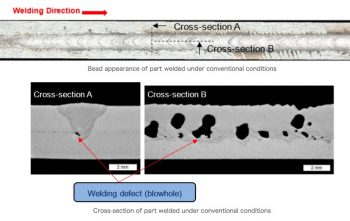

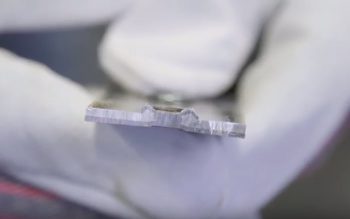

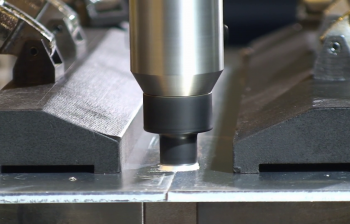

The Materials Testing Institute at the University of Stuttgart has developed a process, based on friction stir welding (FSW), for the high-strength welding of aluminum and steel plates. The plates can have different thicknesses and the seam is so stable that the hybrid plates can even be deep drawn. This enables lightweight yet sturdy hybrid […]