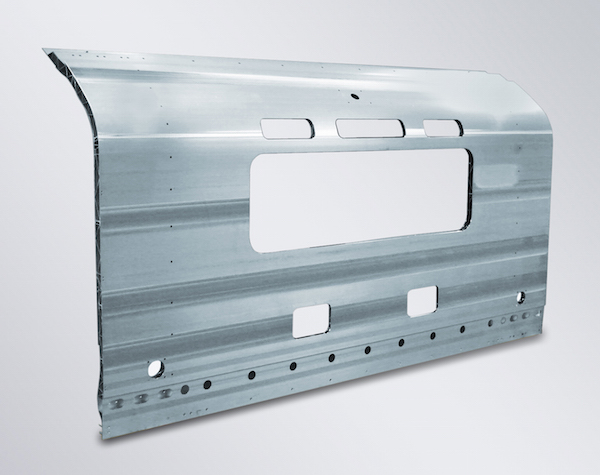

Steel and aluminum are the dominant materials used in the construction of train bodies, including applications such as the train sideboards, roof and floor panels, and cant rails, which connect the floor of the train to the side wall. Aluminum provides a number of benefits to high-speed train car bodies, including its light weight and its uniform and smooth surface (no “waves” in the metal, as with steel, which means less finishing work after assembly). Furthermore, assembly can be performed in a modular fashion that is more cost effective due to parts reduction, compared with the many smaller and heavier components as with steel.

A train comprised of lightweight aluminum cars uses less energy to operate – to move – than a heavier train, and it is easier to start and stop, helping total journey time, according to Sven Lundin, market sector director for Sapa. “With our metallurgical expertise and knowledge, we helped the industry begin substituting with aluminum and we keep our customers ahead, for example, with local application engineers involved in the early design phases of customer projects,” says Lundin. “With this kind of participation, we can help reduce customer costs by 10-to-15%, partly by optimizing the weight of designs.”

Expanded Manufacturing for Rail Profiles

In order to meet demand for larger and thinner-walled aluminum products in the rail industry, Sapa is investing in new production lines at sites in Belgium and Sweden.

At its plant in Lichtervelde, Belgium, the company is increasing the force of the large aluminum extrusion press from 6,500 to 8,200 tonnes. The added power will enable the company to extrude 6xxx-series profiles that are up to 620 mm wide and up to 26 m long, with an extremely thin wall thickness down to 1.6 m — thus reducing the amount of aluminum used in the section, further lightening an already weight-saving solution without sacrificing strength. The upgraded press will begin series production in January 2017.

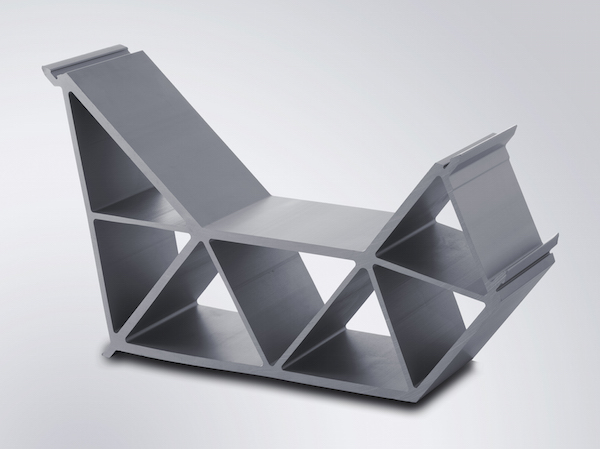

The company has also invested in a new large-scale friction stir welding (FSW) machine at its Finspång plant in Sweden, offering single- and double-sided welding of extruded aluminum profiles, produced as 18 x 3.5 m panels, which can be curved as well as flat. This FSW machine, which will become fully operational in October 2016, is the largest in Europe and one of the largest in the world.

FSW is a refined, advanced joining process in the production of aluminum car bodies for trains. The process joins metal surfaces through the effects of a rotary tool, pressure, and heat. No filling material is needed, and FSW provides better mechanical properties and less heat deformation than other forms of welding. Double-sided welding is faster and generally produces higher quality results than single-sided welding.

“The combination of friction stir welding and the fact that we deliver a finished component with all the necessary fabrication and processing completed, makes it simpler and quicker to construct the entire car body,” says Bruno D’hondt, managing director of Sapa’s extrusion activities in the Benelux region.