Hansens Aluminum LLC, a family-owned company based in South Africa, plans to build an $18.4 million aluminum extrusion manufacturing facility in Henderson, Kentucky. Hansens manufactures over 25 million anti-vibration and HVAC line fitting components for the automotive industry annually, which the company exports around the world, including Germany, China, and Mexico. The new Kentucky facility, which is scheduled to start production in 2017, will enable the company to expand its offering of precision components for the automotive sector for delivery throughout the U.S. and Mexico.

“We see great opportunities to supply our existing customers from Kentucky and to add new clients. The Henderson operation will expand our global capacity and allow us to add new automotive products to our range,” said Jared Pudney, business development manager for Hansens. “The support we have experienced at a local and state level from both elected officials and economic developers has been truly exceptional. This certainly influenced our decision towards Kentucky.”

Hansens has been working with the Kentucky Network for Development, Leadership and Engagement (Kyndle) to develop the project, choosing Henderson due to its central location as well as incentives provided by the state of Kentucky.

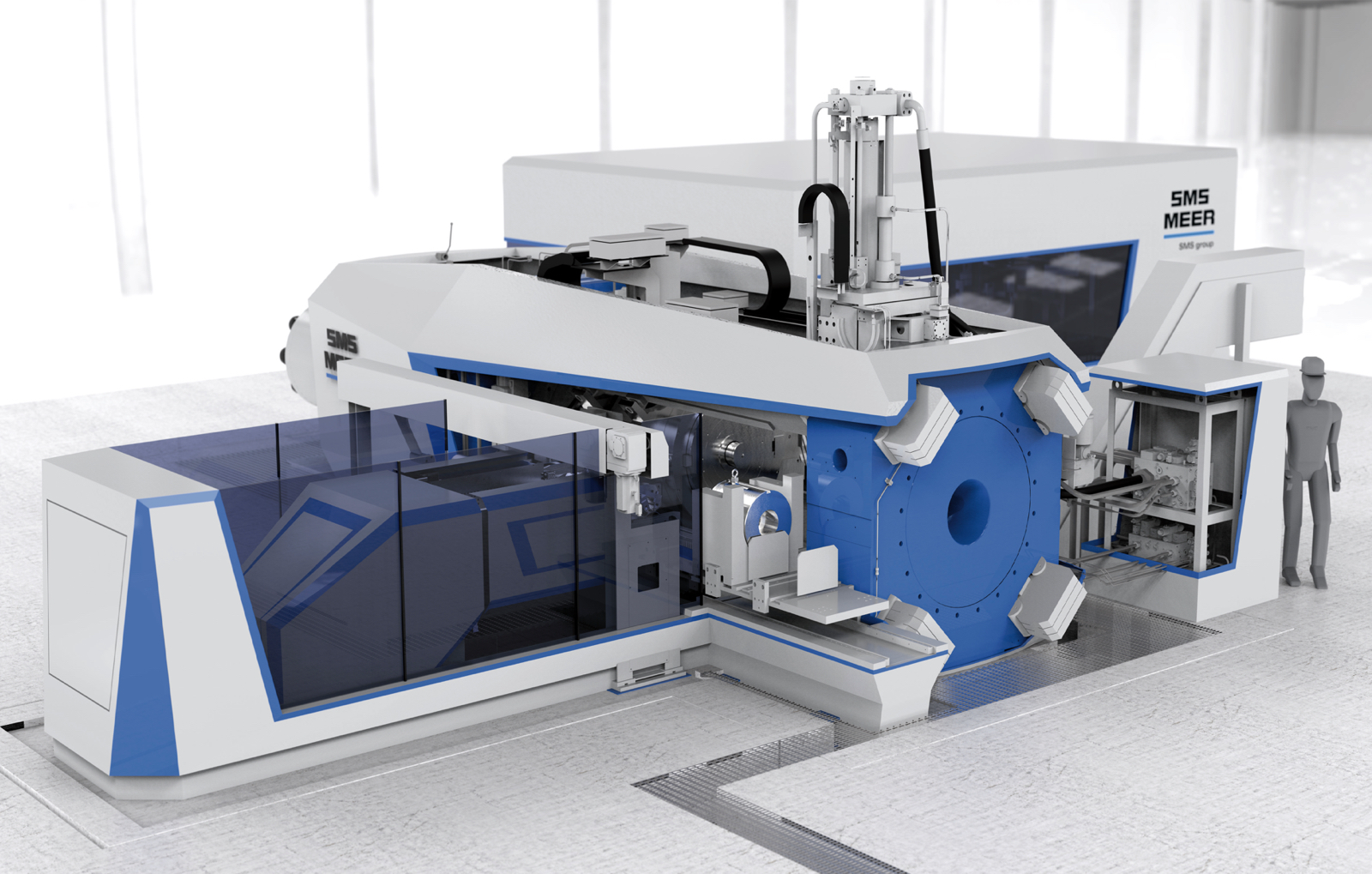

The 75,000 sq ft facility will include both aluminum extrusion and machining operations. Hansens ordered a state-of-the-art extrusion line from SMS group and OMAV SpA. The facility will be the first in the U.S. to install the SMS Hybrex® press, a next generation extrusion press that utilizes a new hybrid drive for energy-efficient production. According to SMS, owners of Hybrex benefit from energy savings in the range of 35-55%, depending on the field of application.

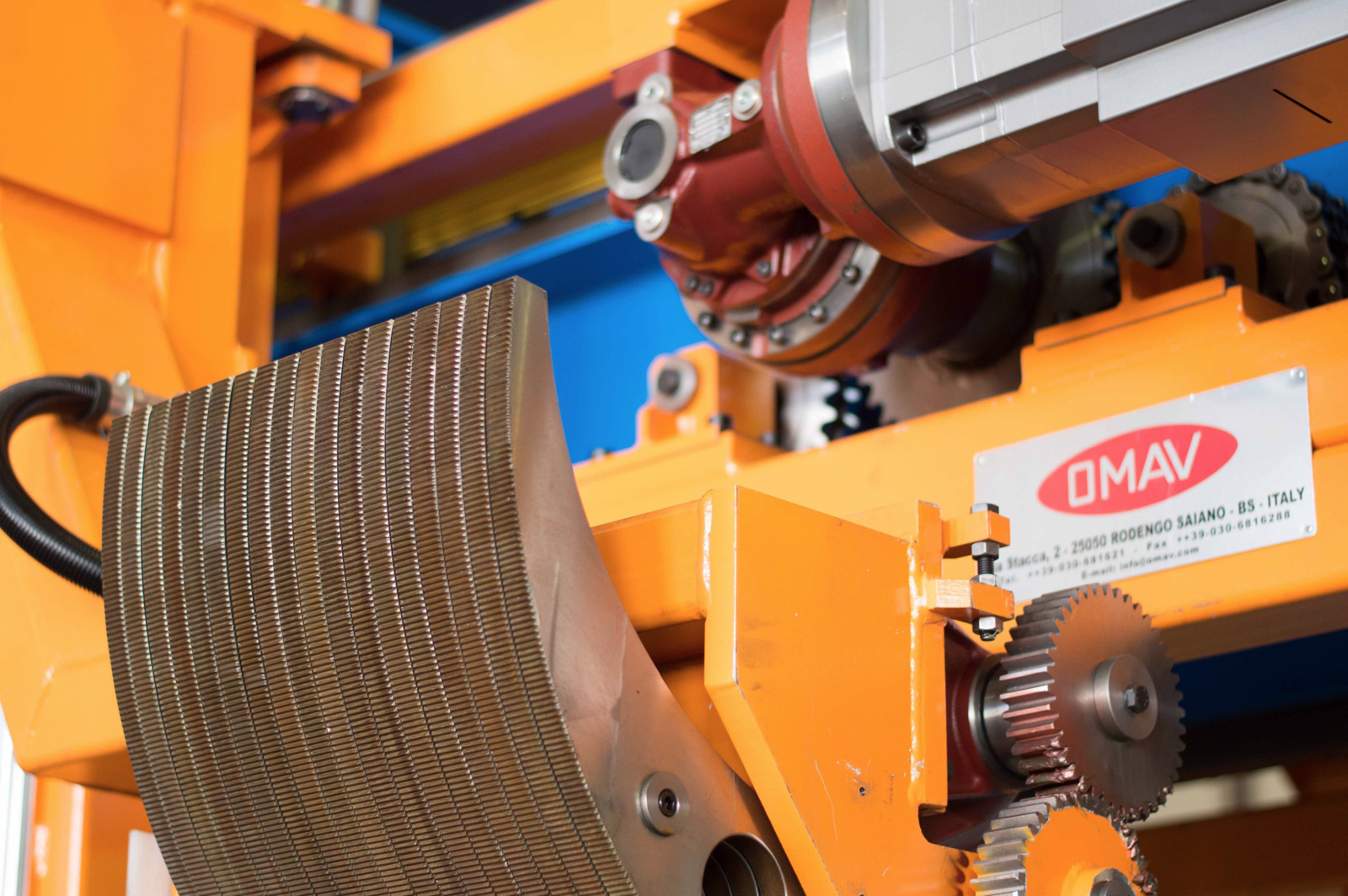

The handling systems for the new press line will be supplied by OMAV including a high efficiency pre-heating furnace, a process optimized cooling system, and OMAV’s innovative Direct Drive ePuller. The ePuller, which has been specifically engineered to work as an integrated solution with the Hybrex press, is one of the most energy efficient machine systems to guide extruded profiles from the press to the exit handling, according to OMAV.