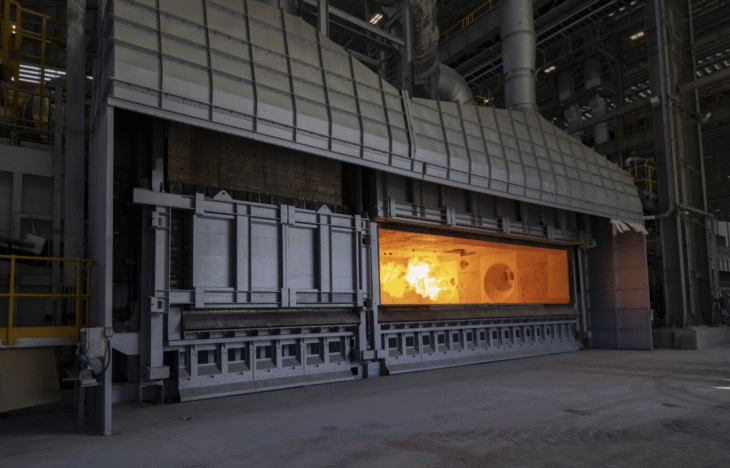

Emirates Global Aluminium (EGA) achieved a major milestone in the construction of its aluminum recycling plant under construction at Al Taweelah. The giant melting furnace at the plant has been charged with scrap metal for the first time.

“Aluminum’s infinite recyclability is a key reason our metal is an essential material for the development of a more sustainable society,” said Abdulnasser Bin Kalban, chief executive officer of EGA. “We are now reaching the final stages of construction on this important project, which will turn aluminum scrap generated in the UAE and elsewhere into new high quality aluminium products that make modern life possible.”

The Al Taweelah recycling plant, which started construction in 2023, will have a production capacity of 185,000 tonnes per year, making it the UAE’s largest recycling facility. The new plant will process both post-consumer and pre-consumer aluminum scrap, which will be blended with primary aluminum into low-carbon, high-quality billet and T-bars.

Commissioning of scrap sorting equipment began in December. The recycling plant’s scrap sorting system can shred and segregate up to 150,000 tonnes of scrap per year, using magnetic, mechanical and x-ray segregation technology.

The Al Taweelah recycling plant is also equipped with a 90,000 tonne per year melting furnace, which operates at around 750°C. The melting furnace uses heat regeneration burners to further improve efficiency. Liquid recycled metal is transferred from the melting furnace to two 90 tonne capacity holding furnaces, which are used to blend recycled metal with primary aluminum from EGA’s smelter and to adjust the metal chemistry.

On site work continues to complete the casting and homogenization stations to produce finished recycled aluminum products. Construction is expected to be completed by the end of the first quarter of 2026.

Additional Recycling Investments

EGA Leichtmetall, a European specialty foundry in Germany, was acquired in 2024. In December, EGA announced its plans to expand production at EGA Leichtmetall more than six-fold by building a second facility near the existing Hannover location. The project will add 110,000 tonnes per year of scrap sorting capacity and 150,000 tonnes per year of melting and casting capacity, with first hot metal expected in 2028.

EGA acquired 80% of EGA Spectro Alloys in the U.S. in 2004. The first phase of an expansion was completed in 2025 and a second phase is expected to be completed during 2027, taking EGA Spectro Alloys’ capacity to 200,000 tonnes per year. Recently, the company placed an order with Presezzi Extrusion for the supply of key equipment for the project.

EGA markets aluminum with recycled content under the product brand RevivAL. The company also blends recycled metal with primary aluminum produced using solar power, marketed as CelestiAL-R, and with nuclear power, sold as MinimAL-R.