The Aluminum Association just released the 2017 Molten Metal Incident Report covering calendar year 2016. The report highlights the predominant hazards that result in explosions during molten aluminum management worldwide, incorporating roughly 300 aluminum plants in 20 countries. Though not a statistical representation of the industry due to the fact that incidents are voluntarily reported, this tracking nonetheless is an important marker to highlight the hazards in working with molten aluminum and motivate a greater awareness of safety in the workplace.

Incidents and Injuries by Industry/Operation

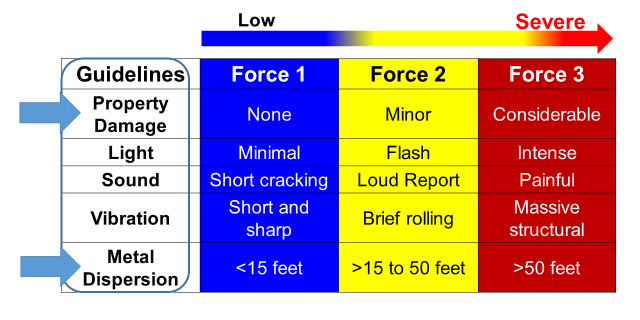

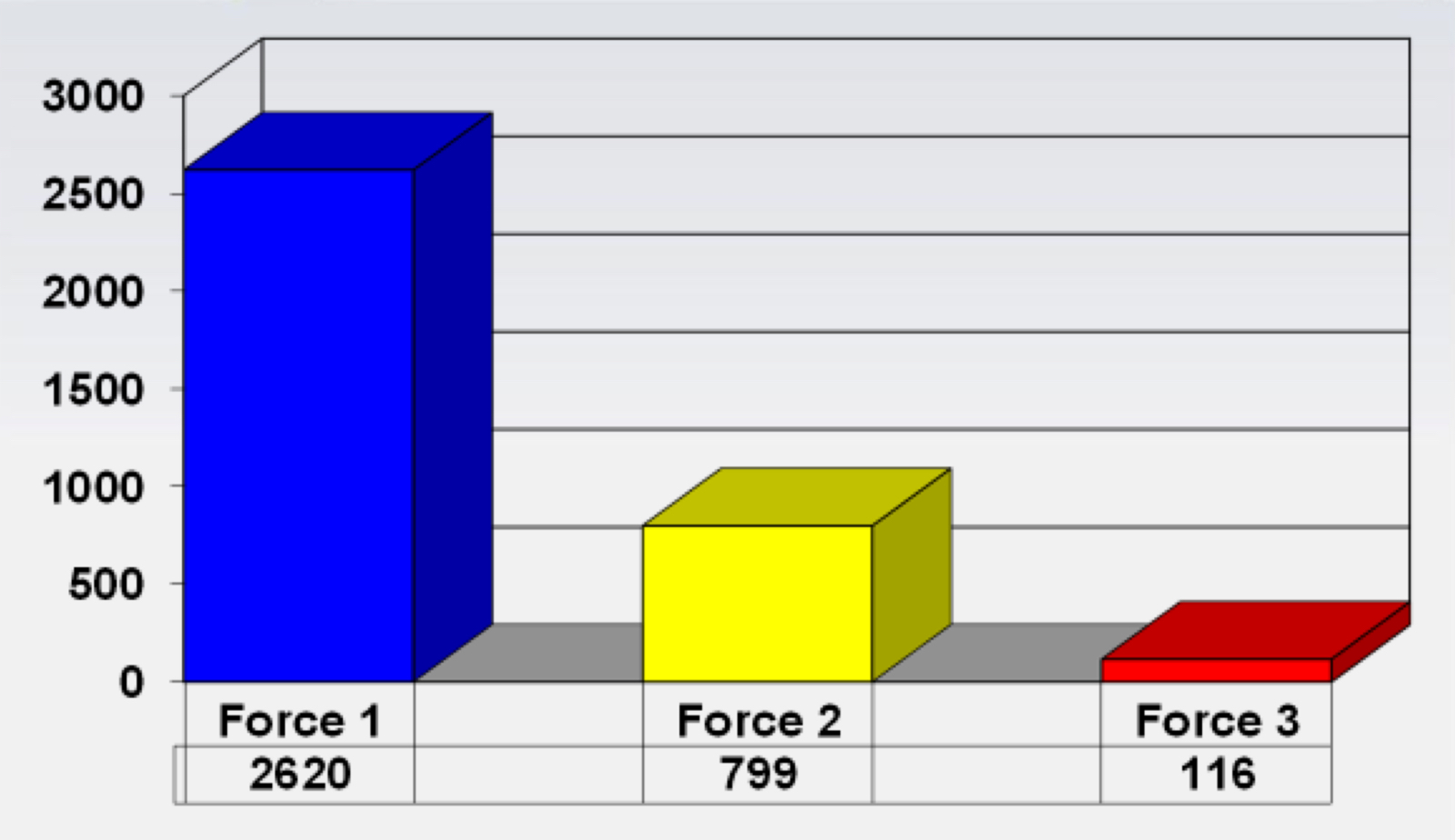

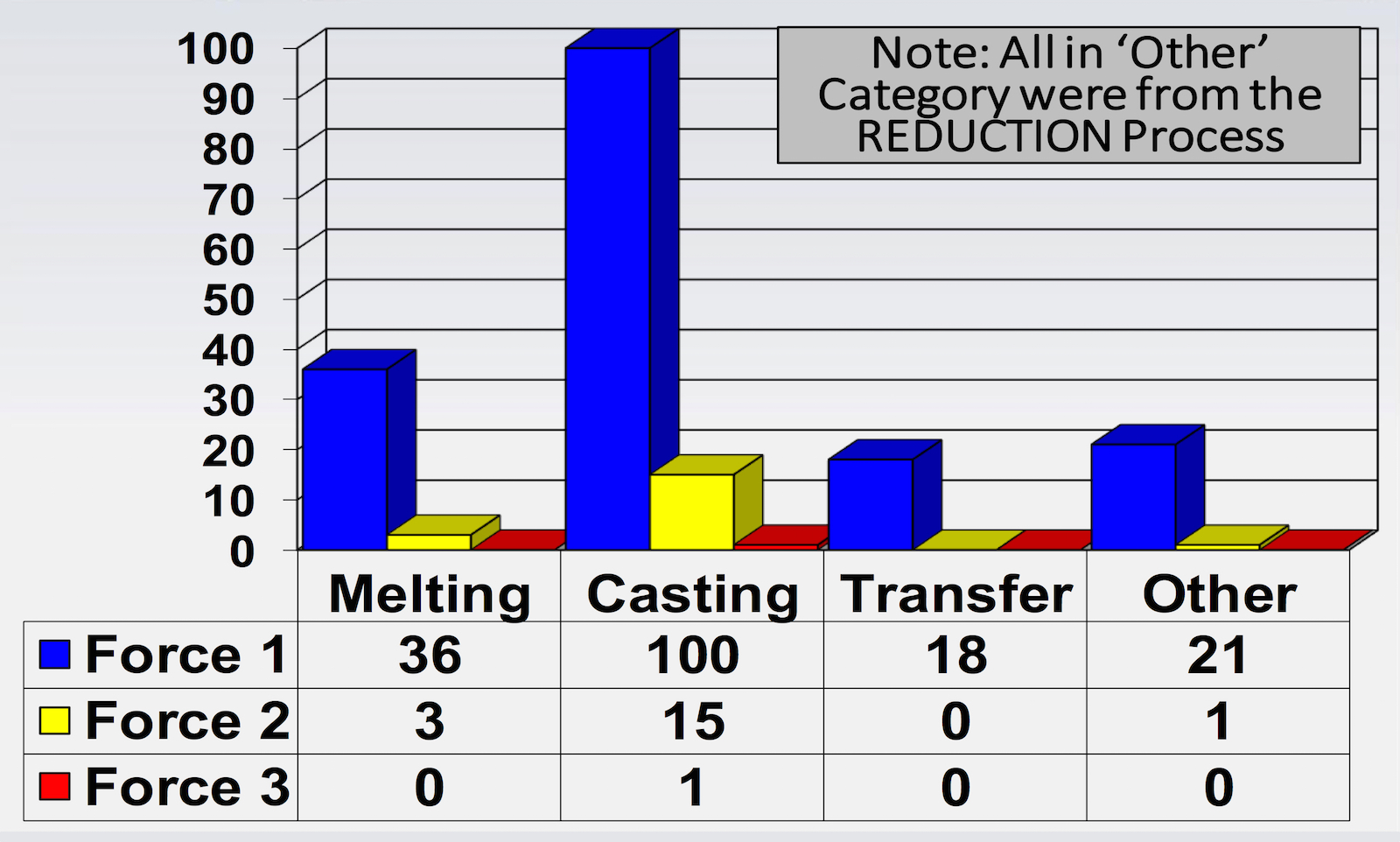

In 2016, there were 195 incidents reported including a record high number of 176 Force 1 incidents. There were 18 Force 2 explosions and one Force 3 explosion. The differences in force explosions from least to most severe is shown in Figure 1. In 2016 there were 18 injuries reported with 11 being minor and seven serious, and with no fatalities. There were 3,535 total incidents reported from 1981-2016 with the preponderance being Force 1 type (Figure 2). Since 1981, the melting operation has accounted for the highest number of fatalities, and also the highest number of Force 3 explosions. It should also be noted that since 1981 a significant number of injuries have occurred in transfer operations with seven fatalities occurring even from this typically straightforward procedure.

Incidents by Industry Operation:

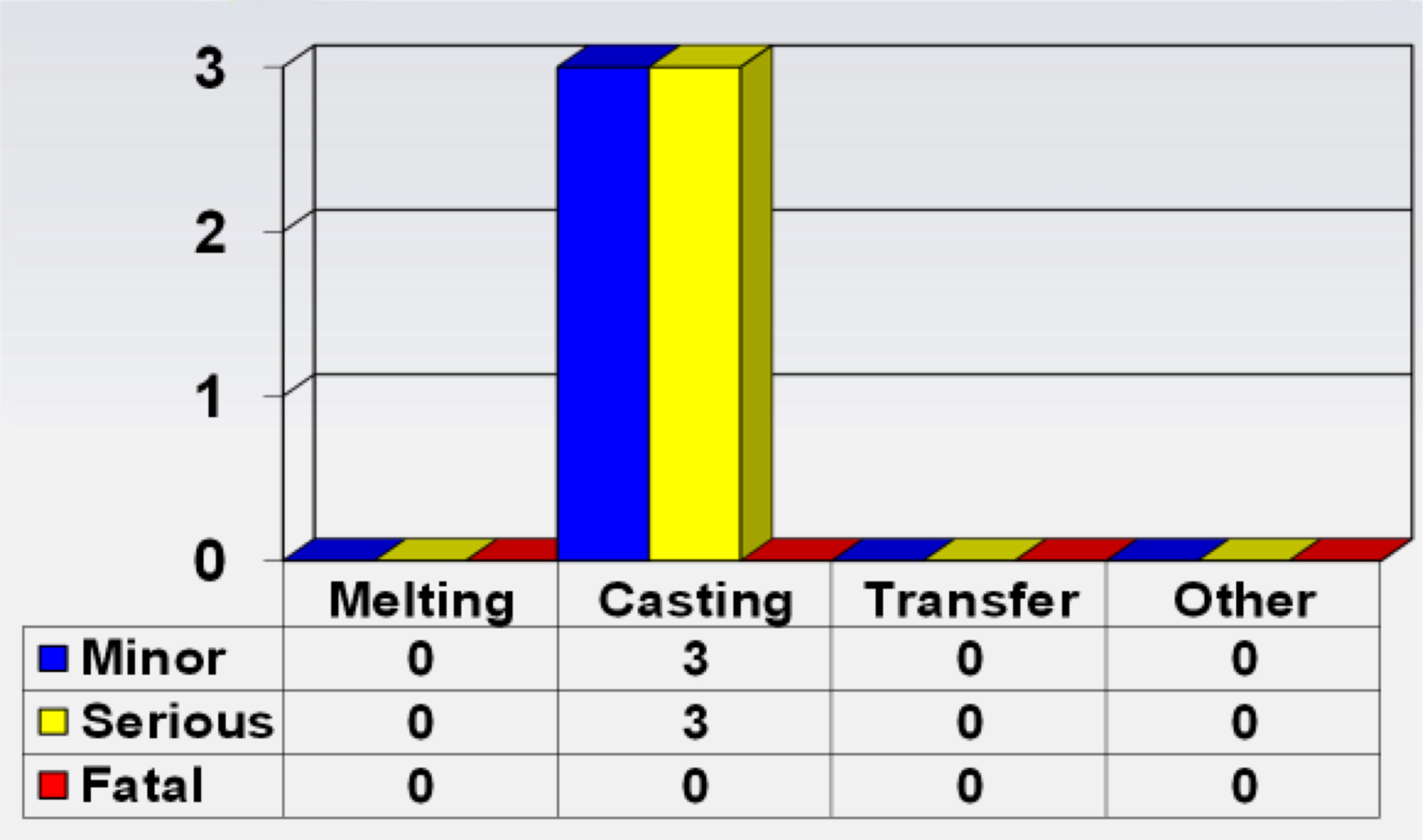

All of the seven serious injuries reported in 2016 occurred during the DC casting process. Six of the seven serious injuries involved drain pan explosions when the cast was being terminated. The other serious injury also occurred at the end of a cast when the molten ingot head was lowered below the mold. In 2016, most of the explosions occurred in the casting area, 100 Force 1, 15 Force 2, and one Force 3, followed by the melting area, which had 36 Force 1, three Force 2, and zero Force 3 (Figure 3). The melting operation accounts for the highest number of fatalities, also the highest number of Force 3 explosions. It should be note that a significant number of injuries have occurred in transfer operations with seven fatalities occurring even from this typically rather straight-forward procedure. Four minor injuries were reported in the other category in 2016, all in the reduction process.

Incidents by Process Plant:

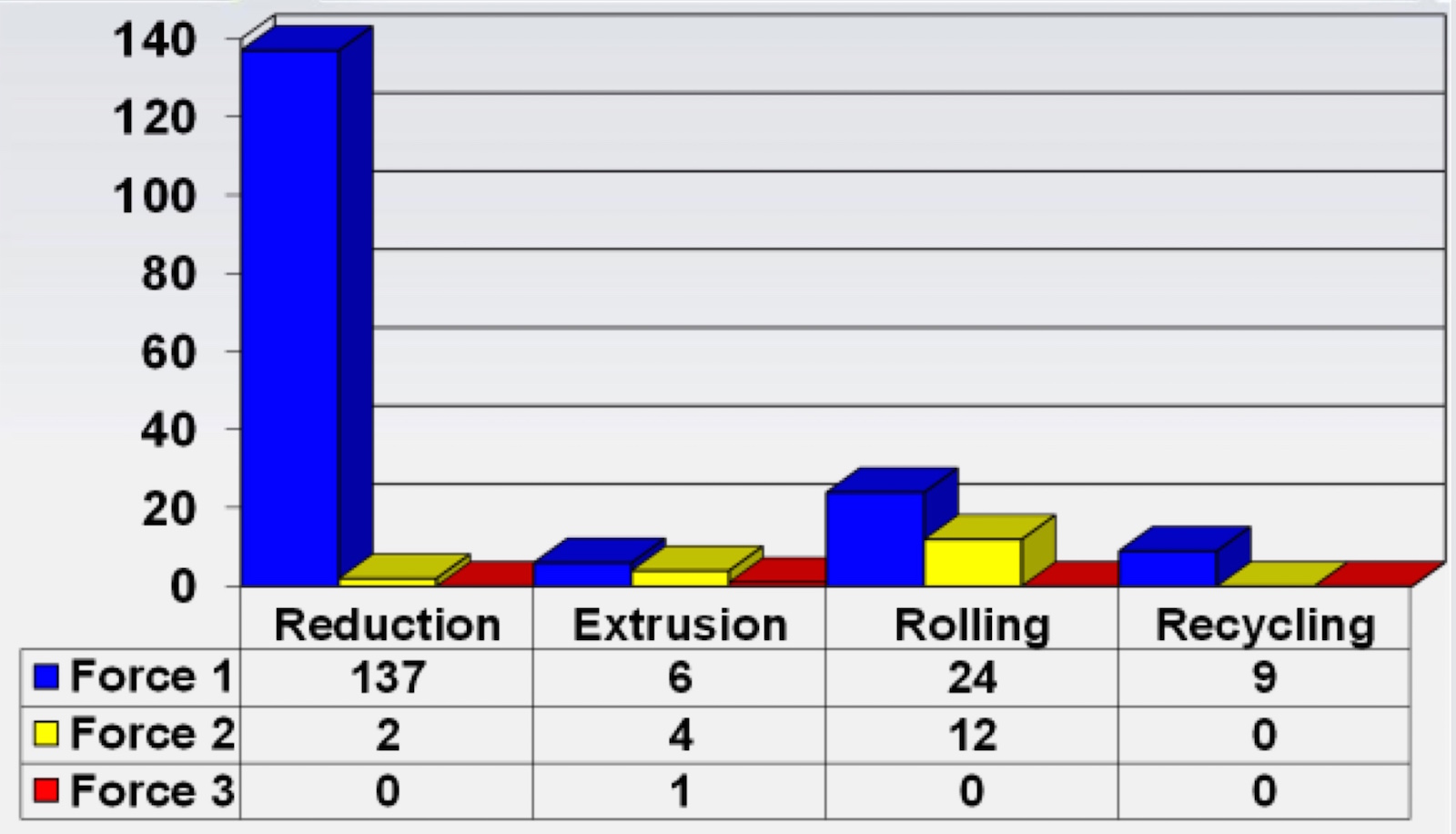

Incident data versus the type of process plant (reduction, extrusion, rolling, and recycling) for 2016 is shown in Figure 4. A majority of the explosions reported during that period occurred in reduction facilities, the second highest were reported from rolling facilities. Three minor and three serious injuries occurred in rolling (Figure 5). Three serious and two minor injuries occurred in extrusion. These five were all related to one incident.

Commitment to Safety

The Aluminum Association has made the safety and well-being of aluminum industry workers a top priority. The association believes the reported incidents can be minimized or eliminated entirely by careful attention to safe handling practices and the sharing of best practices. To that end their safety programs include: the development and distribution of guidelines on the safe production and handling of aluminum, Casthouse Safety Workshops to educate plant workers and managers on workplace safety, and ongoing testing and reporting involving member companies for continued safety improvements.

Editor’s Note: A copy of the 2017 Molten Metal Incident Report as well as a Molten Metal Incident Reporting Form is available by download from the Aluminum Association at: www.aluminum.org/resources/electrical-faqs-and-handbooks/safety.

This article first appeared in the December 2017 issue of Light Metal Age. To read more articles from this issue, please subscribe.