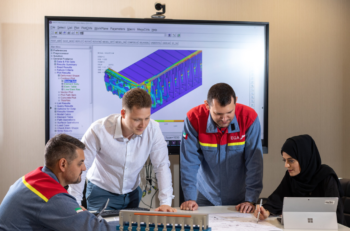

Emirates Global Aluminium (EGA) completed the design phase of its EX reduction cells, the company’s next generation smelting technology. “Technology development has been a foundation of our global competitiveness for decades,” said Abdulnasser Bin Kalban, chief executive officer of EGA. “EX technology will enable the production of more aluminum with less energy and lower emissions, […]