Kobe Steel and FANUC Corporation jointly developed an experimental robotic welding system to join dissimilar metals — such as aluminum and high strength steel — amid the growing trend toward multi-material applications aimed at utilizing the optimal material for the most appropriate use. The companies plan to present the system to automakers in order to commercialize it for practical use.

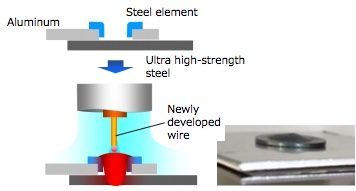

Welding of different metals has not been easy in the past due to the build up of intermetallic compounds and galvanic corrosion, so the typical method has been various forms of mechanical joining (rivets, fasteners, adhesive bonding, etc.). In order to combat this challenge, Kobe Steel developed the element arc spot welding (EASW) process, which joins dissimilar metals like aluminum and high strength steel using a mixture of inexpensive arc welding and rivets (called elements).

In the EASW process an aluminum plate with pre-drilled holes is overlapped with a solid steel plate. A hollow steel rivet is then inserted into the aluminum hole, followed by a welding wire that is liquified using arc welding to form a strong joint between the aluminum and steel plates. The process is able to provide a strong, flat joint without liquid metal embrittlement (LME) crack generation.

For aluminum materials, the process is applicable to sheets of 5000 and 6000 series alloys, typically used for automotive components. It can also be used for high strength extruded products of 7000 series and die castings (forged materials) with relatively thick gauge.

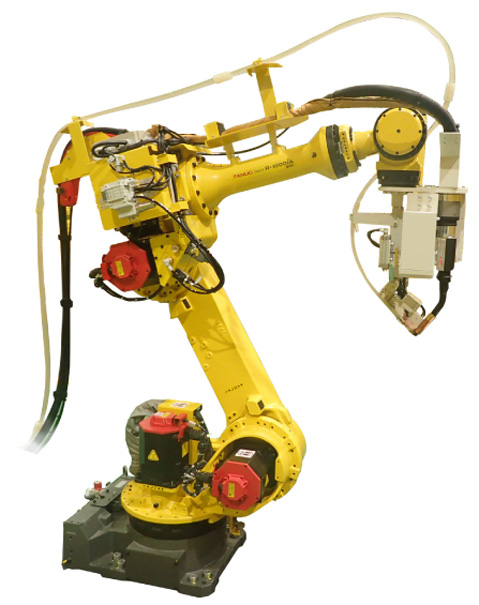

In order to apply this process in the automotive industry, the development of robotic systems for easy use in assembly lines was necessary. FANUC implemented its knowledge in robotics, engineering, and sensor technologies to automate the EASW process at high speeds. Specifically, the system performs a series of actions at high speeds, including position detection, smooth and accurate movement of the robot, pressurization, feed and engagement of the rivets, and arc welding.

A prototype of the EASW robot system has shown the highest joint strength compared with conventional joining methods.