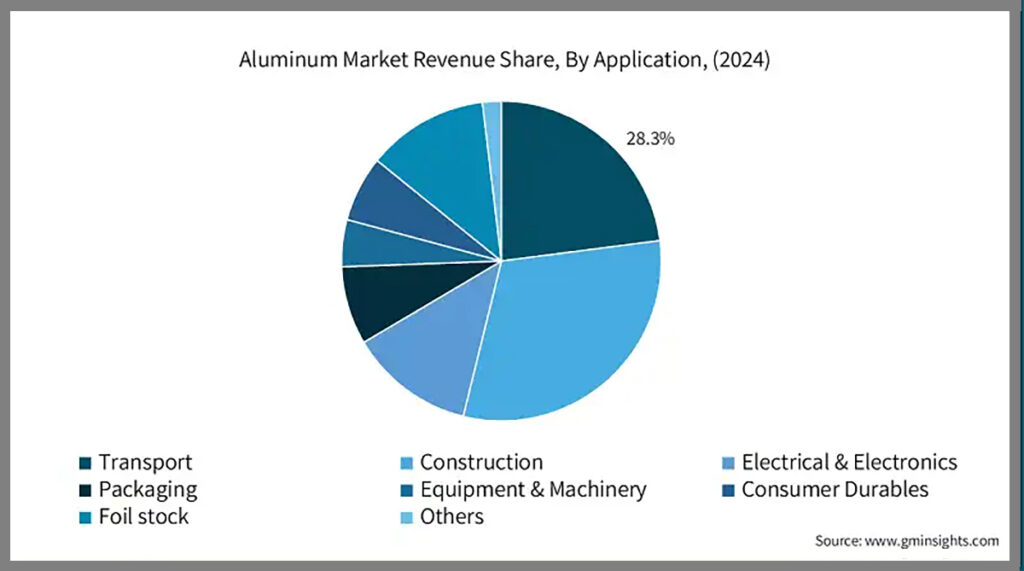

Editor’s Note: Driven by the demand for lightweight materials in the automotive industry, the transport segment remains the largest market segment in the global aluminum market. In 2024, this segment accounted for a market share of some 28% (Figure 1)—a figure that is expected to increase annually over the next decade.1

Not surprisingly, China’s transportation sector accounts for the largest share, followed by Europe and then North America. In the U.S., transportation accounted for 35% of the aluminum and aluminum products market in 2024.2

The largest sub-segment in the transportation sector remains automotive. Lots of aluminum is being used in passenger vehicles in structural components, powertrains, and other applications, in the form of castings, extrusion, and sheet. The reason for this is clear: Lightweighting improves fuel efficiency and lessens greenhouse gas emissions, which are still among the drivers for internal combustion engine vehicles.

Around 20% of greenhouse gas emissions are generated by the transportation sector, according to research from the International Energy Agency.3 Therefore, putting transportation vehicles on a diet is necessary toward cutting greenhouse gas emissions.

Of course, transportation as the aluminum industry’s largest market segment includes more than automotive. Aluminum is a popular choice for car bodies in high-speed trains, as well as in the bodies and other structural applications used for street and transit buses. In addition, shipbuilders build massive vessels with their hulls, cabins, and structural parts in aluminum, and fishing boats and pleasure crafts also use a lot of aluminum.

The inherent properties of this metal are just so incredibly useful across the transportation sector. Add to that the growing appetite for secondary metal and an improving reputation as a sustainable material, and it is easy to see how aluminum will remain a hot item in the transportation segment.

The patents presented below each have a link to the transport segment, and each was granted during the course of the past year. They are also available online at: https://patents.google.com, www.uspto.gov/patents/search, and https://patents.justia.com/patents-by-us-classification.

References

1. “Aluminum Market – By Product, By Processing Method, By Application – Global Forecast, 2025 – 2034,” Global Market Insights, February 2025.

2. “The U.S. Aluminum and Aluminum Products Market to reach $22 Billion by 2031,” IndustryARC.

3. “Light-Weighting Studies,” International Aluminium Institute.

— Kevin Widlic, Editor

U.S. Patents

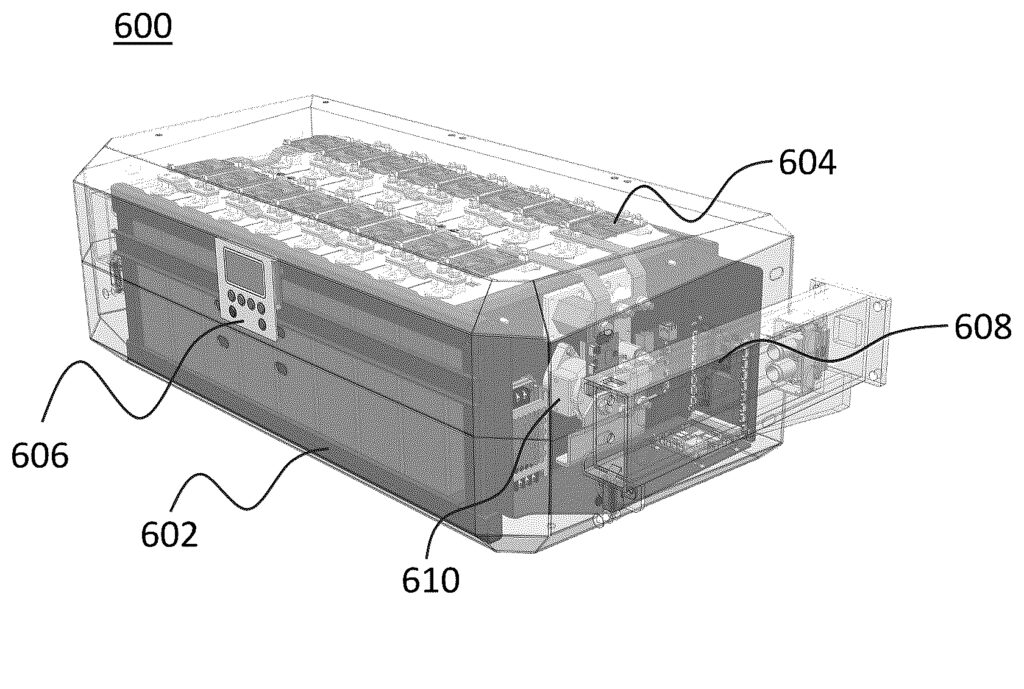

US12347834B1 — MODULAR HIGH-CURRENT BATTERY MANAGEMENT SYSTEM — Towflexx Miltech Inc. (USA) — An aircraft tow vehicle comprises a vehicle body, a turntable lifting unit coupled to the vehicle body configured to engage with an aircraft nose landing gear, and a modular high-current battery management system. The system includes at least one removable battery pack module housed within the vehicle body, comprising a battery frame housing a plurality of lithium iron phosphate (LiFePO4) batteries, a controller to monitor and control the batteries, a high-current DC power relay for managing current flow, at least one supercapacitor to manage changes in current flow, and at least one semiconductor device to regulate voltage and current levels. This enables the tow vehicle to perform efficient aircraft towing operations. The battery frame (602) may be constructed from lightweight aluminum alloys to minimize overall weight while providing robust structural support. In addition, the frame may include integrated cooling channels or heat sinks to facilitate thermal management of the battery cells, potentially improving performance and longevity.

US12391187B1 — CONVERTIBLE CARRIER RACK AND PLATFORM — Crooked Cedar Designs LLC (USA) — Vehicles for transportation have inherently limited cargo-carrying capacity based on vehicle size and external carrying ability, with external cargo transport typically involving roof-mounted or trailer-mounted devices. This device provides supplemental cargo carrying ability together with a flat, stable workspace, thereby negating the need to carry multiple devices to achieve the different goals. The device can be used in many applications, with a particular application as an automotive attachment to replace a roof or trailer cargo rack, where the cargo rack can be manipulated to function as a type of table. Embodiments of this disclosure include a flat surface with rails for the purpose of carrying cargo while attached to a vehicle, carried, or somehow otherwise transported. In various embodiments, one or more rails can pivot, rotate or detach and re-attach so as to convert to legs to form a table by use of the same flat surface. Components of the device can be fabricated from various types of materials, including aluminum.

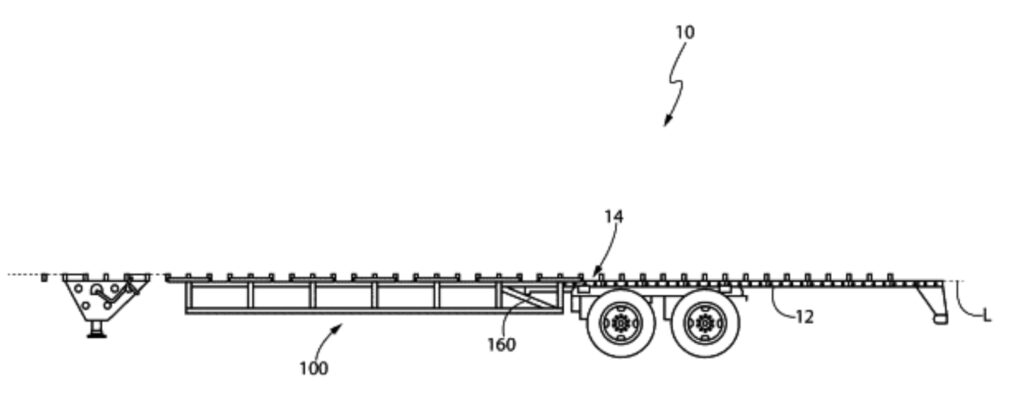

US12397729B1 — SIDE UNDERRIDE GUARD — Hcew Ip Leasing LLC (USA) — The invention is directed to side impact guard systems, such as a side underride guard for vehicles, including trailers for tractor-trailer rigs. In a first aspect of the invention, the side underride guard has an effective ground clearance on flat ground that is above bumpers and tires of the standard automobile as defined by the NHTSA but within the tire lift zone of wheel wells and below the top of structural elements at the back of the engine compartment. As a result, the body of the automobile and its frame below the windshield will reduce the likelihood of intrusion of the vehicle frame into the automobile passenger compartment. The side underride guard includes vertical sections extending downwardly from the structural siderail of the trailer. A horizontal beam extending longitudinally of the vehicle is fixed below the vehicle structural siderail to the lower ends of the vertical sections. The vertical section (110), horizontal section (112), and diagonal sections (114) can be formed from metal plates, tubes, formed angles, channels, and the like. If aluminum is used, then these sections can be made of tubes.

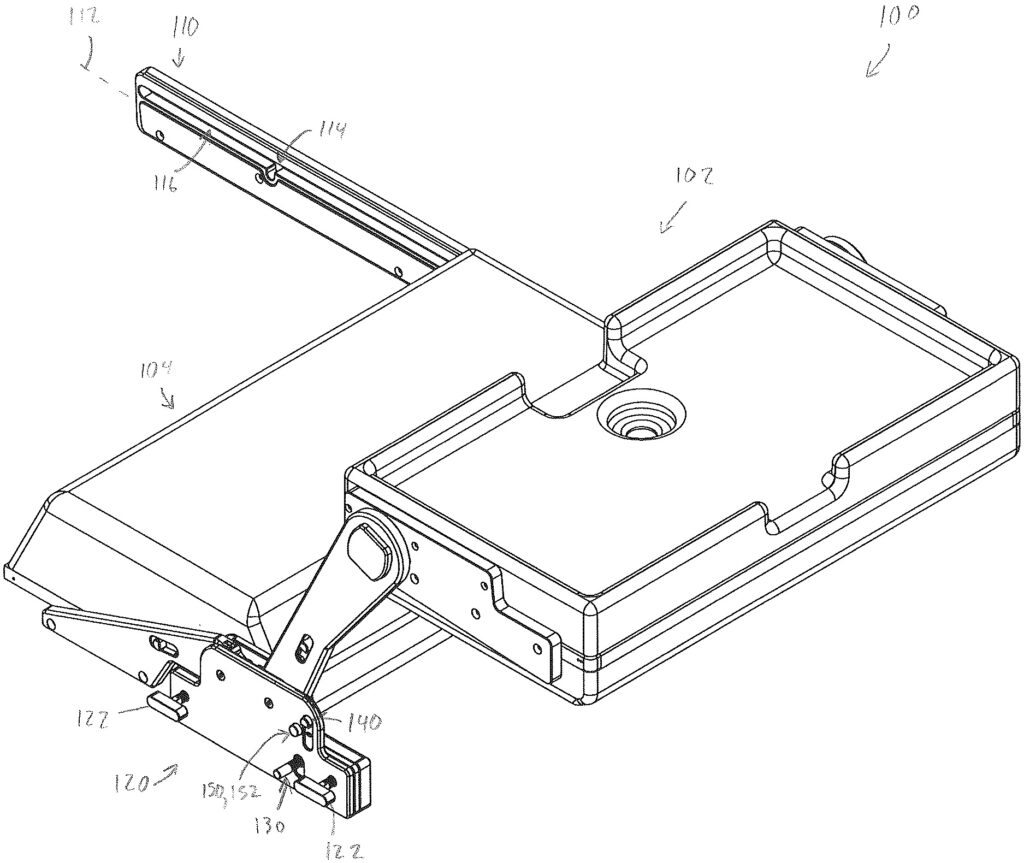

US12280857B1 — SEAT SLIDE-LOCK SYSTEM — Protomet Corp (USA) — Watercraft seating plays a crucial role in ensuring passenger comfort, safety, and enjoyment during marine activities. Traditionally, boat seats have been fixed in place or offered limited adjustment capabilities. However, modern watercraft designs often incorporate sliding seat systems that allow for greater flexibility in positioning and space utilization. The present disclosure provides a seat slide-lock system including a seat slide rail having a longitudinal axis and defining at least one detent, and a seat movable along the longitudinal axis of the seat slide rail. In some implementations, the seat slide rail (110) may be constructed from corrosion-resistant materials such as marine-grade aluminum, which may help prevent degradation when exposed to moisture or saltwater environments and enhance the system’s durability and longevity.

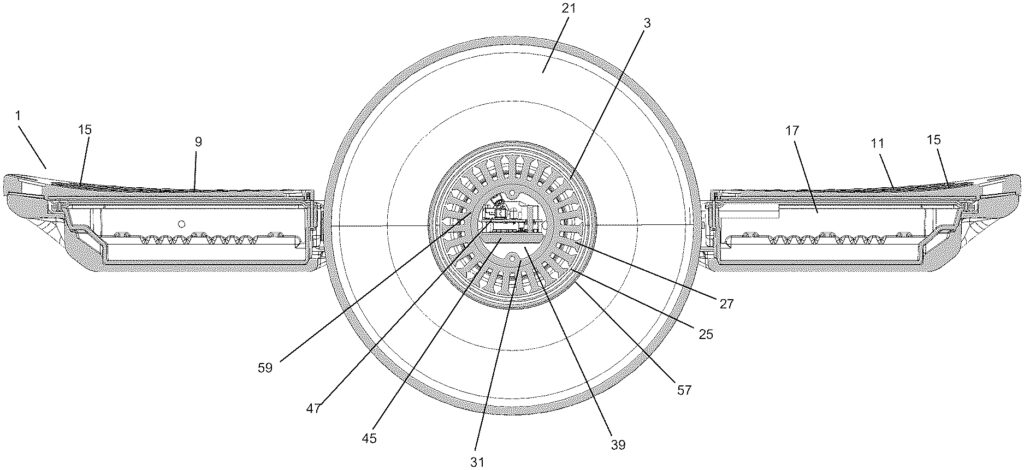

US12330736B1 — SINGLE-WHEELED VEHICLE WITH INCREASED TRAVEL RANGE — Float Supply LLC (USA) — Single-wheel electric vehicles are often used for personal transportation because they are portable and easy to operate. They often take the form of a board that surrounds the vehicle’s single wheel. The wheel contains a hub motor that in turn surrounds an axle that connects the single wheel to the board. A significant limitation of prior art vehicles, however, is that the vehicle’s travel range is limited by the vehicle’s battery capacity. In this disclosure, the hub motor includes an outer rotor which encloses a stator that in turn encloses an interior chamber within the motor that may be used to hold an electronic controller. The rotor (25) is preferentially formed from a metal material with high heat conductivity, such as aluminum. The additional capacity provided by the interior chamber allows the electric vehicle to hold more battery capacity, thereby extending the range of the electric vehicle between recharges.

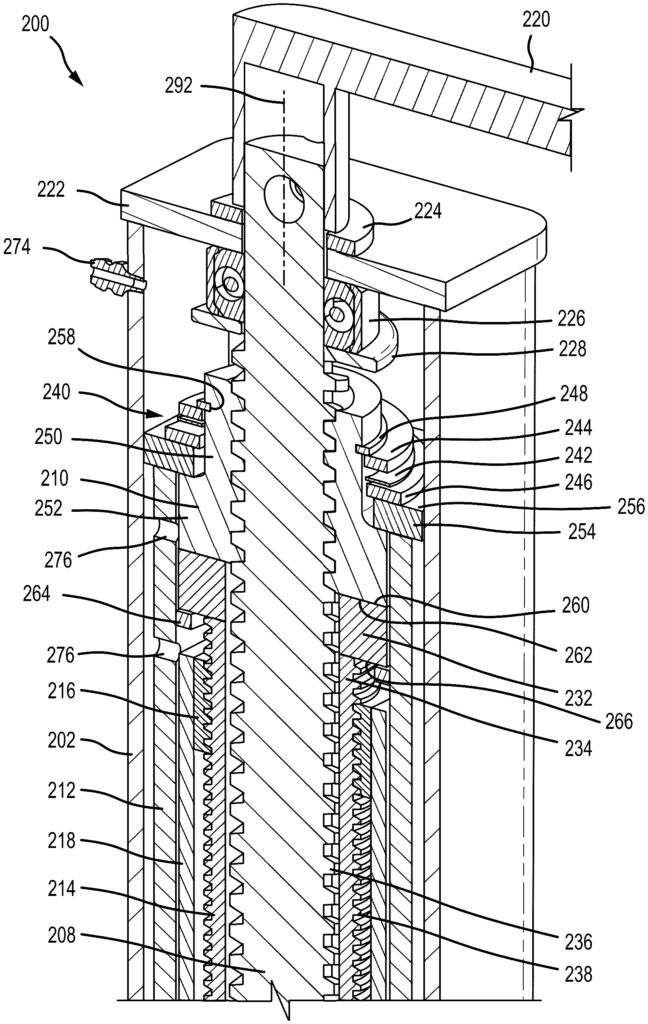

US12240421B1 — TWO-SPEED TRAILER JACK WITH FRICTION CLUTCH — SOS Solutions, Inc. (USA) — Many types of trailers that are towed by trucks are connected to the trucks by a releasable coupling such as a gooseneck coupling, a fifth-wheel coupling or a bumper pull coupling. After the trailer is released from the truck and is no longer supported by the truck at the forward end of the trailer, a lifting device, such as a jack, is often used to support the trailer floor or bed, typically in a position horizontal to the ground. The lifting device includes one or more vertically oriented columns, and a vertical leg is mounted on the column. One aspect of the subject matter described in this specification is embodied in a linear jack. The linear jack can include an outer tube, a first rotating screw, a coarse nut, a first sleeve, a second rotating screw, and a second sleeve. Various components of the lifting device (200) may be made from a metal, such as aluminum.

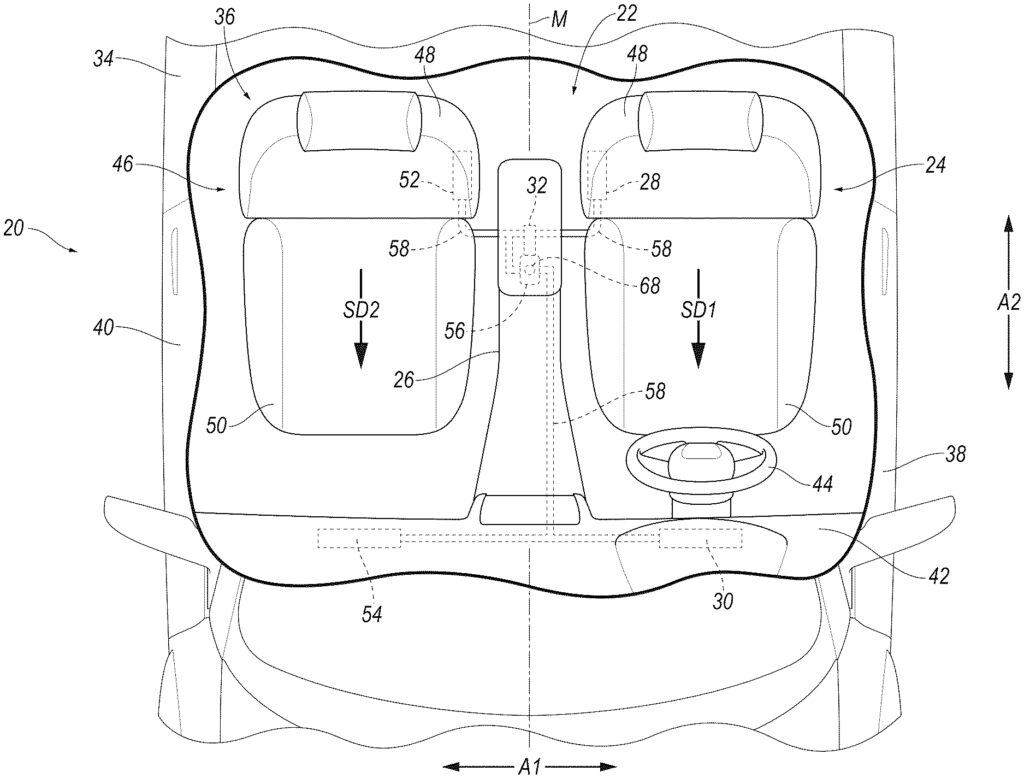

US12233807B1 — VEHICLE AIRBAG ASSEMBLY — Ford Global Technologies LLC (USA) — An assembly includes a seat assembly defining a seat-forward direction. This assembly includes a middle console adjacent to the seat assembly, and a first airbag inflatable from an uninflated position to an inflated position. The first airbag is supported by the seat assembly in the uninflated position and the inflated position. The assembly includes a second airbag inflatable from an uninflated position to an inflated position. The second airbag in the uninflated position and the inflated position is forward of the seat assembly in the seat-forward direction. The assembly includes an inflator supported by the middle console, the inflator operatively connected to the first airbag and the second airbag to provide inflation medium. The vehicle frame and the vehicle body (34) may be of any suitable material, such as aluminum.

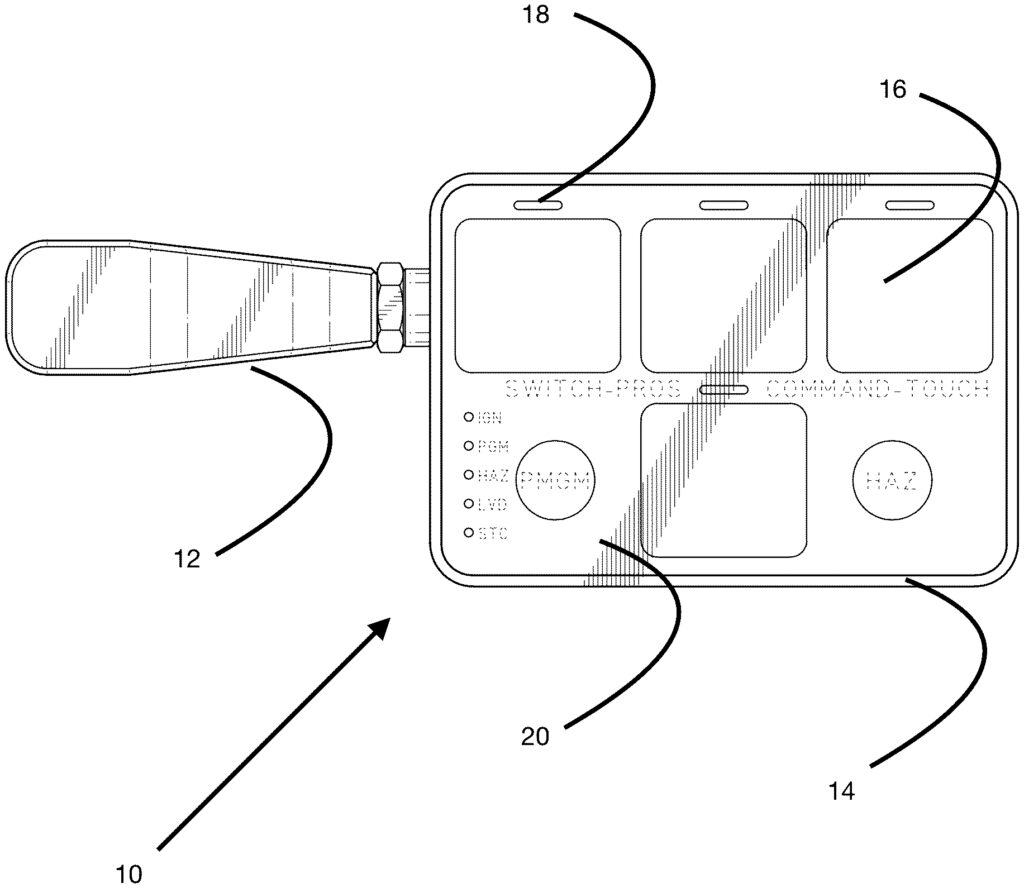

US12252070B1 — BLINKER MODULE — Off Road Engineering LLC (USA) — In general, offroad enthusiasts, in particular utility task vehicle (UTV) or side-by-side drivers, are often riding solo in their vehicles and want to control their aftermarket accessories without removing their hands from the steering wheel. Today, these vehicles do not tend to have any such mechanism by which to control their accessories. In this disclosure, there is contemplated a blinker module for controlling external turn signals. The blinker module includes a housing, a movable lever extending outward from one side of the housing, electronic components disposed within the housing to convey a position from the movable lever to the external signals, and a wire opening disposed on the rear of the housing. The housing of the blinker module as well as the lever may be made from a lightweight, yet strong metal, such as aluminum.

US12253238B1 — VEHICLE LIGHTING DEVICE — Hyundai Mobis Co., Ltd. (South Korea) — One aspect of the invention provides a vehicle lighting device including a housing mounted inside a vehicle, a light source part, and an aluminum film part of which a shape changes according to an operation of the light source part. The vehicle lighting device may further include a motor part that applies a load to the aluminum film part, wherein a shape of the aluminum film part may be deformed or restored according to the load applied by the motor part. When the load is applied by the motor part, at least a portion of the aluminum film unit may form a repeated pattern. When the load is not applied by the motor part, the formed pattern may be removed, and the aluminum film part may be restored to an original shape before formation of the pattern. The vehicle lighting device may further include a pattern plate through which a light emitted from the light source part, or a light reflected by the aluminum film part passes.

China Patents

CN118792551B — A HIGH-TEMPERATURE RESISTANT BRAZABLE DIE-CASTING ALUMINUM ALLOY — Suzhou Huijin New Material Technology Co., Ltd. (China) — In the modern automotive industry, heat exchanger systems are important components to ensure proper operation and high efficiency of vehicles. The systems realize key functions of engine cooling, air conditioning refrigeration and the like through heat transfer. As a core material of the heat exchanger, aluminum is widely used in the manufacture of the heat exchangers due to its excellent heat conductive property, light weight and corrosion resistance. Aluminum alloy plates and profiles are manufactured through extrusion, rolling and other processes, and have good mechanical properties and heat conductivity. In automotive heat exchangers, these materials are commonly used as components for fins, flow channels, and housings. This invention relates to the technical field of die-casting aluminum alloys, in particular to a high-temperature-resistant brazing die-casting aluminum alloy, and a preparation method and application thereof.

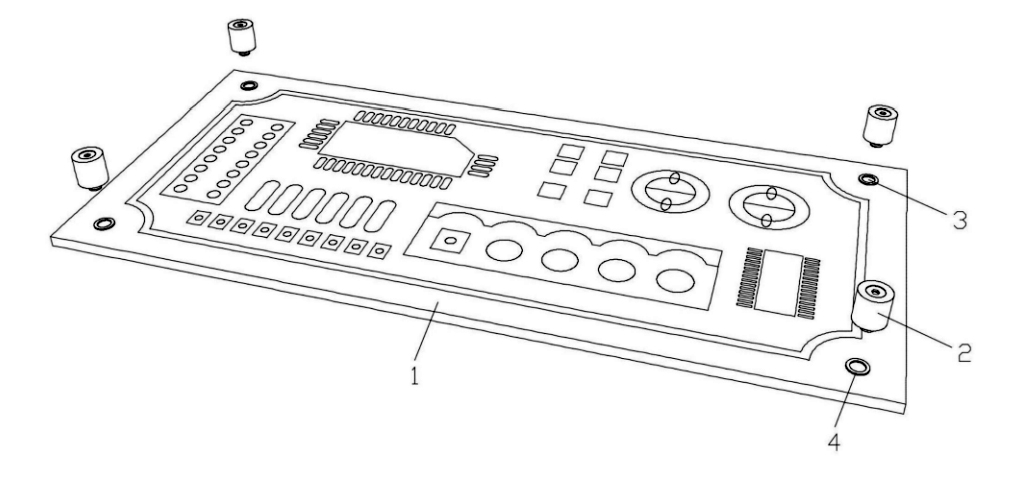

CN119172921B — AUTOMOBILE HEADLIGHT THERMOELECTRIC SEPARATION ALUMINUM-BASED CIRCUIT BOARD — Jiangxi Chengzhiyi Technology Co., Ltd. (China) — This invention discloses an aluminum-based circuit board for the thermoelectric separation of automobile headlights, which belongs to the technical field of aluminum-based circuit boards. This includes a circuit board body, wherein mounting holes are provided at the four corners of the circuit board body, a connecting cylinder is rotatably provided at the upper end of the connecting seat, a hexagonal bolt for fixing the circuit board body is slidably provided inside the connecting cylinder, and an auxiliary component for preventing the hexagonal bolt from being over-tightened and causing thread slipping is provided inside the connecting cylinder. This design helps dissipate heat more effectively, which is important for the performance and longevity of high-power LED car headlights.

CN119368664B — ASSEMBLY JIG AND CONTROL METHOD — Borg Jiangsu Metal Technology Co., Ltd. (China) — With the trend of automobile weight reduction, many traditional metal materials are being replaced, and aluminum is becoming the first choice of novel automobile structural materials due to lower density and good corrosion resistance. Particularly in the design of key parts such as threshold beams, the aluminum material can lighten the whole weight of the car body and improve the cruising performance of the car. However, aluminum faces more complicated processing requirements in the manufacturing process, especially in the production process of aluminum profiles of threshold beams, due to the complicated cross section and the large shape and structure changes at different positions. This invention aims to provide the assembly jig which can accurately fix the mounting point at the riveting hole on the threshold beam through optimizing the design of the positioning mechanism and the travel mechanism, effectively adapt to the complex section and shape change of the aluminum profile and reduce the debugging and operation time in the assembly process, thereby improving the production efficiency.

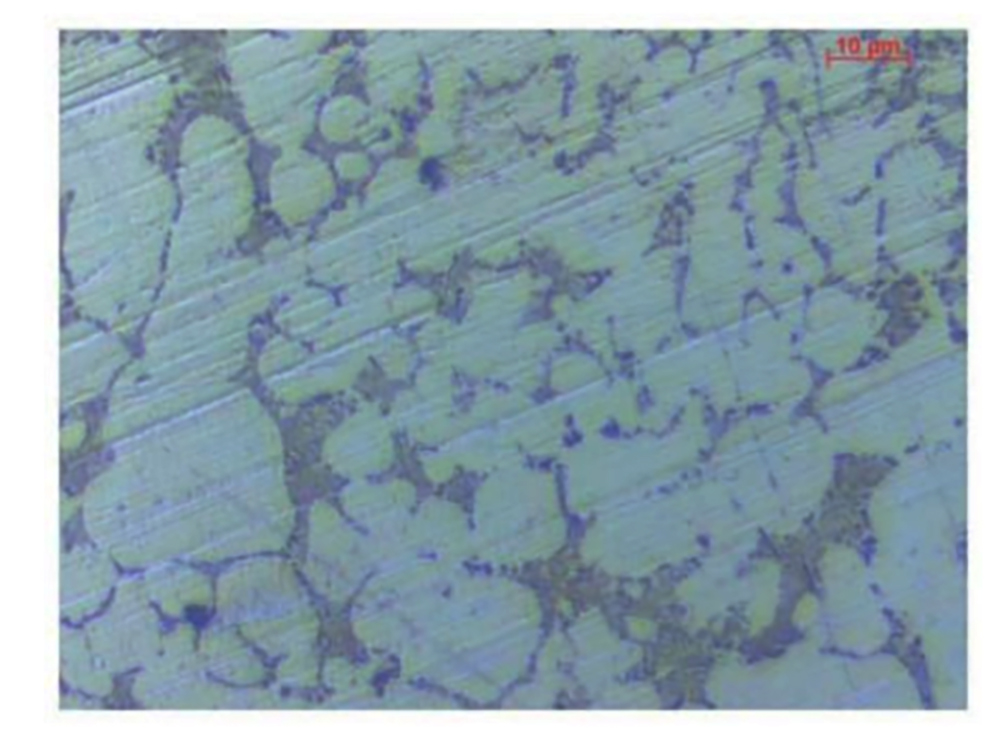

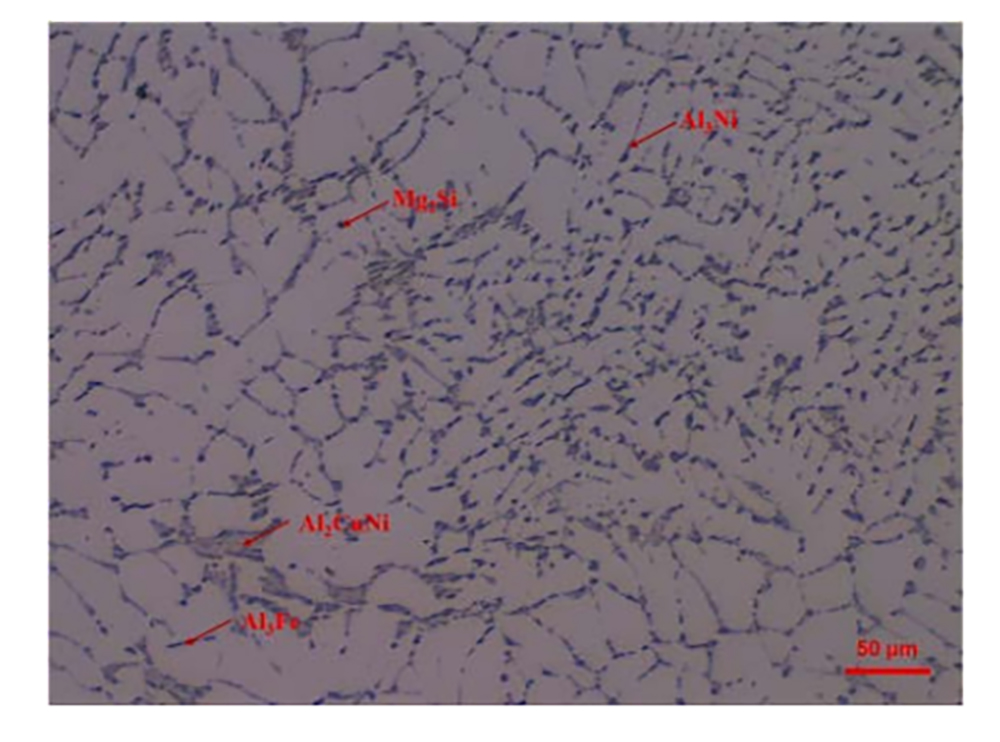

CN119287225B — ALUMINUM ALLOY MATERIAL FOR CAST ALUMINUM ROTOR OF HIGH-ROTATION-SPEED ASYNCHRONOUS MOTOR — Hongjin New Materials Research Nantong Co., Ltd. (China) — The invention discloses an aluminum alloy material for a cast aluminum rotor of a high-rotation-speed asynchronous motor and a preparation method thereof. It solves the problem that the deformation and sweeping of a rotor of the current asynchronous motor cause motor failure under the high-rotation-speed application working condition by designing the mutual combination of elements of Mg/Si/Ca, B/Mn/Ti/V/Cr and Cu/Ni and combining a specific heat treatment process. This reduces the solid solubility in an aluminum matrix, and improves the yield strength by four times compared with pure aluminum under the condition that the conductivity is close to that of pure aluminum.

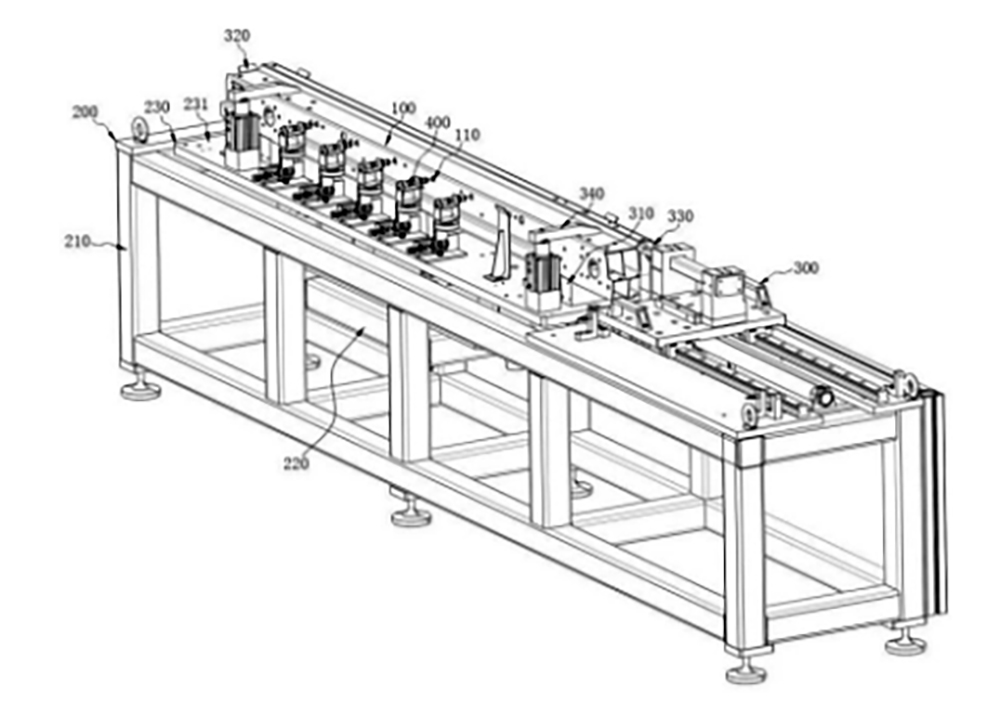

CN119412885B — COOLING DEVICE FOR FORMING AUTOMOBILE ALUMINUM PROFILES — Anhui Guotai Aluminium Co., Ltd. (China) — The application relates to the technical field of aluminum profile forming, and in particular to a cooling and temperature reduction device for the forming of the profile. It comprises a horizontal frame, on which a limiting mechanism for fixing and supporting the automobile aluminum profile and driving the profile to reciprocate, and a cooling and temperature reduction mechanism for cooling the automobile aluminum profile, are installed. The reciprocating frame cooperates with a first support frame and a second support frame through a supporting shaft to drive the automobile aluminum profile to reciprocate, thereby spraying water mist on the surface of the in a relatively short displacement, so that the spray head can quickly complete the spraying and temperature reduction process under the condition of limited displacement of the profile. This effectively reduces the temperature difference before and after the automobile aluminum profile is sprayed, thus reducing the possibility of the profile being flat due to uneven temperature.

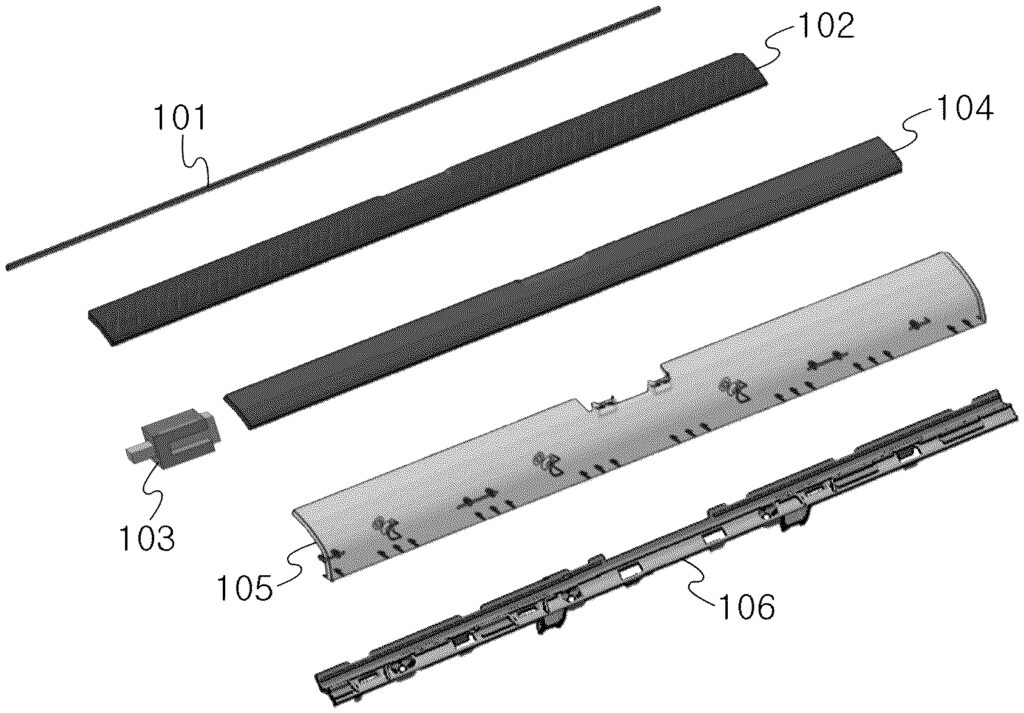

CN118977547B — ALUMINUM ROLL COVER AND PICKUP TRUCK WITH THE SAME — Wenzhou Tianmao Auto Parts Co., Ltd. (China) — The invention discloses an aluminum roll cover and a pick-up truck with the aluminum roll cover, which comprises a front cover, a middle section bar adhesive tape assembly, a tail column, a lock tongue system, a clip system, a guide rail system and a storage box. The front cover is arranged on the upper side of the storage box, the lock tongue system is connected with the front cover, the middle section bar adhesive tape assembly is connected with the storage box, and the tail column is connected with the tail part of the middle section bar adhesive tape assembly. According to the invention, the storage box is arranged so that the middle section adhesive tape assembly can be wound, and the winding cover can be conveniently stored.

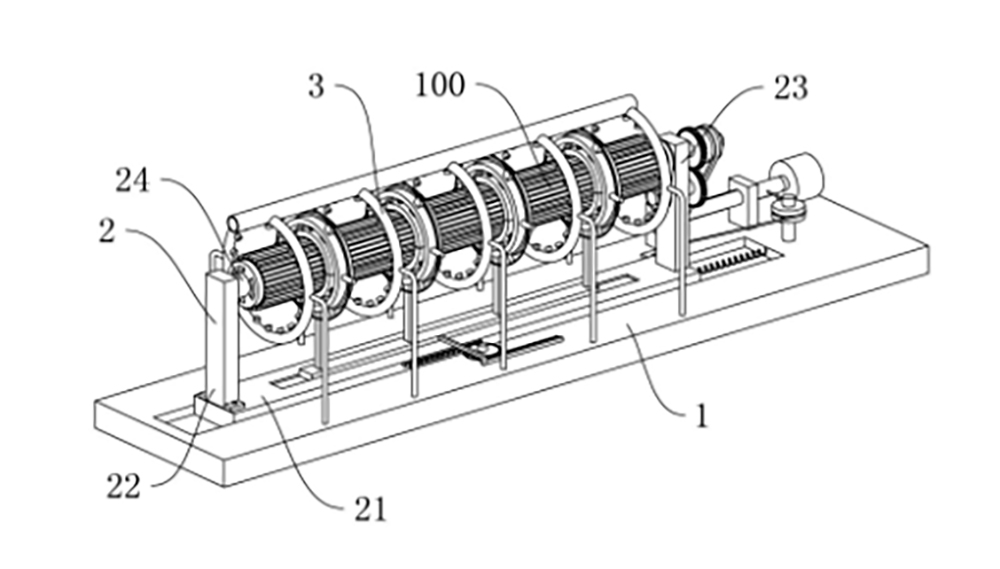

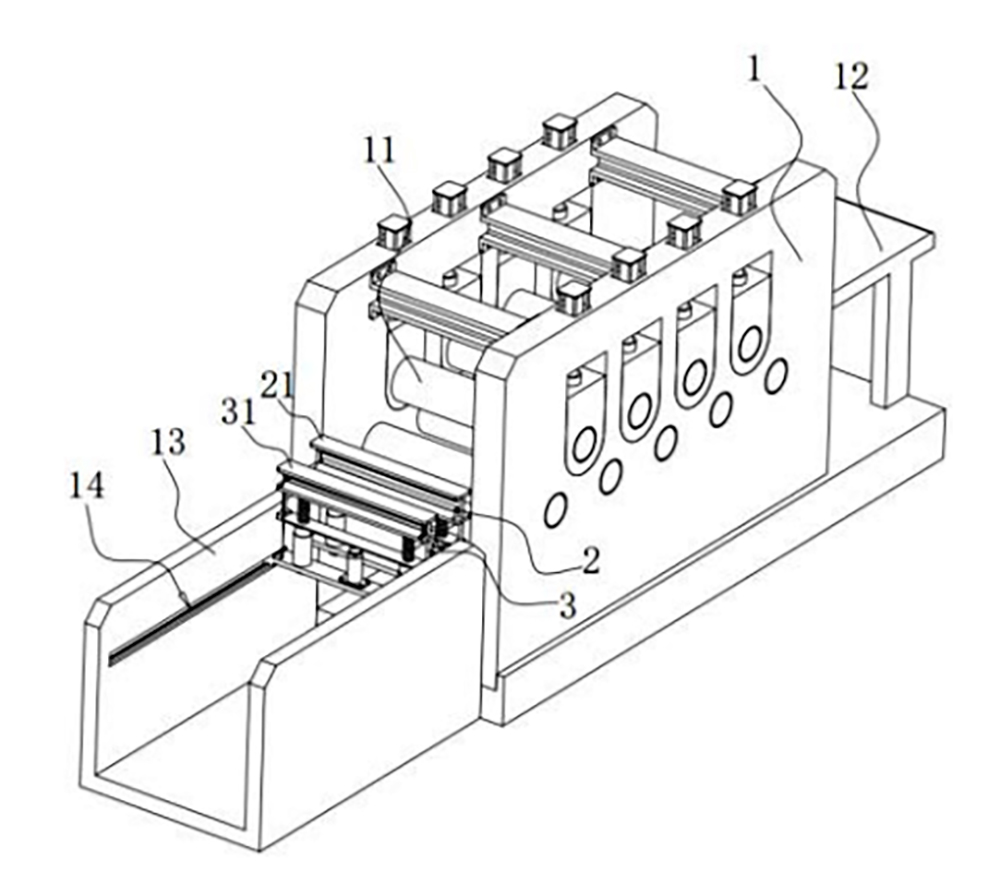

CN119368590B — HIGH-VOLTAGE ALUMINUM BAR STRAIGHTENING DEVICE FOR NEW ENERGY VEHICLES — Guangzhou Xinxing Cables Industry Co., Ltd. (China) — The present application provides a high-voltage aluminum bar straightening device for new energy vehicles, which relates to the technical field of metal aluminum bar straightening, including a straightening machine. A fixed frame is arranged at one end away from the feeding platform. The top end of the fixed frame is connected to a first clamping platform, the first clamping platform is rotatably connected to a first clamping roller, the fixed frame is slidably connected to a second clamping platform, and the second clamping platform is rotatably connected to a second clamping roller. Further, a sliding frame is arranged on the straightening machine, the top end of the sliding frame is fixedly connected to a third clamping platform, the third clamping platform is rotatably connected to a third clamping roller, the sliding frame is slidably connected to a fourth clamping platform, and the fourth clamping platform is rotatably connected to a fourth clamping roller. This invention can reduce the probability of the aluminum bar bending again due to its length after straightening.

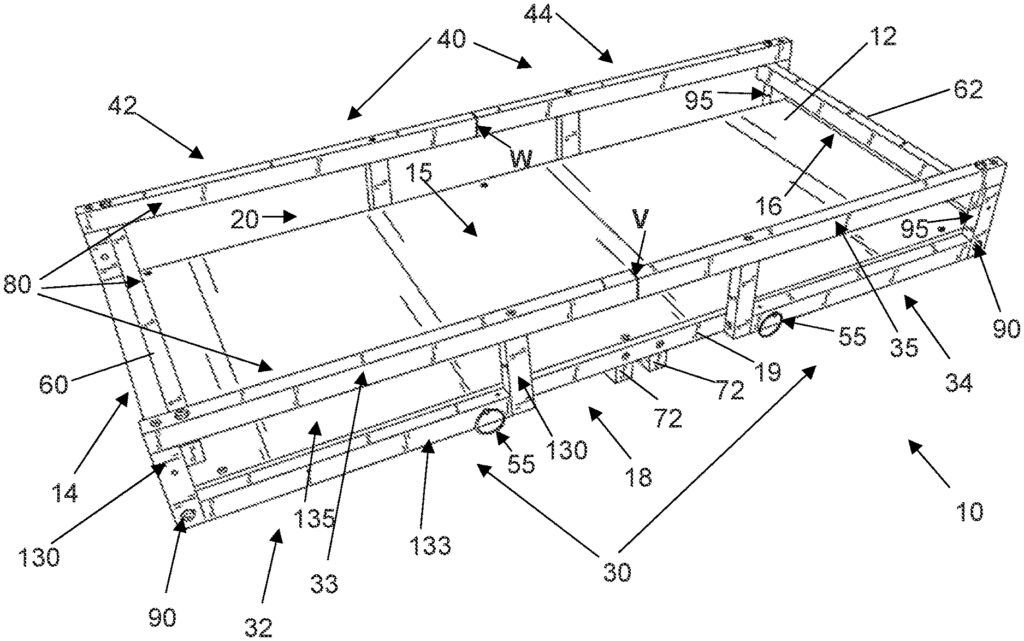

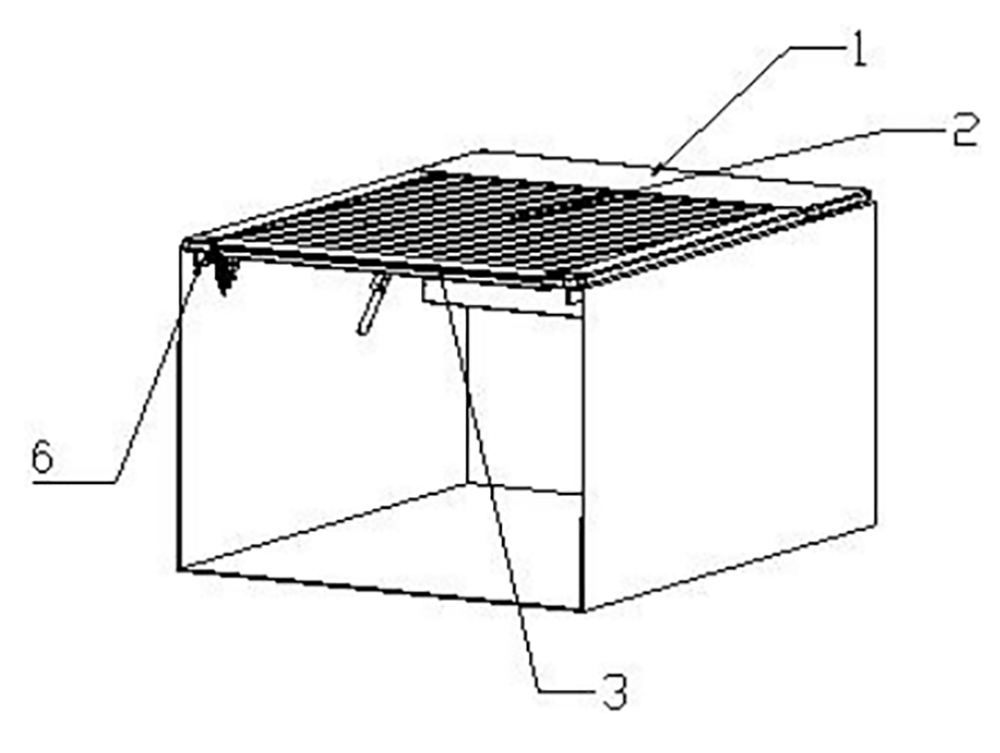

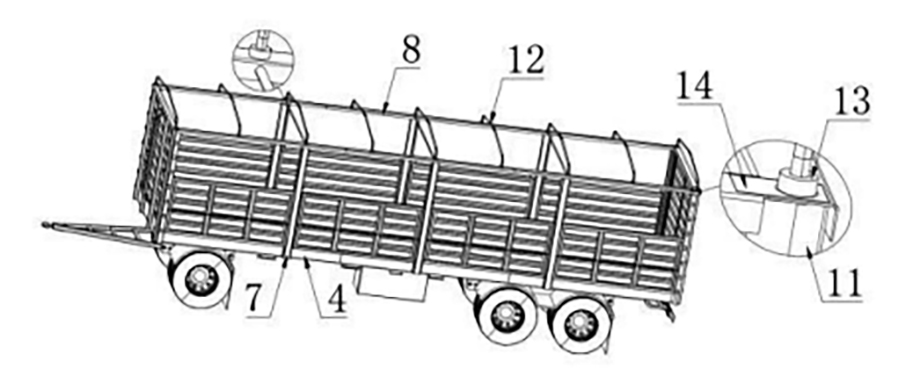

CN118810938B — MODULARIZED ASSEMBLED ALUMINUM ALLOY CARRIAGE — Qingyuan Time Aluminium Co., Ltd. and Guangdong Lingnan Institute of Technology (China) — The invention discloses a modular assembled aluminum alloy carriage – a front carriage, rear carriage, floor frame and two side carriages. Each of the carriages include a floor frame beam located at the bottom, and two adjacent floor frame beams are positioned and clamped by a clamping assembly. Each floor frame beam is installed with a plurality of vertical beam frames, and an upper frame beam is clamped and installed between the corresponding vertical beam frames. A connecting frame is installed between the corresponding two floor frame beams through a strength-increasing member, and the joints between the connecting frame and the floor frame beam and the upper frame beam are connected. The advantages? The aluminum alloy carriage is assembled in a modular manner, which has the advantage of speed, and the two side carriages can quickly form a solid carriage with the front carriage, the rear carriage and the floor frame, which ensures assembly quality while reducing the ability requirements for the assemblers.

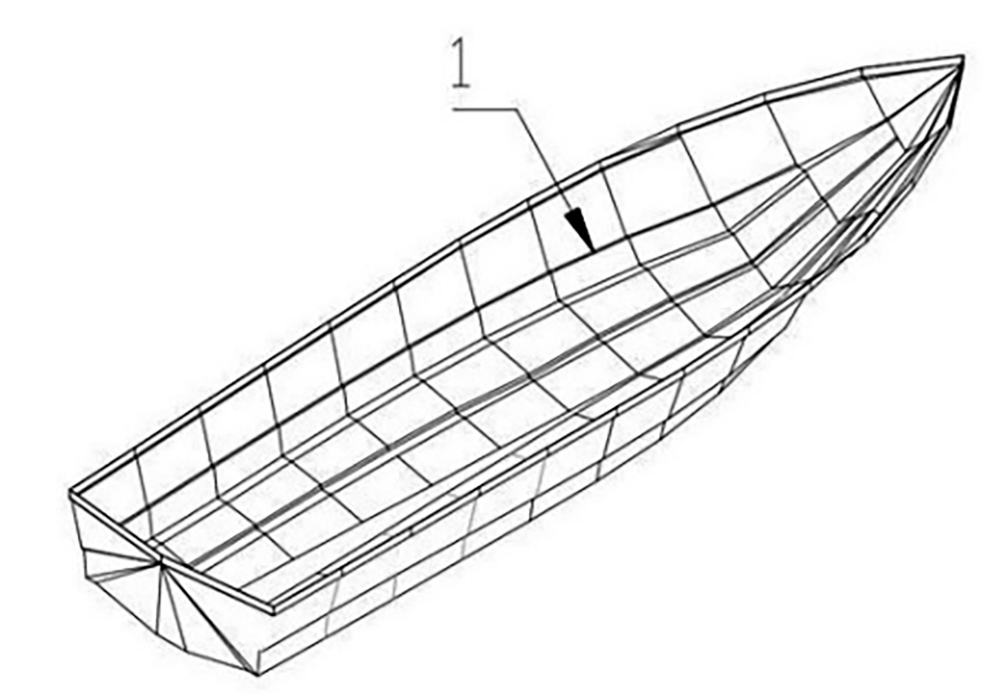

CN118751899B — ALUMINUM ALLOY SHIP BODY COMPRESSION SET DIE FORGING FORMING METHOD — Cui Huaihua (China) — The invention relates to the technical field of aluminum alloy ship body manufacturing, in particular to a method for integrally forming an aluminum alloy ship body with a complex curved surface and an inner rib plate by adopting compression forging. The invention aims to overcome the defects of the prior art by providing an integrated forming method for the compression, coagulation and die forging of the aluminum alloy ship body. This ensures the strength, linearity, water tightness and the integrated forming of the ship shell of the aluminum alloy ship body with complex curved surfaces and inner rib plates, thereby improving the product and simplifying the working procedure.

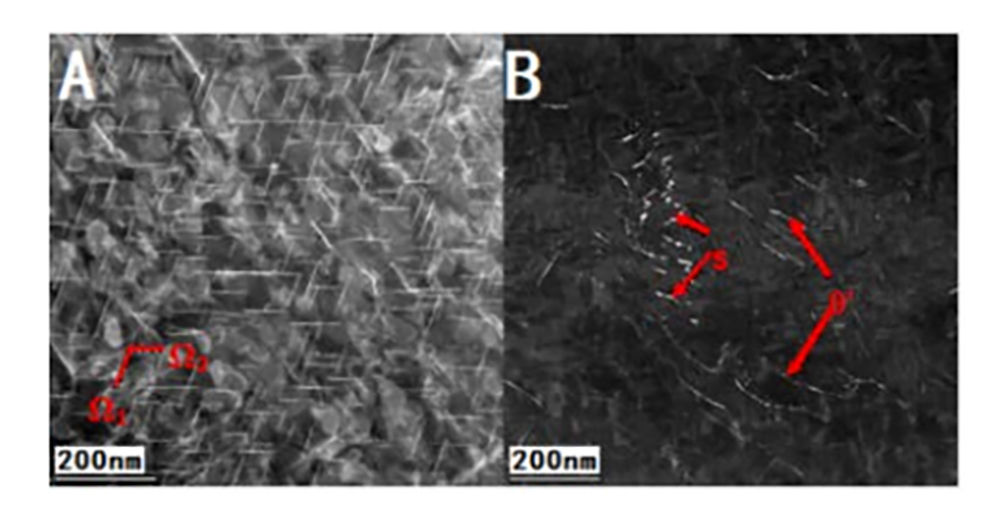

CN118932231B — HIGH-STRENGTH AND DAMAGE-RESISTANT 2XXX SERIES ALUMINUM ALLOYS — Southwest Aluminum Group Co., Ltd. and Chinalco Materials Application Research Institute Co., Ltd. (China) — With the rapid development of the aerospace industry, the comprehensive performance requirements on aircraft structural materials are increasingly strict. These requirements include excellent fatigue damage resistance, corrosion resistance, and heat resistance. In this context, aluminum alloys remain essential in the aerospace field due to their light weight, high strength and good processability. In particular, al-Cu-Mg series aluminum alloys, which are part of the 2xxx series, not only have high specific strength, but also exhibit good heat resistance and high fatigue damage resistance. This invention mainly aims to provide a high-strength damage-resistant 2xxx aluminum alloy, a preparation method and application thereof, and aims to solve the problem that aviation aluminum alloy in the prior art is difficult to have high specific strength and high damage tolerance performance.