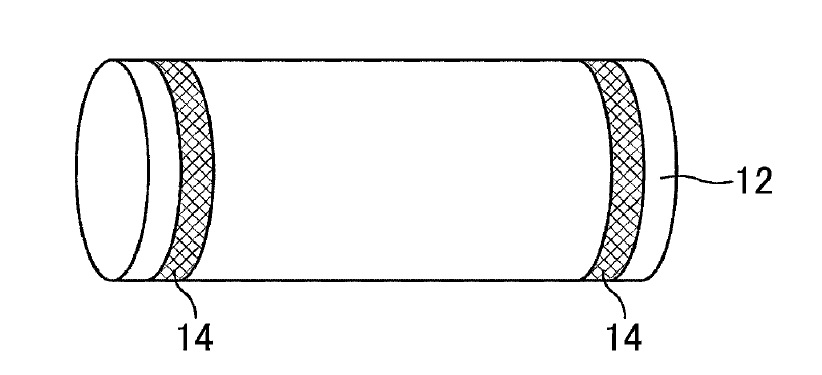

US10289014 — METHOD TO MAKE A PHOTOCONDUCTOR DRUM HAVING AN OVERCOAT USING A DUAL CURING PROCESS — Lexmark International, Inc. (USA) — method of preparing an organic photoconductor drum having a protective overcoat on its outermost surface is provided. In an example embodiment, a photoconductor drum having an electrically conductive substrate such as aluminum, a charge generation layer, a charge transport layer and an outermost protective overcoat layer, from 0.1-10 μm is provided. The photoconductor drum is cured using a two-step process. The first curing step applies either ionizing irradiation, such as with an electron beam or by gamma rays or applies non-ionizing irradiation such as ultraviolet light to the photoconductor drum. A mask is sized and placed over the print area of the initially cured photoconductor drum, thereby exposing the outermost edges of the photoconductor drum. The outer edges of the masked photoconductor drum is then exposed to a second curing step using ultraviolet light irradiation.

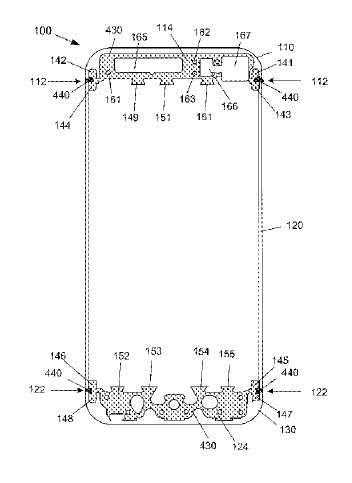

US10285295 — COMPONENTS OF AN ELECTRONIC DEVICE AND METHODS FOR THEIR ASSEMBLY — Apple Inc. (USA) — Various components of an electronic device housing and methods for their assembly are disclosed. The housing can be formed by assembling and connecting two or more different sections which may be extruded aluminum that are anodized. The sections of the housing may be coupled together using one or more coupling members. The coupling members may be formed using a two-shot molding process in which the first shot forms a structural portion of the coupling members, and the second shot forms cosmetic portions of the coupling members.

US10285294 — METHOD FOR PRODUCING A CHASSIS MEMBER USABLE IN A CHASSIS OF AN ELECTRONIC DEVICE — Lenovo (Singapore) PTE Ltd. (Singapore) — A chassis member for a chassis of an electronic device is disclosed. The chassis member includes an aluminum alloy layer and an anodized layer serving as an outermost layer of the chassis member and disposed on a surface of the aluminum alloy layer. A grain size of an aluminum alloy in the aluminum alloy layer is between 40 μm and 50 μm.

US10280521 — FLUORINATED ACID COMPOUNDS, COMPOSITIONS AND METHODS OF USE — Win Chemicals, Ltd. and Vitech International, Inc. (USA) — Novel acid-based chemistries that can be used in various cleaning, de-scaling, rust-removal, brightening, etching, and other similar applications, including, but not limited to, those based upon hexafluorozirconic acid and other additives, such as urea in some applications, which are effective for a wide range of applications, while avoiding the health, safety and environmental issues that are often associated with the use of hydrochloric acid and other toxic chemistries.

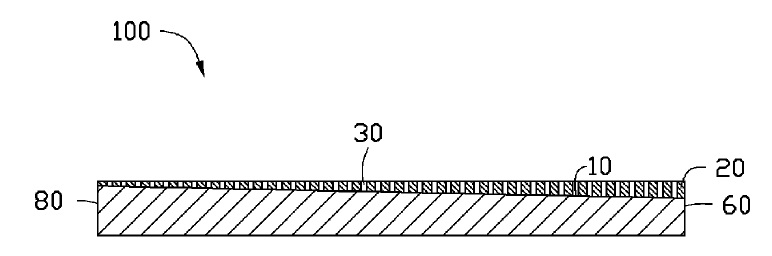

US10280516 — ENCAPSULATION OF A STIFFENER LAYER IN ALUMINUM — Apple Inc. (USA) — The described embodiments relate to methods and apparatus for increasing rigidity of a metal housing while maintaining or reducing a wall thickness of the metal housing. More particularly a method for embedding a stiffener layer within an anodized aluminum substrate is discussed. In one exemplary embodiment the stiffener layer can be a carbon fiber sheet applied to an inside surface of an unfinished housing and then subsequently covered by depositing a layer of aluminum over the carbon fiber in a solid-state deposition process. The deposited aluminum can adhere to the unfinished housing around or through the carbon fiber layer to bond with the unfinished housing. Deposition parameters can be controlled to prevent damage to the carbon fiber sheet.

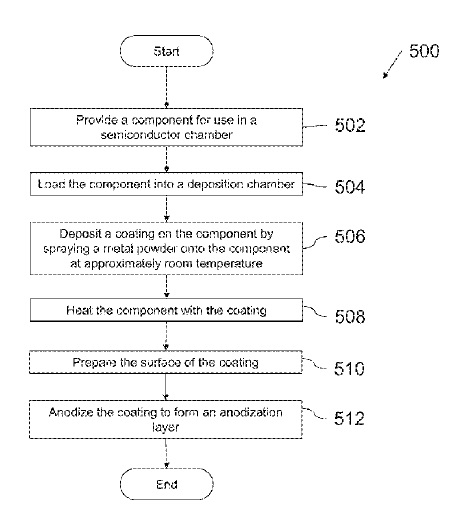

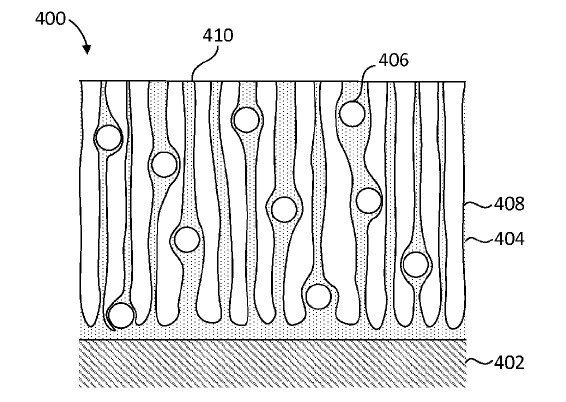

US10260160 — HIGH PURITY METALLIC TOP COAT FOR SEMICONDUCTOR MANUFACTURING COMPONENTS — Applied Materials, Inc. (USA) — A component, which may be aluminum or an aluminum alloy, for a manufacturing chamber comprises a coating and an anodization layer on the coating. The anodization layer has a thickness of about 2-10 mil. The anodization layer comprises a low porosity bottom layer portion having a porosity that is less than about 40-50% and a porous columnar top layer portion having a porosity of about 40-40% and comprising a plurality of columnar nanopores having a diameter of about 10-50 nm.

US10260153 — METHODS AND COMPOSITIONS FOR ACID TREATMENT OF A METAL SURFACE — Houghton Technical Corp. (USA) — The invention relates to compositions and methods that are useful in etching a metal surface. In particular, the invention relates to novel acid compositions and methods of using such compositions in etching a metal surface, preferably an aluminum surface prior to anodizing to dissolve impurities, imperfections, scale, and oxide. The compositions are effective in maintaining their etching capacity and in removing smut produced by the etching of a surface as well as in general cleaning.

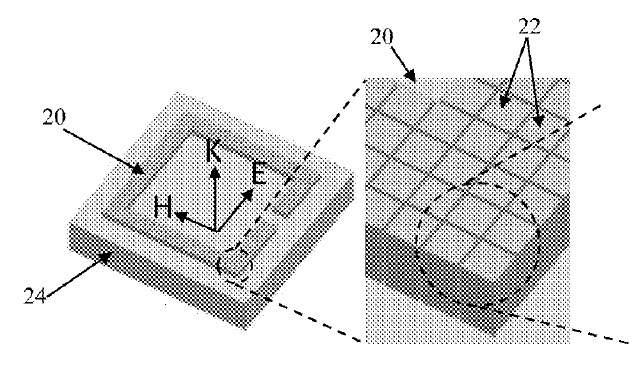

US10259704 — NANOPILLAR-BASED ARTICLES AND METHODS OF MANUFACTURE — Regents of the University of Minnesota (USA) — Nanopillar-based THz metamaterials, such as split ring resonator (SRR) MMs, utilizing displacement current in the dielectric medium between nanopillars that significantly increases energy storage in the MMs, leading to enhanced Q-factor. A metallic nanopillar array is designed in the form of a single gap (C-shape) SRR. Vacuum or dielectric materials of different permittivities are filled between the nanopillars to form nanoscale dielectric gaps. In other embodiments, formation of patterned nanowires using anodic aluminum oxide (AAO) templates with porous structures of different heights resulting from an initial step difference made by etching the aluminum (Al) thin film with a photoresist developer prior to the anodization process are disclosed.

US10236120 — MANUFACTURE OF COILS FOR ELECTROTECHNICAL COMPONENTS USING STRIPS OF UNSEALED ANODIZED ALUMINUM — Safran Electrical & Power (France) — A method for manufacturing a strip of impregnated anodized aluminum, for use in a coil of an electrotechnical component, said coil including an interstitial material providing dielectric cohesion and insulation functions, said interstitial material being suitable for cross-linking, in other words for forming, by chemical reactions between the components thereof when subjected to certain physical conditions, molecular structures being organized in a lattice, the method comprising: a step of applying the precursor mixture of said interstitial material to the anodized aluminum; at least one step of cross-linking the precursor mixture in order to form said interstitial material on the strip of aluminum; wherein the anodized aluminum has not been subjected to the sealing of the pores of the alumina formed by anodization prior to the application of the precursor mixture of said interstitial material.

US10231352 — ANODIZING RESISTANT COMPONENTS AND METHODS OF USE THEREOF — Apple Inc. (USA) — Methods and structures for forming anodization layers that protect and cosmetically enhance metal surfaces are described. In some embodiments, methods involve forming an anodization layer on an underlying metal that permits an underlying metal surface to be viewable. In some embodiments, methods involve forming a first anodization layer and an adjacent second anodization layer on an angled surface, the interface between the two anodization layers being regular and uniform. Described are photomasking techniques and tools for providing sharply defined corners on anodized and texturized patterns on metal surfaces. Also described are techniques and tools for providing anodizing resistant components in the manufacture of electronic devices.

US10214827 — MICROCRYSTALLINE ANODIC COATINGS AND RELATED METHODS THEREFOR — Sanford Process Corporation (USA) — Methods of preparing metal and metal alloys, particularly aluminum and aluminum alloys, with partially microcrystalline anodic coatings are disclosed. Associated articles therefrom are correspondingly disclosed. The partially microcrystalline anodic coatings exhibit fade and pattern removal resistance when subjected to sterilization processes. Partially microcrystalline anodic coating can be prepared by impregnation of micropores of a metal or metal substrate with metal precursor species, conversion of the metal precursor species into metal hydroxides, and one or more additional treatments to promote phase transformation of the metal hydroxide product into metal oxides solids and bonding with metastable metal oxide substance in the pore structure of the metal or metal alloy substrate.

US10208783 — WHEEL NUT AND METHOD OF MANUFACTURING WHEEL NUT — Hyundai Motor Company and Kia Motors Corporation (Korea) — Disclosed herein is a method of manufacturing a wheel nut. The method includes annealing an aluminum (Al) alloy material and preheating the annealed Al alloy material. The Al alloy material is also forged to form a wheel nut. Furthermore, the method includes performing an anodizing treatment to form a primary coating on the wheel nut and performing a vacuum deposition to form a secondary coating on the wheel nut. In addition, the method includes performing a surface treatment using powder paint to form a tertiary coating on the wheel nut.

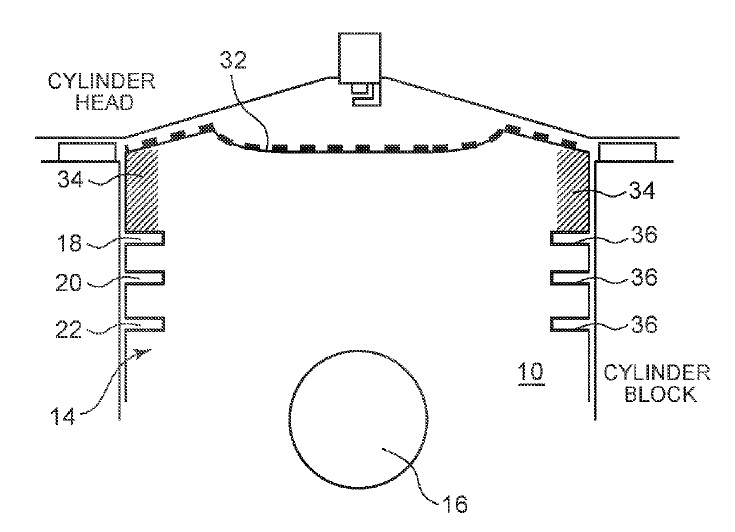

US10208703 — PISTON FOR INTERNAL COMBUSTION ENGINE, INTERNAL COMBUSTION ENGINE INCLUDING THIS PISTON, AND MANUFACTURING METHOD OF THIS PISTON — Toyota Jidosha Kabushiki Kaisha (Japan) — There is provided a piston for an internal combustion engine, the piston including: a heat-shielding (alumite/ceramic) film provided to an upper surface of a land part of the piston, the heat-shielding film having a lower thermal conductivity than a piston base material and having a lower heat capacity per unit volume than the piston base material; and a first heat-retaining film provided to a side surface of the land part, the first heat-retaining film having a lower thermal conductivity than the piston base material and having a higher heat capacity per unit volume than the heat-shielding film. The first heat-retaining film is a hard alumite having a lower porosity than the heat-shielding film resulting in the higher heat capacity per unit volume than the heat-shielding film.

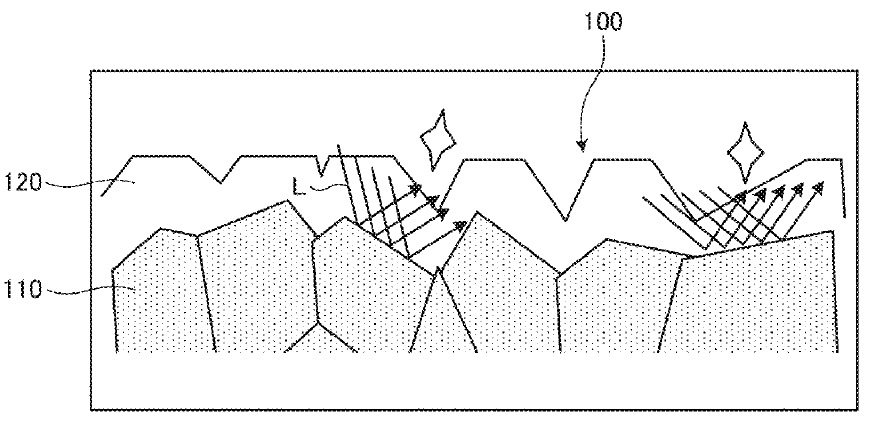

US10197750 — AAO-BASED LIGHT GUIDING STRUCTURE AND FABRICATION THEREOF — Sensor Electronic Technology, Inc. (USA) — A light guiding structure is provided. The structure includes an anodized aluminum oxide (AAO) layer and a fluoropolymer layer located immediately adjacent to a surface of the AAO layer. Light propagates through the AAO layer in a direction substantially parallel to the fluoropolymer layer. An optoelectronic device can be coupled to a surface of the AAO layer and emit/sense light propagating through the AAO layer. Solutions for fabricating the light guiding structure are also described.

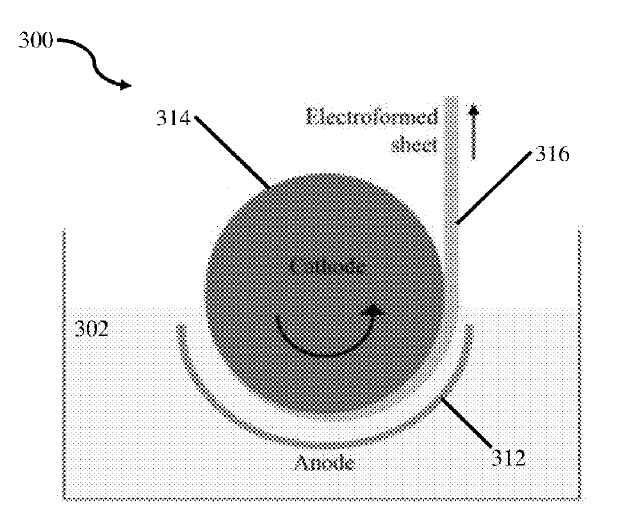

US10190227 — ARTICLES COMPRISING AN ELECTRODEPOSITED ALUMINUM ALLOYS — Xtalic Corporation (USA) — Electrodeposited stable nano structured aluminum manganese alloys exhibit an exceptional combination of high hardness and tensile ductility. In addition to the combination of high hardness and tensile ductility, the alloys are approximately the same density as other aluminum alloys. This combination of high strength, ductility, and light weight make it an ideal structural material for applications such as armor, aircraft, sporting equipment, and other applications where a light weight high strength ductile material would be of benefit. An article comprising an electrodeposited aluminum alloy is described herein. The electrodeposited aluminum alloy comprises an average grain size less than approximately 1 micrometer. The electrodeposited aluminum alloy thickness is greater than approximately 40 micrometers. A ductility of the electrodeposited aluminum alloy is greater than approximately 2%.

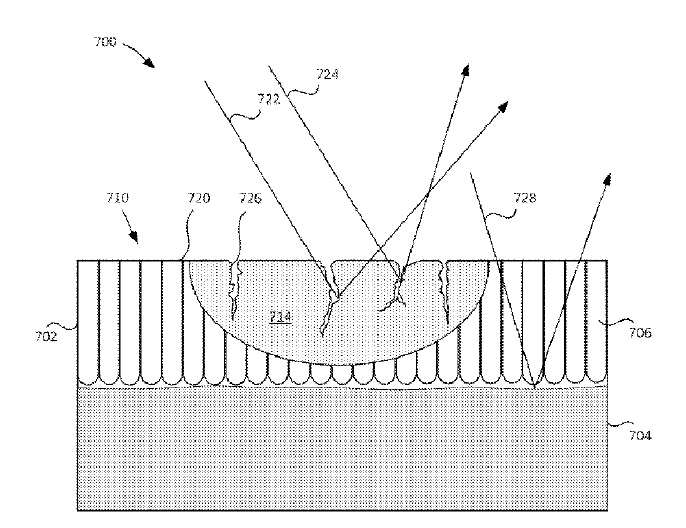

US10184190 — WHITE APPEARING ANODIZED FILMS — Apple Inc. (USA) — The embodiments described herein relate to forming anodized films that have a white appearance. In some embodiments, an anodized film having pores with light diffusing pore walls created by varying the current density during an anodizing process is described. In some embodiments, an anodized film having light diffusing micro-cracks created by a laser cracking procedure is described. In some embodiments, a sputtered layer of light diffusing aluminum is provided below an anodized film. In some embodiments, light diffusing particles are infused within openings of an anodized layer.

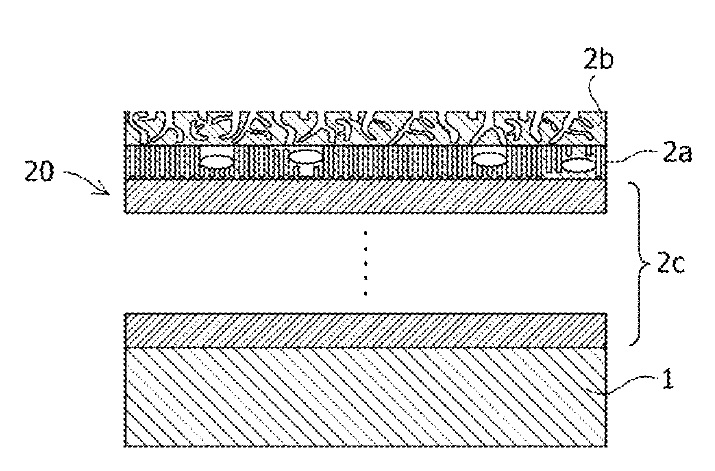

US10179956 — ANODIC OXIDE COATING, TREATMENT METHOD THEREFOR, AND PISTON FOR INTERNAL COMBUSTION ENGINE — Suzuki Motor Corporation (Japan) — Provided are an anodic oxide coating for an aluminum-based material, a treatment method therefor, and a piston for an internal combustion engine, the anodic oxide coating having both high heat insulation properties and high corrosion resistance, high durability and high impact resistance, and high water-repellent and oil-repellent functions. The treatment method includes the steps of: forming a second anodic oxide coating 2b by application of AC-DC superimposition electrolysis to an aluminum-based material 1; and, after the step, forming a first anodic oxide coating 2a by application of direct-current electrolysis to the aluminum-based material 1, wherein the second anodic oxide coating 2b is formed on the first anodic oxide coating 2a.

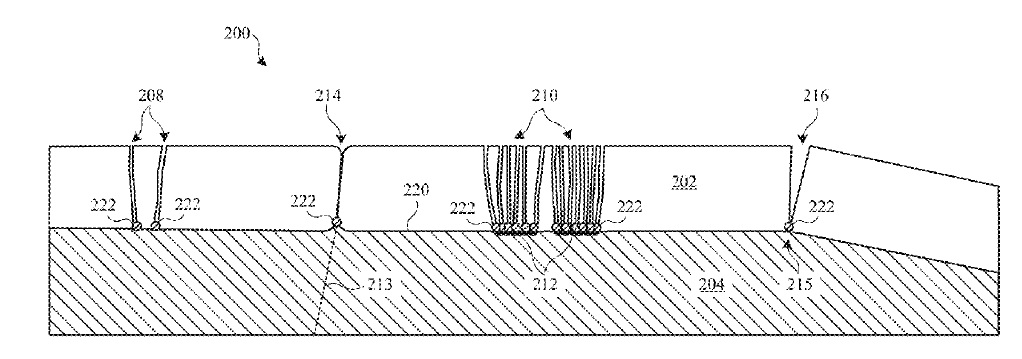

US10174436 — PROCESS FOR ENHANCED CORROSION PROTECTION OF ANODIZED ALUMINUM — Apple Inc. (USA) — Processes for enhancing the corrosion resistance of anodized substrates are disclosed. In some embodiments, the process involves a second anodizing operation that targets an area of the substrate that is left inadequately protected by a first anodizing operation, and also targets defects that may have been arisen from intermediate processing operations such as laser-marking operations. The second anodizing operation can be conducted in a non-pore-forming electrolyte and grows a thick protective barrier film over inadequately protected areas of the substrate, such as laser-marking treated areas.

US10165699 — OXIDIZED AND COATED ARTICLES AND METHODS OF MAKING SAME — Hewlett-Packard Development Company, L.P. (USA) — The housing of electronic devices, particularly those of portable electronic devices, is frequently subject to mechanical deformation due at least in part to its frequent contact with other objects (e.g., table, hand, ground, etc.). These devices, particularly the housing thereof, often need to have materials having high mechanical strength and high hardness, so as to withstand wear. At the same time, the housing structure often has certain cosmetic features that make the structure at least visually appealing to a consumer user. One example provides a method of manufacturing. The method comprises oxidizing, using plasma, a first surface of a substrate comprising a metal-material such as aluminum. The method further comprises cutting into the substrate through the oxidized first surface to expose a non-oxidized second surface of the substrate, the second surface not parallel to the first surface. The method further comprises disposing, using electrophoretic deposition, a coating layer over the exposed second surface to form an article having the oxidized first surface and the coated second surface.

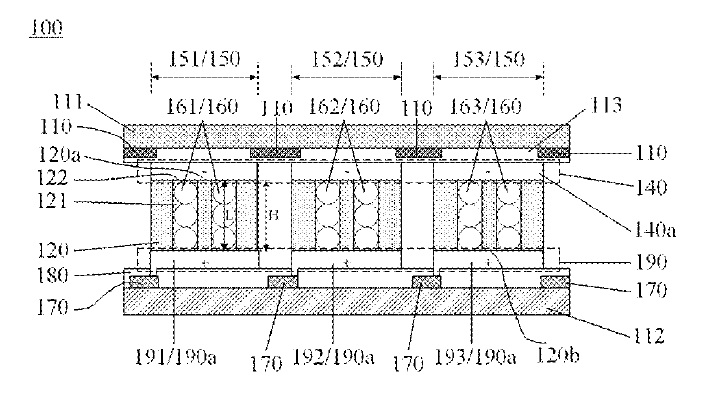

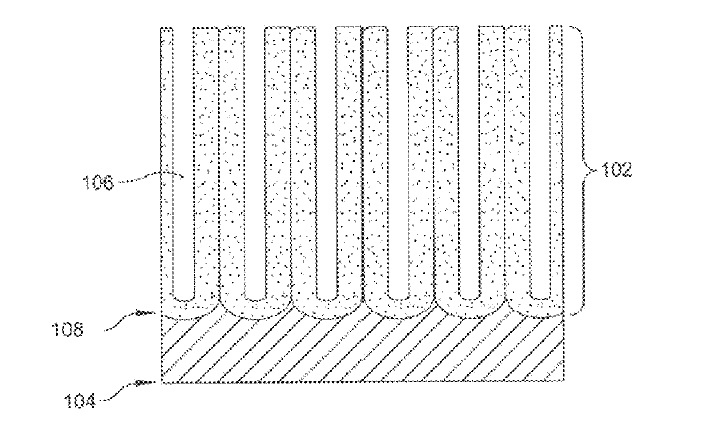

US10163567 — MULTI-LAYERED ALUMINUM OXIDE CAPACITOR — Point Engineering Co., Ltd. (Korea) — The present invention relates to a multi-layered aluminum oxide capacitor comprising an aluminum substrate; a plurality of aluminum oxide layer formed in at least a portion of on both sides or one side of the substrate with respect to the aluminum substrate; and a plurality of electrode layers formed on the aluminum oxide layers. According to the present invention, manufacturing process is more simplified since Al2O3 insulation layer is formed by anodizing the aluminum layer without forming an extra insulation layer after forming the aluminum layer, so that the manufacturing cost can be reduced, and also a multi-layered capacitor having a high capacitance and a high reliability can be provided by stacking capacitors comprising a plurality of aluminum oxide layers using a more simplified process according to the present invention.

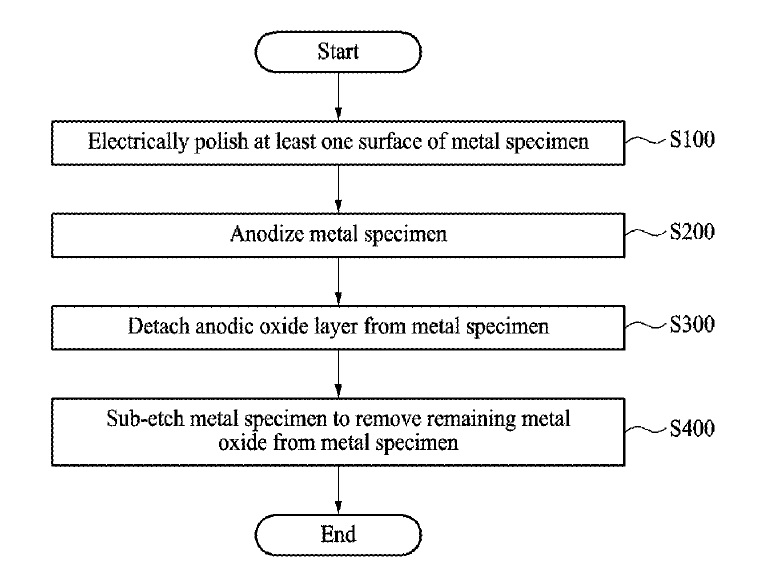

US10156018 — METHOD FOR MANUFACTURING ANODIC METAL OXIDE NANOPOROUS TEMPLATES — Korea University Research and Business Foundation (Korea) — Disclosed is a method for manufacturing anodic metal-oxide nanoporous templates with high-yield and in an environmentally-friendly manner. The method includes anodizing a metal specimen and detaching nanoporous anodic oxide layers, which are formed on more than one surface of the metal specimen due to the anodizing, from the metal specimen, wherein the detaching of the nanoporous anodic oxide layers from the metal specimen includes applying a reverse bias to the metal specimen in the same acidic electrolyte used for anodization. In an embodiment, a method for manufacturing anodic metal-oxide nanoporous templates may include (a) preparing an aluminum specimen, (b) electro-polishing the multi-surfaces of the aluminum specimen in a electrolyte based on perchloric acid and ethanol, (c) pre-anodizing the electro-polished aluminum specimen in a sulfuric acid electrolyte by applying a anodic (forward) bias for anodization to the electro-polished aluminum specimen, (d) main-etching pre-anodized aluminum oxide layers (pre-AAOs), which are generated by the pre-anodizing, through a chromic acid aqueous solution, (e) main-anodizing the aluminum specimen to form main-anodized aluminum oxides (main-AAOs) by dipping more than one surface of the aluminum specimen, which are textured through the pre-anodizing and etching, in a sulfuric acid solution and by reapplying a same anodic bias for anodization to the textured aluminum specimen, and (f) applying a reverse bias to the aluminum specimen to detach main-anodized aluminum oxide layers, which are generated by the main-anodizing, from the aluminum specimen.

US10155340 — MOLD, METHOD FOR PRODUCING MOLD, AND METHOD FOR PRODUCING NANOIMPRINT FILM — Sharp Kabushiki Kaisha (Japan) — In the field of technology for producing optical materials having such nanostructured bodies, a known method uses a mold that is an aluminum substrate with nanometer-sized holes formed on the surface by anodization. This method allows formation of nanostructured bodies that are distributed microscopically irregularly (at random) and are distributed macroscopically regularly. That is, employment of this method in production of an imprint roller allows formation of seamless nanostructured bodies, which is needed for continuous production, on the surface of a pillar- or cylinder-shaped mold roller. A mold is disclosed capable of producing a nanoimprint film without a problem of clogging of irregularities of the mold with a resin material. A method for producing the mold and a method for producing a nanoimprint film using the mold are further disclosed. In an embodiment, the mold includes: a first surface having a nanostructure including plural recesses spaced at an interval of less than 1 μm between bottom points of adjacent recesses; and at least two second surfaces substantially not having the nanostructure, wherein the first surface is coplanar with the at least two second surfaces and is positioned between two second surfaces.

US10138566 — A SEALING ANODIZED ALUMINUM USING A LOW-TEMPERATURE NICKEL-FREE PROCESS — MacDermid Acumen, Inc. (USA) — The inventive two-step process operates at low temperature, without any toxic heavy metals, to provide excellent sealing on anodized aluminum substrates, especially those aluminum substrates comprising silicon. The first step of the process seals the anodized surface and the second step passivates the anodized surface. The process allows for corrosion resistance in anodized aluminum and anodized aluminum alloys to be achieved that is comparable to traditional nickel based sealants, without the toxicity of nickel. The process additionally does not require any excessive temperatures, as required by hot water sealing processes. The composition used for the sealing step comprises soluble lithium ions, fluoride ions, and preferably, a complexing agent comprising phosphines, phosphonates and/or polymers of acrylic acid. The composition used for the passivation step comprises metal ions and preferably a complexing agent comprising phosphines, phosphonates and/or polymers of acrylic acid.

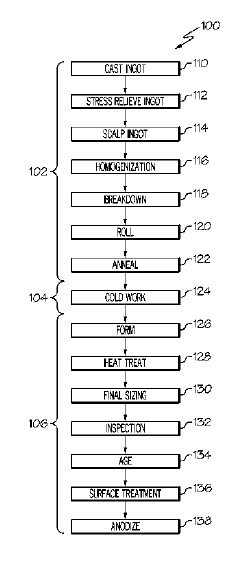

US10030294 — METHOD FOR MANUFACTURING ANODIZED ALUMINUM ALLOY PARTS WITHOUT SURFACE DISCOLORATION — The Boeing Company (USA) — When certain aluminum alloys, such as 2219 aluminum alloy, are used to form lipskins, discoloration is often visible in the final anodized part. For example, the discoloration can appear as visible lines of discoloration on the surface of the part. The discoloration typically presents itself after the forming (e.g., spin-forming) step, but becomes much more acute after anodizing. A method for manufacturing a part comprising: providing an aluminum starting material for a lipskin, wherein said aluminum starting material is an annealed and cold worked condition, said aluminum cold worked material having substantially uniform stresses therein; forming said part from said aluminum cold worked material having said substantially uniform stresses therein such that non-uniform stresses are introduced to the aluminum cold worked material, wherein said forming includes forming said part to have a non-planar configuration; solution heat treating said part having said substantially uniform stresses therein and having said non-uniform stresses therein, thereby yielding a solution heat treated part having a recrystallized grain structure; and anodizing said solution heat treated part.

US9879355 — METHOD FOR ANODIZING PARTS MADE OF AN ALUMINUM ALLOY — Mecaprotec Industries (France) — A method for anodizing a part made of aluminum or an aluminum alloy by immersing the part in an aqueous bath essentially comprising sulfuric acid at a concentration of 150 to 250 g/L and at a temperature of 5 to 25oC. A DC voltage according to a voltage profile comprising a voltage increased at a rate of 1 to 32 V/min is applied to the part. The voltage is maintained at a plateau voltage value of 12 to 20 V for a duration sufficient for obtaining, at the surface of the part, an anodized layer having a thickness of 3 to 7 μm and/or a layer weight of 20 to 150 mg/dm2.

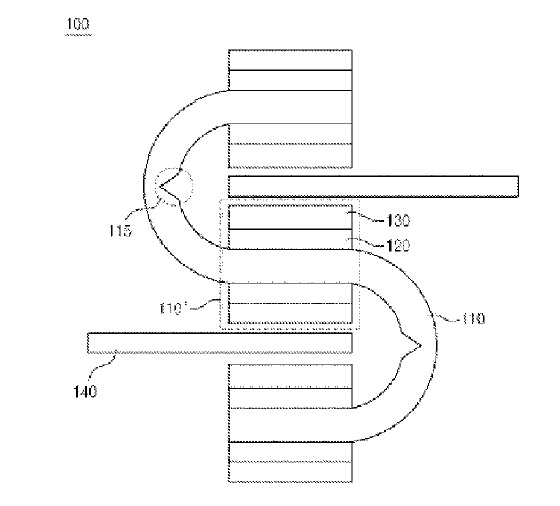

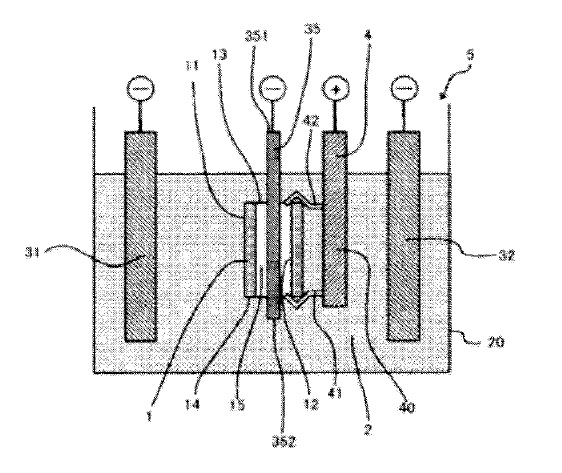

US9790612 — ANODIZING METHOD OF ALUMINUM — Denso Corporation (Japan) — In an anodizing method of aluminum, a tubular object made of aluminum or aluminum alloy is located between a pair of cathodes in an electrolysis solution, and a subsidiary cathode is inserted into the tubular object. The tubular object is anodized in the electrolysis solution to form an anodic oxide coating on an inner surface of the tubular object and on an outer surface of the tubular object. Accordingly, the anodic oxide coating can be formed easily not only on the outer surface of the tubular object but also on the inner surface of the tubular object. Therefore, a thickness difference of the anodic oxide coating between on the outer surface of the tubular object and on the inner surface of the tubular object can be reduced.

US9790611 — PARTIAL ANODIZING APPARATUS AND ANODIZING METHOD USING THE SAME — Aisin Keikinzoku Co., Ltd. (Japan) — An apparatus and a method are disclosed that form an anodic oxide coating on part of the outer surface of a profile having an irregular cross-sectional shape. A partial anodizing apparatus that is used to partially anodize a profile having an irregular cross-sectional shape includes an electrolytic bath that is divided into two or more partial baths. The profile is held using the two or more partial baths so that part of the profile is situated outside the electrolytic bath to form a sealed electrolysis chamber.

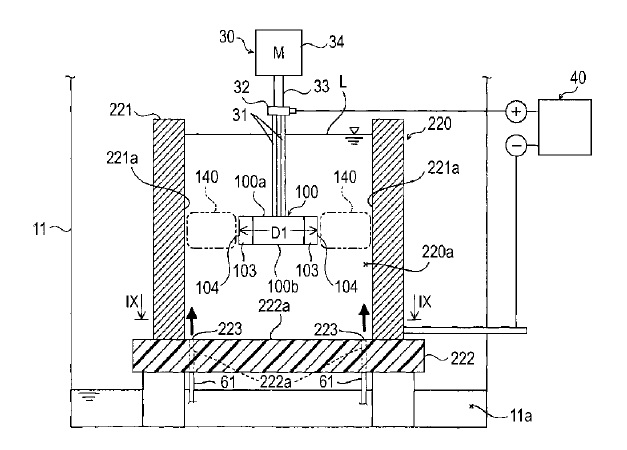

US9617651 — ANODIZING APPARATUS AND ANODIZING METHOD — Aisin Seiki Kabushiki Kaisha (Japan) — An anodizing apparatus configured to perform an anodization on a metallic material to be processed provided with a projecting portion on a surface thereof, includes: an electrolysis tank configured to store electrolytic solution for anodization; a first electrode portion formed of a metal and electrically connected to the material in an immersed state immersed in the electrolytic solution in the electrolysis tank; a second electrode portion formed of a metal and opposing the material in the immersed state; an electrode apparatus configured to apply a predetermined voltage between the first and second electrode portions; a retaining device configured to retain and rotate the material in the immersed state; and a first injection device configured to inject the electrolytic solution toward a predetermined area deviated from the material in a storage space in the electrolysis tank so that the material is deviated from a line in the direction of injection.

US9458547 — METHOD FOR ANODIZING AND DYEING METALLIC ARTICLE — Fu Tai Hua Industry (Shenzhen) Co., Ltd. (China) and Hon Hai Precision Industry Co., Ltd. (Taiwan) — A method for anodizing and dyeing a metallic article including a first dipped end, a second dipped end opposite to the first dipped end, and a decorated surface located between the first dipped end and the second dipped end, includes steps as follows: anodizing the metallic article to form an anodization layer on the decorated surface by an anodizing treatment, in which the anodization layer is porous with a number of holes, an immersion time of the decorated surface immersed in the electrolyte solution changes gradually from the first dipped end toward the second dipped end, and a depth of the plurality of holes of the anodization layer after the anodizing step thereby changes gradually from the first dipped end toward the second dipped end; and coloring the metallic article sealed in a dyeing treatment.

US9420713 — DOUBLE ANODIZING PROCESSES — Apple Inc. (USA) — Methods and structures for forming anodization layers that protect and cosmetically enhance metal surfaces are described. In some embodiments, methods involve forming an anodization layer on an underlying metal that permits an underlying metal surface to be viewable. In some embodiments, methods involve forming a first anodization layer and an adjacent second anodization layer on an angled surface, the interface between the two anodization layers being regular and uniform. Described are photomasking techniques and tools for providing sharply defined corners on anodized and texturized patterns on metal surfaces. Also described are techniques and tools for providing anodizing resistant components in the manufacture of electronic devices.

US9382637 — METHOD OF ANODIZING HOLLOW METALLIC BODIES — Thomas GmbH (Germany) — A plurality of cup-shaped workpieces are anodized by first securing each of them in a downwardly open position on an electrically conductive and flat workpiece frame that is then inverted such that the workpieces are open upward and lowered into a body of anodizing liquid in a treatment bath until the workpieces are wholly immersed and the frame is in contact with a horizontal rail. Thereafter the frame is moved horizontally while wholly immersed in the anodizing liquid while electricity flows between the rail and a cathode immersed in the bath below the workpieces such the liquid anodizes surfaces of the workpieces. The frame is raised out of the body of liquid with the workpieces open upward, and, while the workpieces are still above the body of liquid, inverting the frame and the workpieces so that the workpieces are open downward and any treatment liquid drains downward into the bath.

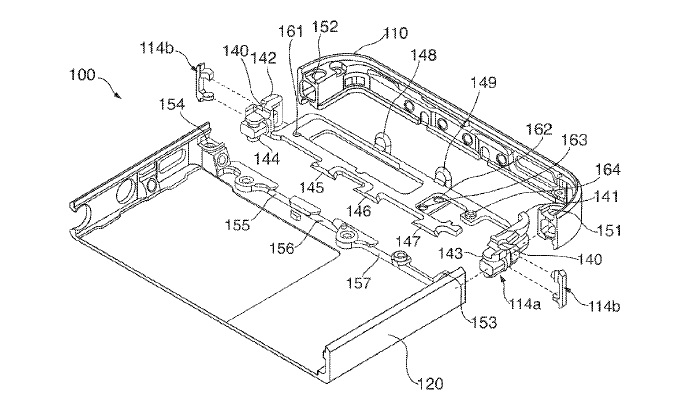

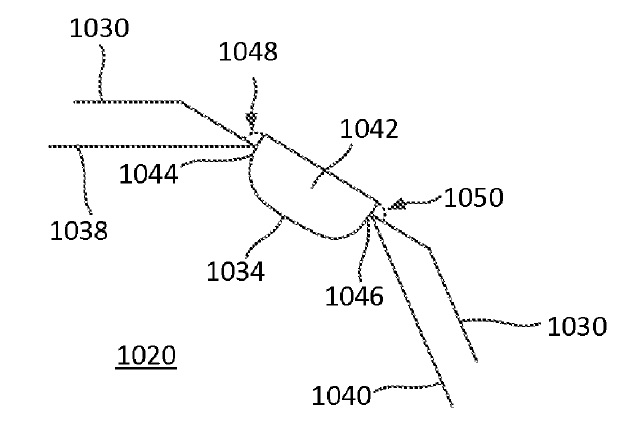

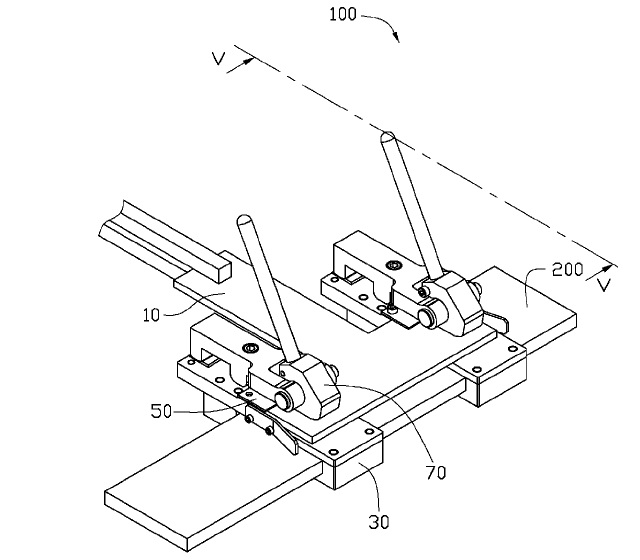

US9228271 — HANGING DEVICE FOR ANODIZING — Hon Hai Precision Industry Co., Ltd. (Taiwan) — A device for hanging a workpiece for anodizing includes a hanging member for fixing the workpiece, a positioning assembly, a latching assembly mounted on the positioning assembly, and a connecting rod assembly. The hanging member includes a latching end. The positioning assembly and the latching assembly cooperatively defines a latching space for positioning the hanging member. The connecting rod assembly includes a cam pivoted with the latching assembly, and a rod fixed with the cam. The cam includes a resisting end. The latching end of the hanging member is latched in the latching space. The cam is rotatable by means of the rod, such that the rod is capable of driving the resisting end of the cam to resist on the latching end to fix the hanging member, or to move away from the latching end to release the hanging member.

US9181629 — METHODS FOR PRODUCING WHITE APPEARING METAL OXIDE FILMS BY POSITIONING REFLECTIVE PARTICLES PRIOR TO OR DURING ANODIZING PROCESSES — Apple Inc. (USA) — The embodiments described herein relate to anodic films and methods for forming anodic films. The methods described can be used to form anodic films that have a white appearance. Methods involve positioning reflective particles on or within a substrate prior to or during an anodizing process. The reflective particles are positioned within the metal oxide of the resultant anodic film but substantially outside the pores of the anodic film. The reflective particles scatter incident light giving the resultant anodic film a white appearance.

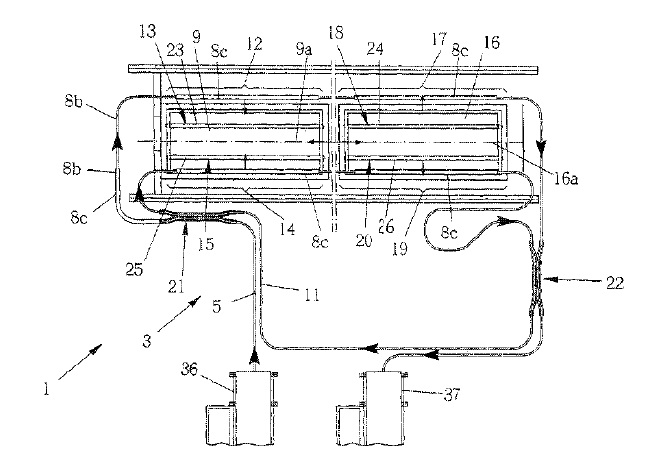

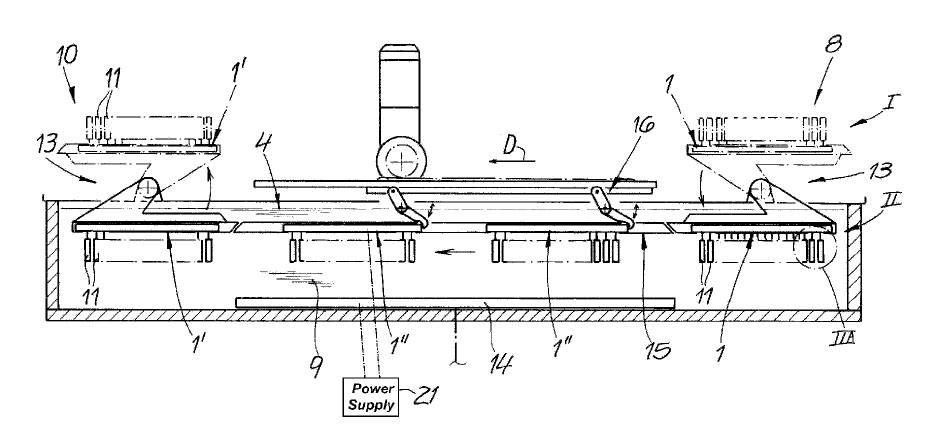

US9080249 — ANODIZING TREATMENT STATION IN A VERTICAL PAINT PLANT OF ALUMINUM PROFILES AND PAINT PLANT INTEGRATING SUCH ANODIZING TREATMENT STATION — SAT (Surface Aluminum Technologies) S.p.A. (Italy) — The anodizing treatment station (3) in a vertical paint plant (2) of aluminum profiles hanging in succession by means of hooks (8) on a main overhead conveyor (4) moving along a main conveyor line (5) which passes through at least one pre-treatment station and at least one powder or liquid paint station, comprises at least one oxidation bath (9) and a secondary overhead conveyor (10) moving along secondary conveyor line (11) in synchronism with said main conveyor (4), the main conveyor line (5) having a first main loading and/or unloading segment (12), facing said oxidation bath (9), wherein specific first main loading and/or unloading means (13) are adapted to transfer groups (8c) of hooks (8) from said main conveyor (4) to said oxidation bath (9) and/or vice versa, in that the secondary conveyor line (11) has a first secondary loading and/or unloading segment (14), facing said oxidation bath (9), wherein specific first secondary loading and/or unloading means (15) are adapted to transfer groups (8c) of hooks (8) from said secondary conveyor (10) to the oxidation bath (9) and/or vice versa, a first diverter (21) being provided which upstream of the oxidation bath (9) alternately transfers to the secondary conveyor (10) groups (8c) of hooks (8) conveyed by the main conveyor, and a second diverter (22) which to recompose the continuous succession of hooks (8) downstream of the oxidation bath (9) transfers the groups (8c) conveyed by the secondary conveyor (10) to the segments (8b) without hooks (8).