“The future cannot be predicted, but futures can be invented.”

— Denis Gabor, nobelist and author of Inventing the Future (1963)

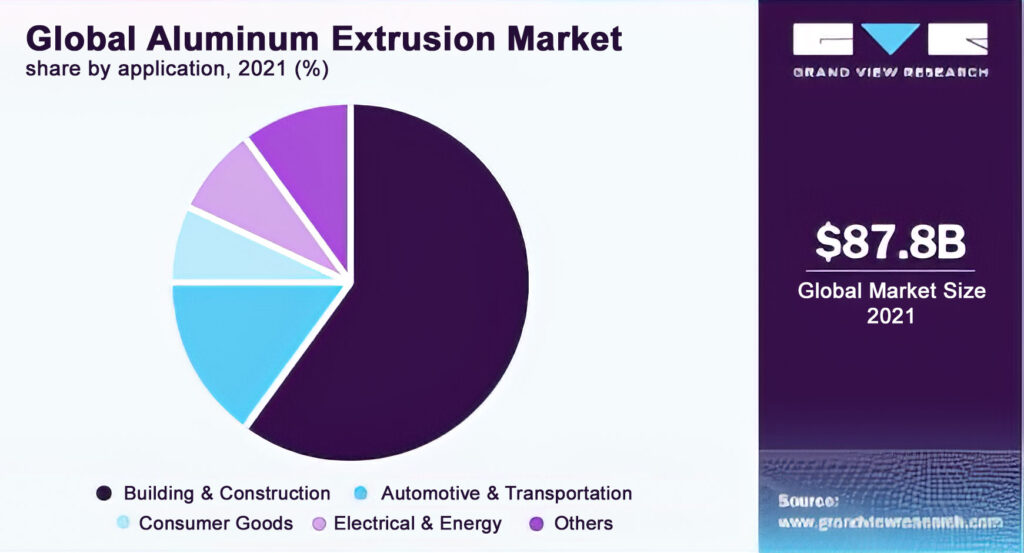

Editor’s Note: As aluminum extrusion applications extend to most business areas, especially for B&C, transportation, industrial, consumer, and defense, it is no wonder that inventions utilizing aluminum extrusions to meet present and future needs of these industries are so varied and creative. Case in point is the selection of patents presented in this issue, all patented in the U.S. within the past year alone and representing a broad assignee base of international companies. These inventions make use of the light weight, special physical and mechanical properties, and sustainable features of a mix of aluminum alloys in a varied range of economical shapes in support of structures throughout the world both functionally and aesthetically. Thus, the global aluminum extrusion market size was US$87.8 billion in 2021 and is expected to grow at a compound annual growth rate of 7.5% from 2022 to 2030 (https://www.grandviewresearch.com/industry-analysis/aluminum-extrusion-market).

In 2021, the U.S. aluminum extrusion market was US$7.3 billion, with the shapes product segment accounting for the maximum revenue share of more than 79.5% over rod & bar and pipe & tube, pointing out how the excellent formability of aluminum alloys in the extrusion process leads to customer value.

However, like analytic geometry, market research in any field depends on assumptions, and these can lead to excellent outcomes—if they are accurate and hold up over time. Considering some of the surprise events of the past two years, particularly the COVID pandemic and Ukraine war, we have to consider the risk of future surprises (or “black swan” events), which may upset the equilibrium of manufacturing industries and affect the aluminum extrusion market—but such instances are hard to predict. Yet, as the selected patents below show and as Denis Gabor has noted, the future can be invented.

— Joseph C. Benedyk, Editor

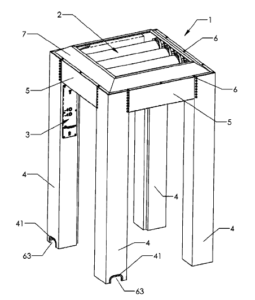

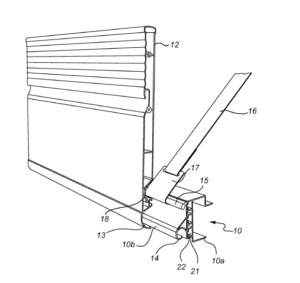

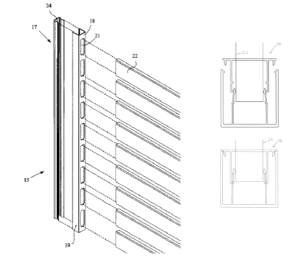

US11560718 — LOUVER ROOF STRUCTURE — Renaissance Patio Products Inc. (USA) — A louver roof system having a simplified assembly and installation methods. The louver roof system is constructed with multi-functional mechanical components by means of pre-molded parts to reduce skilled installation time. Louvers of the roof system each include a louver body defining an integrally formed channel configured to direct water internally from the louver body, through the integrally formed channel of the respective louver, within a frame, and out of the louver roof system when the louvers are in a closed position. The louver body of each of the louvers includes a top surface with an uppermost portion of the top surface that defines, when in the closed position, a non-perpendicular angle relative to the vertical direction such that water is directed to the integrally formed channel of the respective louver Thus, a water drainage path is an integral part of the main structural assembly. The main structure 1 is comprised of 4 (four) posts 4, constructed from aluminum extrusions, arranged vertically in a rectangular pattern, and 4 (four) beams 5, constructed from aluminum extrusions, located coincident to the top surface of the posts.

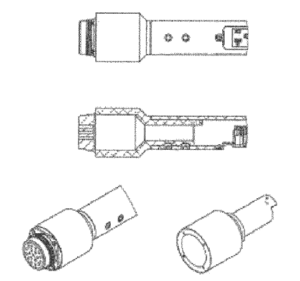

US11555590 — ELECTRICAL CONNECTOR STRIP ADAPTED FOR STRUCTURAL APPLICATIONS — The Light Source, Inc. (USA) — An electrical connector strip is adapted for structural applications in theater, television, and entertainment industries. Connector Strips have been traditionally constructed of fabricated sheet metal or of aluminum extrusions comprising an enclosure body and enclosure cover. The connector strip includes a rigid tubular enclosure defining a hollow continuous internal wireway receiving electrical wiring within an inside diameter of the enclosure and having a substantially uniform outside diameter between opposite ends of the enclosure. At least one outlet pocket is formed in a side wall of the enclosure. A connector adapter plate is located in the outlet pocket and extends within the inside diameter of the enclosure. At least one output connector is carried by the connector adapter plate and resides within the inside diameter of the enclosure with external access provided through the outlet pocket.

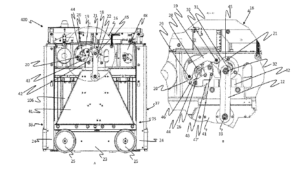

US11553705 — AGRICULTURAL VEHICLE HAVING AN IMPROVED APPLICATION BOOM FOR MOUNTING ATTACHMENTS — CNH Industrial America LLC (USA) — An agricultural vehicle includes a chassis, wheels supporting the chassis for moving the vehicle, an application boom coupled to the chassis and configured to deliver agricultural product to an agricultural field. The application boom has a boom arm including a longitudinal mount. In embodiments, several of which utilize aluminum extrusions, the longitudinal mount includes a first projection, a second multi-lip projection, and a third projection. The second multi-lip projection has a first lip and a second lip. The agricultural vehicle further includes a first mounted attachment fastened to the first projection and the first lip of the second projection, and a second mounted attachment fastened to the second lip of the second projection and the third projection.

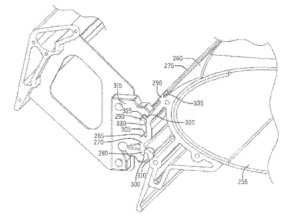

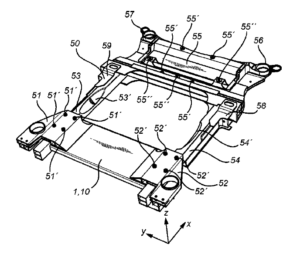

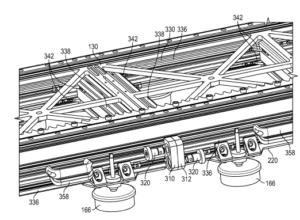

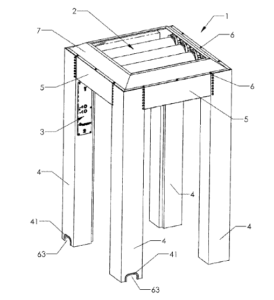

US11548731 — DISPLACEMENT MECHANISM FOR A REMOTELY OPERATED VEHICLE — Autostore Technology AS (Norway) — The present invention relates to a displacement mechanism for a remotely operated vehicle used for automated retrieval of storage containers, the displacement mechanism being for raising and lowering wheels onto a rail system that the remotely operated vehicle runs on. The framework structure comprises a plurality of upright members and optionally a plurality of horizontal members supporting the upright members. The members may be made of extruded aluminum profiles. A displacement mechanism for a remotely operated vehicle includes a motor configured to actuate a drive crank, a coupler link connected to the drive crank on a first side, and a lift rocker on a second side, a displacement link connected to the lift rocker, and a displacement plate connected to the displacement link and having a plurality of wheels provided thereon. The drive crank, the coupler link, the lift rocker, the displacement link, and the displacement plate are each respectively connected with pivot connections such that actuation of the motor actuates the displacement plate between a raised position and a lowered position. The lift rocker is configured with a pivot point arranged in a body of the lift rocker such that the lift rocker, the pivot connection between the displacement link and the lift rocker, and the pivot connection between the lift rocker and the coupler link each rotate around the pivot point when the motor is actuated.

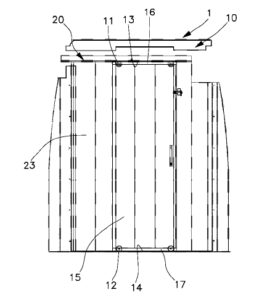

US11548462 — PARTITION WALL FOR COMMERCIAL VEHICLES — GEMA S.R.L. (Italy) — The partition wall for commercial vehicles comprises at least one fixed plate (20) and a sliding door (10) able to slide with respect to said fixed wall (20), predisposed to separate the cockpit of the vehicle from the loading compartment. The sliding door (10) is provided, along the upper edge and along the bottom edge, with a plurality of sliding wheels (11, 12) predisposed to slide respectively on an upper guide (13) and on a lower guide (14) associated with the structure of the vehicle. Preferably, said sliding door is made in modular manner by a plurality of longitudinal members made of aluminum extrusions. The door thus obtained gives excellent mechanical resistance with a low weight. The sliding wheels (11, 12) have a grooved profile predisposed to be coupled with a corresponding rail (19) of said guides (13, 14) having conjugated profile.

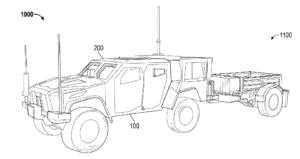

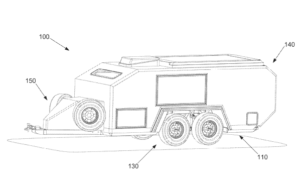

US11541851 — MILITARY VEHICLE — Oshkosh Defense, LLC (USA) — A vehicle includes a passenger capsule having a first end and a second end, a front module coupled to the first end of the passenger capsule and including a front axle assembly, a rear module coupled to the second end of the passenger capsule and including a rear axle assembly, and a braking system. The braking system includes a pump, an actuator including a rod that extends through a brake housing to apply a biasing force to a brake and inhibit movement of the vehicle, and a line coupling the pump to the actuator. Engagement of the pump provides a pressurized fluid flow through the line that overcomes the biasing force and releases the brake. Aluminum castings may be used for various cross member components where the loading is compatible with material properties. Aluminum extrusions may be used to tie and box structures together.

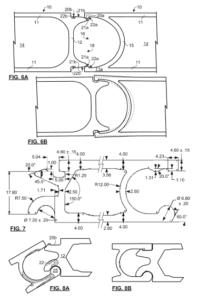

US11541440 — SNAP-FIT EXTRUSIONS FOR FORMING PANELS — National Research Council of Canada (Canada) — Snap-fit connection is desirable for aluminum profiles. A metallic extruded profile has two parallel skins interconnected by a set of at least two webs running between extrusion edges of the profile and snap-fit features on joining edges permitting two instances of the profile to snap fit together along the joining edges, where a first web that is closest to snap-fit features of a first joining edge, is a curved web viewed from the extrusion edges. The curvature allows for both the curved web and skins to participate in snap-fit deformation, allowing for the deformation to be distributed over a large area, for a stiffer snap fit, and reduced plastic deformation.

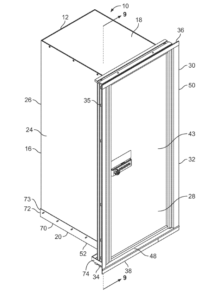

US11529011 — PACKAGE DELIVERY RECEPTACLE AND METHOD OF USE — Florence Corporation (USA) — A system and method of delivering a package to a residence having an address and a locker with a lock is disclosed. The method comprises the steps of, remotely selecting an item from a menu of items provided by a vendor and requesting the item be delivered to the residence, providing the vendor delivery information including the address and the combination code to the lock, shipping the package to the residence, reviewing the combination code associated with the package, opening the locker by manipulating the proper combination on the lock, placing the package in the locker; and closing door of the locker. The locker has an outer frame and door that cooperate to allow any liquid to drain out from the front of the locker and outside the residence and a combination lock that allows for the combination to be easily changed by the resident. In a preferred embodiment, the right vertical frame 32 and left vertical frame 34 are aluminum extrusions of unique shape to enhance the structural integrity of the receptacle as well as its manufacturability. The frame 30 also comprises a top horizontal frame 36 and a bottom horizontal frame 38 also uniquely and complementarily shaped. The top frame 36 and bottom frame 38 may also be constructed of aluminum extrusions.

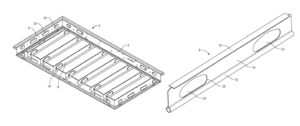

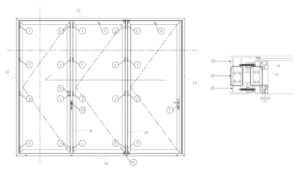

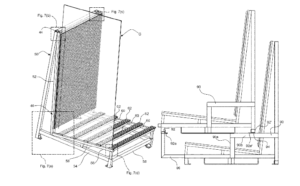

US11519187 — FRAME STRUCTURE FOR A FORMWORK PANEL — Peri AG (Germany) — A support structure for a formwork panel having a support structure and a formwork skin positioned on the front of the support structure and attached to the support structure, wherein the support structure has at least one edge girder on a pair of opposite edges and a plurality of transverse girders between these two edge girders which run transversely to these two edge girders, characterized in that at least some of the transverse girders are designed as a profile girder, comprising a flange at its first end arranged at the front of the support structure, a tubular hollow section at its second end away from the front of the support structure, and between them a preferably wall-like member connecting the first end and the second end. The invention provides for the possibility that the at least one profile girder is an extruded profile made from aluminum. It is possible that the material thickness—seen in the cross-section of the profile girder—is not the same everywhere but can be selected in consideration of a static stress optimization.

US11511807 — ELECTRIC VEHICLE — Volvo Car Corporation (Sweden) — An electric vehicle, including, a user compartment and a front section including a portion of a vehicle chassis, a crash absorbing member located in the front section and connected to the portion of the vehicle chassis, the crash absorbing member including a first extruded profile, preferably an aluminum profile, having a main extension direction in a transverse direction (y) of the vehicle, whereby the extrusion direction of the first extruded profile extends substantially in the transverse direction (y) of the vehicle, and wherein further the first extruded profile includes at least two cells (C1, C2) being defined by outer walls and at least one intermediate wall separating the at least two cells (C1, C2), wherein the at least one intermediate wall has a main extension direction in the transverse direction (y) and a second extension direction which extends substantially in a vertical direction (z).

US11505948 — WALL SYSTEM — mfPHD, LLC (USA) — A monolithic corner and/or adapter panel encapsulates one or more panels while maintaining structural integrity and maintain hygienic properties. The corner may securely receive one or more panels and provide flexibility to easily adjust the one or more panels. The corner and/or adapter panel may simplify installation and an ability to adjust connected panels without compromising safety, installation time, and sterility. A wall system according to embodiments of the present disclosure may include aluminum extrusions. In an embodiment of the present disclosure, these extrusions may be ASTM B221/B221M, with alloy and temper required to suit structural and finish requirements.

US11505198 — VEHICLE TILTING DEVICE, AN ACCESS STATION, A DELIVERY SYSTEM AND A METHOD OF ACCESSING A STORAGE CONTAINER — Autostore Technology AS (Norway) — A vehicle tilting device for tilting a delivery vehicle for increasing access to items from a storage container transported on the delivery vehicle. The vehicle tilting device comprises a base structure and a tiltable platform connected to the base structure, wherein the tiltable platform comprises guiding features adapted to guide the delivery vehicle onto the tiltable platform. The tiltable platform is arranged to be connected to a delivery grid cell of a delivery rail system such that that there is a path to and/or from the tiltable platform for the delivery vehicle via the delivery grid cell. The invention is also related to an access station, a delivery system and a method of accessing a storage container. The framework structure comprises a plurality of upright members and optionally a plurality of horizontal members supporting the upright members. The members may typically be made of metal, e.g. extruded aluminum profiles.

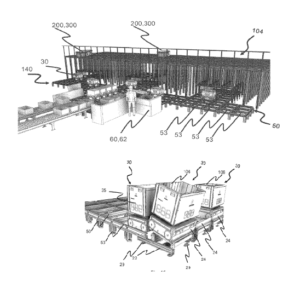

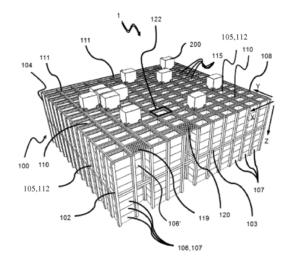

US11498757 — STORAGE SYSTEM — Autostore Technology AS (Norway) — The present invention provides a storage system (1) comprising a storage grid structure (104) having a top rail grid upon which container handling vehicles (200,300) work to store and retrieve storage containers (106) in and from storage columns (105) beneath the top rail grid, wherein the storage system comprises multiple transfer rails (110′,111′) forming a horizontal transfer rail grid (5) arranged at a level below the top rail grid, at least one transport vehicle (19) operating on the transfer rail grid, a picking/stocking station (8) for picking/stocking items between a storage container (106) and a packaging box (24), and an unloading/loading assembly (23) for unloading/loading packaging boxes containing such items, the transport vehicle (19) is arranged to move upon the transfer rail grid (5) in two perpendicular directions and comprises a carrier platform (20), wherein the transfer rail grid is arranged to allow access for the transport vehicle (19) to transport one or more packaging boxes at a time between the picking/stocking station and the unloading/loading assembly (23). The framework structure 100 defines a storage grid 104 comprising a plurality of upright members 102 and optionally a plurality of horizontal members 103 supporting the upright members 102. The members 102, 103 may typically be made of extruded aluminum profiles.

US11493834 — MODULAR TRACK SYSTEM FOR CINEMATOGRAPHY ROBOT AND MOTION CONTROL SYSTEMS — Motorized Precision LLC (USA) — A modular track and dolly system for cinematography includes a set of detachable, human-portable track sections, each including a unitary rigid frame supporting first and second spaced apart guide rails and having at least at least one connection plate at each longitudinal end of the frame providing a precise joint interface surface for aligning adjacent track sections. The rigid frame may include a pair of longitudinally extending chords connected by perpendicular struts and two or more web members extending at an oblique angle relative to the chords and struts. Each track section may also include a lightweight subframe made up of an assembly of longitudinal members and connected lateral stringers, with the rigid frame being supported on and attached to the subframe. A dolly for carrying a cinematography robot is guided by the guide rails and may include a motor-driven pinion that engages a rack on the track. In a presently preferred embodiment, the subframe 330 of each track section 200 is preferably assembled from two primary longitudinal members 336 and three lateral stringers 338 all being segments of rectangular 80 mm×80 mm of extruded aluminum T-slot framing profile material, joined together by corner brackets 342 and threaded fasteners.

US11485273 — ATTACHMENT OF CARGO HOLDING BELT TO A VEHICLE LOADING PLATFORM — Axel Johnson International ABA (Sweden) — A loading platform configured for attachment of cargo holding belts by means of a hook, the platform comprising a substantially rectangular frame supporting a loading surface, the frame including two longitudinal side members, and platform walls attached to outer sides of the frame members, inner surfaces of the platform walls delimiting a generally flat loading area. On a side facing away from the loading area each side member is provided with a protruding edge for engaging a hook of a cargo holding belt, wherein the edge extends beyond the loading area, and is received by a recess in a platform wall. Side members are preferably made of aluminum profiles with desired cross-section, relatively easy to manufacture at low cost, and are available from commercial suppliers. The loading platform has a frame of structural members, e.g., extruded aluminum profiles.

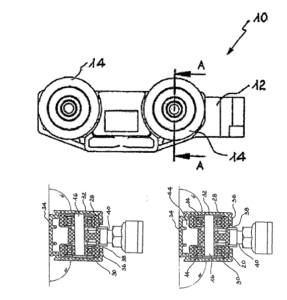

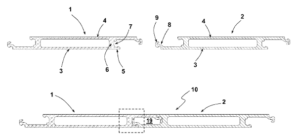

US11479999 — CARRIAGE WITH ELASTIC COMPENSATION ELEMENTS FOR MOVING SLIDING DOORS — Terno Scorrevoli S.P.A. Unipersonale (Italy) — The purpose of the present invention is to provide a carriage for sliding doors able to effectively and completely compensate for problems related to possible irregularities existing along the sliding seat of extruded aluminum profiles, thereby avoiding the resulting noise phenomena and the occurrence of vibrations, squeaking and the like during the movement of the individual carriages. A carriage (10) provided with one or more pairs of wheels (14) for moving sliding door (42) is arranged in a sliding seat (44) of an extruded profile (28), made of aluminum and fixed to a wall (48) or ceiling (54). The extruded profile in which the carriage (10) is arranged comprises opposite side walls (30, 32), oriented orthogonally with respect to the upper base (34) and with respect to the lower base (36) of said profile; on said lower base a central slot (38) extending longitudinally is made for the passage of a stem (40) projecting downwards in the direction of the door (42) to which it is connected. The carriage (10) comprises a support body (12) made of plastic, metal, or other suitable material, constituting the load-bearing frame of said carriage to which the pairs of wheels (14) are connected, with rivets (16); each of the wheels is paired with an elastic element (20) placed in a recess (24) made along the opposite sides of the support body (12).

US11473311 — LOUVER ROOF STRUCTURE — Renaissance Patio Products Inc. (USA) — The present invention relates generally to the field of patio roofs, and more particularly, easy to assemble and disassemble freestanding louver roofs. The louver roof system is constructed with multi-functional mechanical components by means of pre-molded parts to reduce skilled installation time. Water drainage path is an integral part of the main structural assembly. The main structure 1 is comprised of 4 (four) posts 4, constructed from aluminum extrusions, arranged vertically in a rectangular pattern, and 4 (four) beams 5, constructed from aluminum extrusions, located coincident to the top surface of the posts. The 4 (four) posts 4 are attached to the 4 (four) horizontal beams 5 by means of a plurality of self-tapping screws 6. This forms a rigid box structure if lower posts are connected to a ground substrate.

US11472246 — TOWABLE VEHICLE — Bruder IP Pty. Ltd. (Australia) — A towable vehicle including a chassis, at least two wheels and a suspension assembly supporting each wheel. The suspension assembly includes a swing arm pivotally mounted to the chassis, an axle mounted proximate an end of the swing arm, the wheel being mounted on the axle, at least one shock absorber extending from the chassis to the swing arm, an airbag swing arm mounting pivotally coupled to the swing arm, an airbag chassis mounting coupled to the chassis, an airbag coupled to the airbag swing arm and airbag chassis mountings so that inflation of the airbag allows a suspension height to be adjusted over an operating range and a pivot arm pivotally mounted to the chassis and the airbag swing arm mounting to maintain an orientation of the airbag swing arm mounting over the operating range. In one embodiment the joining plates are formed from aluminum extrusions.

US11448003 — STRENGTHENED AUTOMATIC SLIDING DOOR — Assa Abloy Entrance Systems AB (Sweden) — Disclosed is a vertical profile for an automated sliding door. The profile is formed by front and rear walls connected by nose and tail walls. The nose and tail walls are thicker than the front and rear walls to provide enhanced resistance to deflection in the through-door direction. The walls are formed as an aluminum extrusion. The arrangement and thickness of the walls provides strength sufficient to withstand high wind loads without the installation of reinforcing members. Fillets may be provided where the walls are joined to lessen the tendency for the nose and tail walls deflect, further strengthen the profile. To reduce manufacturing costs and to provide a light-weight structure, the sliding door frame is usually constructed from aluminum extrusions. By using extrusions, a manufacturer can inventory a stock of standard material that is cut to lengths required to produce doors with specific dimensions.

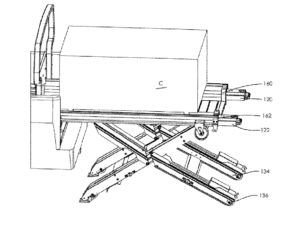

US11440752 — VEHICLE LOADING SYSTEM — Masterhaul LLC (USA) — A loading/unloading system for an associated truck bed includes first and second laterally spaced rails configured for re) receipt in the associated truck bed. First and second support leg assemblies are operatively associated with the first and second rails, respectively. First and second motors are received on the first and second leg assemblies, respectively, and are configured to selectively raise and lower the first and second rails. A sensor assembly is mounted on the rails to monitor the position of the first rail relative to the second rail. The sensor assembly is interconnected to the first and second motors for maintaining the rails at the same height relative to one another. Legs and rails are aluminum extrusions. The application deck/bin rail aluminum extrusions have channels for the floor panels to slide into, to create a weld free, bolt free, all aluminum assembly.

US11434679 — FOLDING DOOR STRUCTURE — Cyber Top Trading Limited (Hong Kong) — A folding door structure is provided. The folding door structure includes an upright column, upper sliding bracket and a lower sliding bracket. The upright column is hinged to the door leaves. Preferably, the upright column is of a thermal-break aluminum profile structure including an outer cavity, a middle cavity and an inner cavity, and the first latch is mounted in the middle cavity. The thermal-break aluminum profile includes an inner aluminum profile 23, a heat insulating bar 24 and an outer aluminum profile 25. The heat insulating bar 24 is located between the inner aluminum profile 23 and the outer aluminum profile 25 to form a three-cavity structure. The inner aluminum profile 23 and the outer aluminum profile 25 can realize different colors of indoor and outdoor aluminum profiles or can realize the uniformity of the color of the external wall and the indoor decoration. The folding door structure further includes a first lock component. The first lock component includes a first latch mounted inside the upright column, and both ends of which are extended out from the top and bottom of the upright column to insert into the upper slide and/or the lower slide. By providing a first lock component and an upright column, a first latch can lock the position of the upright column relative to a door frame in a direction of wind pressure. Accordingly, the stress environment of the upper sliding bracket and the lower sliding bracket is improved, and the reliability and the resistance to high wind pressure of the connection mounting structure between adjacent door leaves are improved.

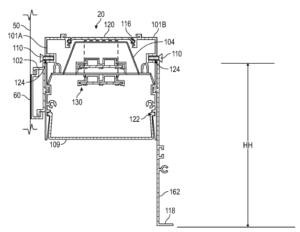

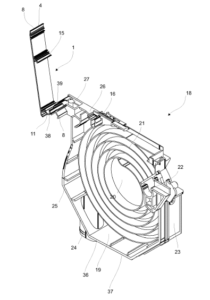

US11384923 — TELESCOPING PERIMETER LIGHTING FIXTURE AND INSTALLATION METHODS — Gammalux Systems, Inc. (USA) — A lighting fixture includes a mounting rail slidably attached to a first side of a main section. A lighting assembly includes a first LED board attached to the main section, and a second LED board attached to an extension movable longitudinally relative to the main section. The extension may be attached to the mounting rail and be slidable longitudinally relative to the main section, to extend the length of the lighting fixture. The second LED board may be supported on a slider extrusion rigidly attached to a spacer on the main section. The lighting fixture can be more quickly and easily installed with minimal field cutting of components. The top 120, the first side 101A, the second side 101B, the mounting rail 102, and the drop flange elements may be provided as aluminum extrusions. In this case, the extrusions may have features to facilitate assembly or attachment of the fixture components.

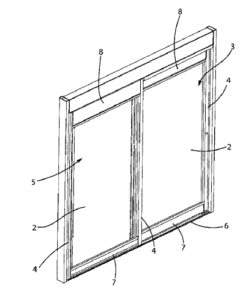

US11384592 — FRAME FOR MANUFACTURING LARGE-SURFACE DOORS OR WINDOWS — BBG S.A. (Portugal) — A frame system for a door or window is constituted by at least one fixed frame (1) and at least one movable sash (3) mounted in the fixed frame and having a central post (5) and a handle (4). The locking system (6) for the sash (3) is integrated in the aluminum profiles of the fixed frame (1). The sash (3) has no visible aluminum profiles next to the floor and next to the ceiling. The thickness of the visible aluminum of the post and of the handle ranges from 1 mm to 5 mm and the central post (5) and the handle (4) can be mounted to either side of the movable sash without modification. At the heights near the post (5) and the handle (4) only 1-5 mm of aluminum is visible. The profiles of the post have a thermal break.

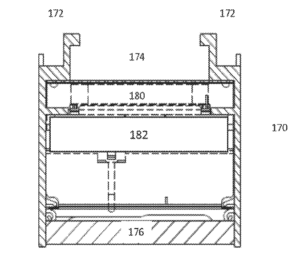

US11378583 — AUTOMATED CLINICAL ANALYZER SYSTEM AND METHOD — Siemens Healthcare Diagnostics Inc. (USA) — An analyzer system for in vitro diagnostics includes a sample handler module having a robot arm that delivers samples from drawers into carriers on a linear synchronous motor automation track. In vitro diagnostics (IVD) allows labs to assist in the diagnosis of disease based on assays performed on patient fluid samples. Samples are delivered via the automation track to individual track sections associated with individual analyzer modules. Analyzer modules aspirate sample portions directly from the sample carriers and perform analysis thereon. In some embodiments, rails 172 are aluminum extrusions that also include vertical sides on the exterior of the track components underneath track surface 174. These aluminum extrusions can include brackets to easily bolt internal components to these side pieces to form a track unit.

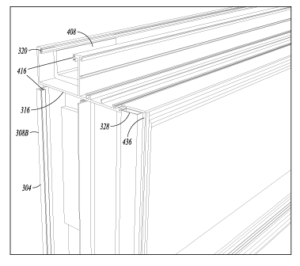

US11376934 — LID ARRANGEMENT FOR A CANISTER FOR A ROLLUP TRUCK BED COVER — Mountain Top Industries APS (Denmark) — A lid arrangement for a canister for a rollup truck bed cover comprises a lid and a canister. The canister has a main housing part and opposite housing end parts. The lid spans between said housing end parts across the main housing part, and the lid is pivotally connected to at least one of the housing end parts. The pivotal lid need not be taken fully off the canister when access is needed to the main housing part, e.g., to inspect the drain(s) or wipe up water inside the canister. The canister parts can be polymeric parts or metal parts. The housing end parts, the lid profile and the main housing part profile can for example be molded parts of a durable weather resistant plastic material or be made of lightweight metal such as aluminum. The profiles for the lid and the main housing part can be extruded parts or lengths, such as polymer profiles or aluminum profiles. The main housing part can also be made of metal plate material that is cut to size and bend to appropriate shape.

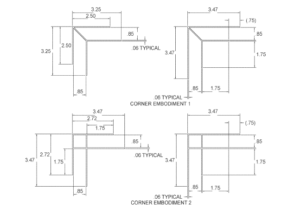

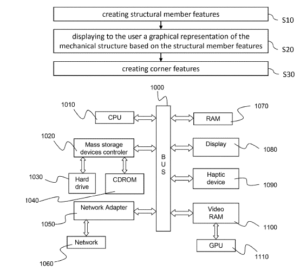

US11373015 — DESIGNING A 3D MODELED OBJECT REPRESENTING A MECHANICAL STRUCTURE — Dassault Systemes Solidworks Corporation (USA) — The invention notably relates to a computer-implemented method for designing a 3D modeled object by interaction of a user with a feature-based CAD system, the 3D modeled object representing a mechanical structure. The method comprises creating structural member features, each structural member feature representing a respective structural member of the mechanical structure and displaying to the user a graphical representation of the mechanical structure based on the structural member features. The method further comprises creating corner features, each corner feature representing a respective corner of the mechanical structure, the creation of the corner features being performed automatically by the system, the corner features being editable by the user. This provides improved ergonomics for structural design. Examples of metal structures which may be represented by the 3D modeled object designed by the method include: a machine frame, the structural members being for example bars forming the mechanical frame of a machine, the machine being any type of machine such as a measurement and/or production machine, a structural system based on one or more aluminum extrusion profiles, the structural members being for example aluminum extrusions, the corners being for example achieved with bolted joints. A welded structure, the corners being for example achieved with weld joints between structural members which may be bars, or a vehicle structure, the structural members forming for example the supporting frame of a vehicle, e.g. which may be any type of vehicle, for example a terrestrial vehicle such as a car or a truck, a water vehicle such as a boat or a ship, an air vehicle such as an airplane or a helicopter.

US11365070 — STORAGE RACK FOR GLASS ARTICLES — Guardian Glass, LLC (USA) — A storage rack is provided for storing glass sheets. The rack includes substantially horizontal and vertical portions. The substantially horizontal and/or vertical portion(s) of the rack include(s) one or more flexible supports, each including at least one channel. Arms are attached to the left and right sides of the rack. The rear legs have tabs attached thereto, with lower lips extending away from the rack. The rack is stackable with another rack, e.g., with the upper rack’s rear sitting on the lower rack’s arms, and with the upper rack’s front supported by a support member extending upwardly from tubing provided in the lower rack that is accommodated in holes/recesses of the upper rack. The arms are sized, shaped, and arranged to reduce the likelihood of tipping of the upper rack, and the tabs help mitigate the effect of side-to-side movement of the upper rack relative to the lower rack. The vertical portion of the rack includes end pieces 44, which may be aluminum extrusions connected to a backer 46 of plywood or the like. It will be appreciated that one or more backers 46 may be provided. Similarly, it will be appreciated that one or more end pieces 44 may be provided (e.g., multiple pieces may be provided for the top and bottom and left and right areas, a single piece may be provided, etc.).

US11345980 — RECYCLED ALUMINUM ALLOYS FROM MANUFACTURING SCRAP WITH COSMETIC APPEAL — Apple Inc. (USA) — The disclosure is directed to recycled aluminum alloys and processes for recycling aluminum alloy scrap with cosmetic appeal and applications including enclosures for electronic devices. Conventional recycling of manufacturing chip scrap (e.g., 6063 Al) is generally associated with downgraded quality. In order to maintain the quality of the recycled product, conventional recycling of manufacturing chip scrap may be limited to a particular source and a limited amount of scrap in the recycled material. The disclosure provides an aluminum alloy which may include iron (Fe) of at least 0.10 wt. %, silicon (Si) of at least 0.35 wt. %, and magnesium (Mg) of at least 0.45 wt. %, manganese (Mn) in amount of at least 0.005 wt. %, and additional elements, the remaining wt. % being Al and incidental impurities. The disclosed recycled 6000 series aluminum alloys allow use of recycled materials, such as manufacturing scrap from various sources. The disclosed recycled 6000 series aluminum alloys result in significant reduction of the carbon footprint associated with manufacturing.

US11339814 — PROFILE ASSEMBLY — Otto Fuchs Kommanditgesellschaft (Germany) — A profile assembly having a first profile and having a second profile connected on its long side to the first profile, which two profiles each have a hook strip integrally formed on the long side, wherein the hook projection of the hook strip of the first profile points in the one direction, and the hook projection of the hook strip of the second profile points in the opposite direction, the hook strips brought into engagement with one another in a claw-like manner. The first profile has an anchoring channel following its longitudinal extent, and the hook strip of the second profile has a clamping strip which is integrally formed thereon, which hook strip is secured by its hook projection and its clamping strip in the anchoring channel of the other profile by a cold joining connection. In order to produce the cold joining connection, one of the two hook strips comprises an adjusting strip which is formed by a cold joining process and which is supported in the produced profile assembly by its free end face while being under prestress. The hook strip secured in the anchoring channel is placed under prestress within the anchoring channel, at two points situated opposite one another in the direction of the height of the profile assembly, with respect to the adjoining portions of the first profile due to the cold joining connection.

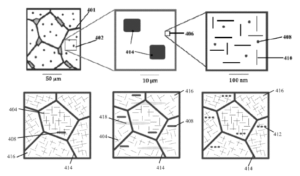

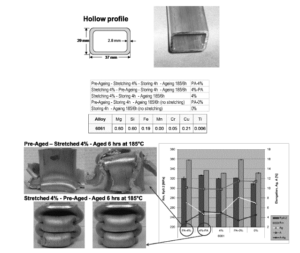

US11313019 — METHOD FOR PRODUCING A HEAT TREATABLE ALUMINUM ALLOY WITH IMPROVED MECHANICAL PROPERTIES — Norsk Hydro ASA (Norway) — Method for producing structural components from heat treatable aluminum alloys based on extruded material, in particular AA 6xxx series alloys, the components having improved crush properties and being particular applicable in crash zones of vehicles, such as longitudinals and crash boxes, the method including the following steps: a. casting a billet from said alloy by DC casting, b. homogenizing the cast billet, c. forming a profile from the billet by extrusion, preferably a hollow section d. optionally, separate solution heat treatment, e. quenching the profile down to room temperature after the forming step and the possible separate solutionizing step, f. stretching the extruded or the separate solutionized profile to obtain at least 1.5% plastic deformation, g. artificially ageing the profile.

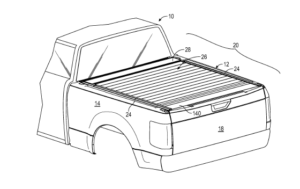

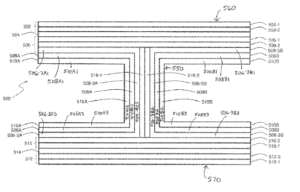

US11318826 — STACKING RIGID COVER — BOS Automotive Products, Inc. (USA) — A retractable cover system includes laterally spaced apart guide rails that each provide a track on either side of an opening. The retractable cover system further includes a cover that has multiple slats that are configured to interlock with one another in a deployed configuration. The slats are slidable in the tracks between first and second positions within the opening. The slats are stacked onto one another in a stowed configuration. The slats include laterally extending profiles that are complementary to one another and are configured to interlock with one another in a deployed configuration. The complementary profiles are configured to decouple from one another in the stowed configuration. The cover system 20 includes a frame about the truck bed opening provided by laterally spaced apart guide rails 24, which may be provided by, for example, aluminum extrusions of various possible shapes. The guide rails 24 define a path alone which the cover 26 moves and are secured to the lateral sides 14 of the truck bed 12. The cover 26, or hard tonneau cover, which may be constructed from multiple interlocking slats 30, is supported by and can slide along tracks 22 within the guide rails 24.

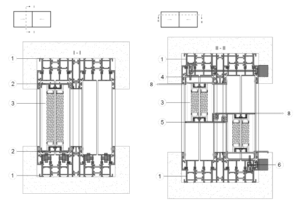

US11313122 — UNITIZED CURTAINWALL SYSTEMS AND METHODS — New Hudson Facades, LLC (USA) — This document discusses, among other things, unitized curtain systems and methods related to the fabrication and installation of curtainwalls. A curtainwall unit may comprise a frame including a horizontal gutter, a horizontal sill, a first vertical mullion between a first end of the horizontal gutter and a second end of the horizontal sill, and a second vertical mullion between a second end of the horizontal gutter and a second end of the horizontal sill. The horizontal gutter may include a rear channel extending across the horizontal gutter, and at least one protected horizontal channel at least partially beneath the rear channel, the rear channel having at least one opening to the at least one horizontal gutter. Each vertical mullion may include a protected vertical chamber having an opening to the at least one protected horizontal channel. The perimeter framing members of a unitized system may be designed with gaskets and male/female mating aluminum extrusions which, when fitted together, create an air and water barrier between the interior and exterior without the use of wet sealants between adjacent curtainwall units.

US11273622 — STIFFENING ELEMENTS THAT COMPRISE INTEGRAL CURRENT FLOWPATHS — The Boeing Company (USA) — A stiffening element that includes one or more integral current flowpaths may include: a first layer including carbon-fiber-reinforced thermoplastic plies; a second layer including one or more glass-fiber-reinforced thermoplastic plies; and/or a third layer including aluminum. The third layer may form an outer surface of the stiffening element. The third layer may form at least part of the one or more integral current flowpaths. A method of using a stiffening element that comprises one or more integral current flowpaths as part of a current return network for a stiffened structure may include: selecting the stiffening element that includes a first layer including carbon-fiber-reinforced thermoplastic plies, a second layer including one or more glass-fiber-reinforced thermoplastic plies, and/or a third layer including aluminum; and/or routing current from the current return network (CRN) through the one or more integral current flowpaths of the selected stiffening element. Portion of such CRNs may be fabricated, for example, with aluminum extrusions. Such aluminum extrusions may be made with non-structural-grade aluminum having relatively low resistivity values, as opposed to relatively higher resistivity values often associated with structural-grade aluminum.

US11268294— SNAP FIT POSTS FOR FENCE PANELS BALUSTRADES AND THE LIKE — SAS Systems Australia PTY LTD (Australia) — The present invention is directed extruded aluminum members which are comprised of parts that snap fit together without requiring any screws or rivets. Such members can be used in the construction of assemblies such as post and rail fences, fence panels and balustrades and the like to improve ease of manufacture and installation. A post for a fit together panel comprising at least one said post and at least one slat, the post comprising a base member and a cover member, the cover member comprising a pair of sidewalls and an interconnecting end wall, the interconnecting end wall containing a plurality of openings through which the end of a slat can pass, the sidewalls adapted for extension over the channel member, the base member comprising a base wall and opposed sidewalls, at least one sidewall comprising a clamping leg adapted for clamping engagement against the end of a said slat passing through a said opening in the cover member, and snap fitting means on the channel member and/or the cover member to enable the channel member and the cover member to be snap fitted together.

US11220299 — MODULAR LOADING PLATFORM FOR A VEHICLE — Axel Johnson International AB (Sweden) — A modular loading platform for a vehicle, comprising a frame composed of a plurality of interconnected aluminum extruded frame members, wherein the members are each provided with at least two parallel grooves extending along the members and facing away from the frame. The platform further includes a set of mounting elements having parallel protrusions which have been inserted into engagement with said parallel grooves in one of the members. The mounting elements form a structure on which additional parts of the loading platform may be mounted.