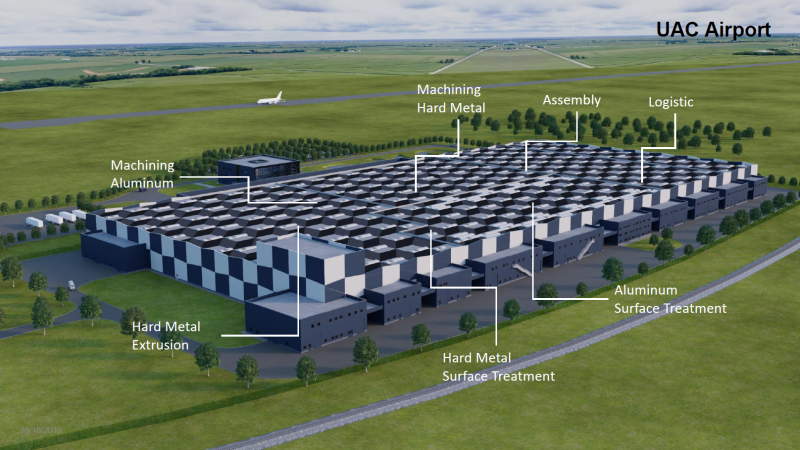

Universal Alloy Corporation (UAC), a supplier of of hard alloy extrusions, is expanding its capacity through the construction of a new facility in Baia Mare, Romania, near the local airport. It will produce extruded aluminum tubes and titanium profiles for the aerospace industry. This unique location will enable UAC not only to supply the assembled products, but also to carry out service and maintenance for airplanes, directly at the airport, thus extending the value-added chain.

As part of the aerospace division of the Swiss-Austrian industrial group Montana Tech Components AG, UAC is certified according to strict NADCAP, AS9100, ISO, and PART 21 POA standards. The expansion project in Romania is in response to demand from the company’s key customers, such as Airbus, Boeing, and Bombardier, among others.

New Induction Furnace

For its new operation, UAC ordered an induction furnace with an overhead cross conveyor from Otto Junker in Germany. The furnace is able to behave like a single-phase mains energy connection, which means that there is no phase shift leading to temperature drops between the individual coils. In addition, each sub-coil of the inductive billet heating can be controlled so that a particularly fine temperature gradient can be achieved. The division of furnace into several independently controllable zones ensures an optimum temperature gradient for isothermal extrusion. By using a particularly short, low-maintenance field extender, the furnace can flexibly process various billet lengths. Due to the optimal symmetry, the cosφ = 0.99 and the avoidance of any voltage peaks, better conditions for the energy supplier are also possible. The IGBT electrical converter further optimizes the heating process and improves grid stability.

In addition to providing high temperature tolerance, flexibility, and reliability, the induction furnace features an energy saving design, in which a ceramic protection tube is used instead of a conventional stainless steel protection tube. This also extends the service life of the furnace as it does not store any heat.

The furnace and all auxiliary equipment are scheduled to be commissioned, with support from an Otto Junker specialist, in early 2020.