The ET Foundation announced the winners of the 2021 International Aluminum Extrusion Design Competition. More than 100 students competing from 40 universities, colleges, design schools, and high schools from 15 countries around the world entered their designs. Winners were awarded a total of $13,500 in cash scholarships for their ingenious, multi-functional designs. The competition was sponsored by three Aluminum Extruders Council (AEC) members — Almag Aluminum Inc. in Brampton, Ontario, Canada; MI Metals, Inc. in Oldsmar, FL; and Pennex Aluminum Company LLC in Wellsville, PA.

The entries were reviewed and evaluated by a group of judges from the aluminum extrusion industry, including Todd Boyer, director of Sales and Marketing, Mid-States Aluminum; Joe Jackman, president, Almag, Inc.; Brook Massey, president, MI Metals; and Craig Werner, president, Werner Extrusion Solutions, LLC.

Design Awards

First Place

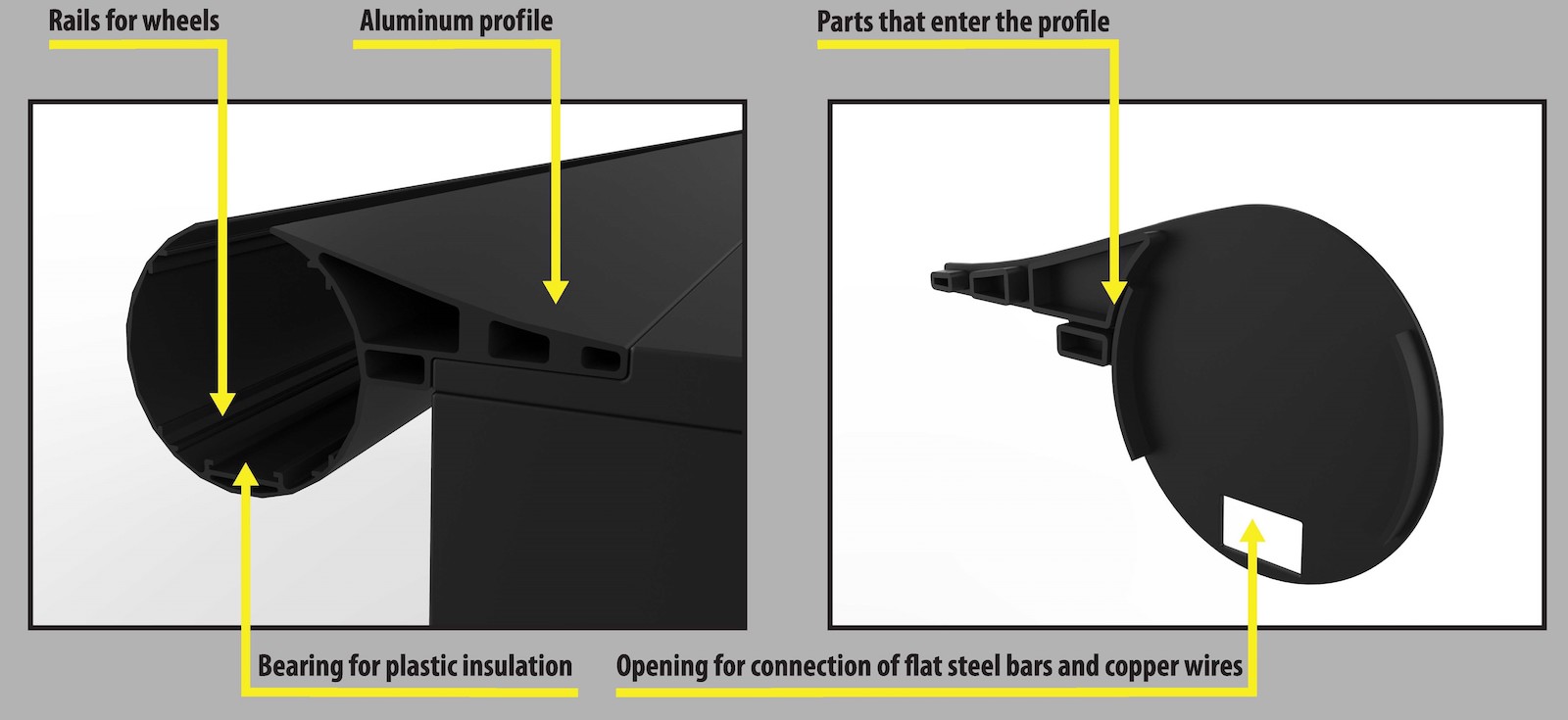

First Place, with a $5,000 scholarship, was awarded to Predrag Porobic, a senior design student at Megatrend University in Igalo, Herceg Novi, Montenegro, for his “Electric Rail” computer and drawing desk (Figure 1). The Electric Rail desk is designed for industrial, graphic and interior designers, architects, and engineering professionals. The desk employs linear motion to easily maneuver monitors and lighting accessories with a specially designed extruded aluminum chase system to stow cables and cords (Figure 2).

Several extruded aluminum brackets fit inside the profile to connect and attach accessories. The 15 cm bracket slides inside the aluminum profile along recesses intended for its wheels. The bracket’s three tube holes run to the base, with two holes for electrographite brushes that conduct current between monitors, lamp, and case. The main aluminum profile is screwed in place along the entire desk structure and incorporates rails upon which the bracket wheels move. The desk drawing board inclines at varying angles, and its computer and drawing surfaces are connected from one part, which is why the desk structure contains welded parts under the drawing surface.

“The aluminum profile, aluminum bracket, and metal tube with plastic articular rotators enable the height and angles to be adjusted,” explained Porobic. “Since this product is based on linear motion, aluminum profiles play a key role. One larger profile follows the length of the desk, and a smaller profile sits inside the large profile—two smaller profiles for monitors and one for the lamp. By merging the profile with the worktop, thanks to fluid and rounded surfaces, one gets the impression that the worktop and the aluminum profile form one element, although they are two different elements and materials.”

Werner commented, “This entry capitalized on many design advantages of aluminum extrusions: putting metal where it is needed; ease of finishing options, such as anodizing; aluminum extrusion’s strength for mounting purposes; and the ability to incorporate multi-functional parts into a single extrusion. The interactions of the wheels allow the inner extrusion to be easily repositioned throughout the length of the outer extrusion. Aluminum extrusions enabled Predrag to incorporate adjustability and functionality, with the possibility of limiting electrical cords for a cleaner, organized workspace.”

Second Place

Second Place, with a $4,000 scholarship, was awarded to Valeriia Shveikina, a student at Jan Evangelista Purkyně University in Ústí nad Labem, Czech Republic, for her HORAE temporary wall screen (Figure 3). The wall screen utilizes an integrated potted plant mounting system made of extruded aluminum profiles fixed between the floor and ceiling, as well as plant holder profiles for mounting potted plants, which enables a greener indoor environment.

Three aluminum extrusions form the design: one profile for the wall system, one for the flowerpot holder, and an angled profile for the mounting system. Shveikina’s choice of aluminum extrusion enables the design of a long profile with interior grooves on which the flowerpot holders can freely move. The holder’s two halves attach to the wall separately, allowing pots of differing sizes, with varying heights and distances between planters. “The system can be used in homes and businesses to subdivide space elegantly and without much intervention,” noted Shveikina. “It is a subtle wall that makes interiors more interesting and stylish and brings you closer to nature.”

Boyer stated, “The ability to configure an extruded aluminum wall screen for use in commercial and residential environments was both functional and attractive. Adding green space on one side makes the ‘ordinary’ wall screen something very special. The unit also provides portability so often needed in offices, restaurants, and homes.”

Werner commented, “Valeriia designed interlocking parts with just a few extruded profiles. What drew me to this design was the concept’s modularity, allowing single units to be used or multiple uprights combined into linear, curved or other creative forms. Modularity and the ability to provide the product in various anodized, painted, or even mill finishes enables designers to utilize these to enhance interior spaces.”

Third Place

Third Place, with a $3,000 scholarship, was awarded to Pierre-Olivier Santerre, a student at Dawson College in Delson, QC, Canada, for his BAKS chair (Figure 4). The chair highlights aluminum and the extrusion process in a design that is durable, comfortable, and easy to assemble. The ash wood and aluminum chair has a mid-century modern aesthetic, with extruded aluminum profiles forming the back, front and top spar, and legs. The leg extrusions utilize bending and the spar profiles include screw bosses, optimizing extrusion’s ability to integrate features and eliminate fabrication steps. Aluminum was chosen for its natural color and multiple finish options. Extruded aluminum comprised 90% of the parts, making an easy-to-manufacture, lightweight, and sustainable chair.

“The design is attractive and I could see this [chair] being used in reception areas and in doctors’ offices,” said Massey.

Jackman concurred, noting, “By mixing wood with the aluminum extrusion, Pierre-Olivier has come up with a beautiful, modern, sturdy, and lightweight chair. The bent legs show how versatile and ductile aluminum extrusion is, and the incorporated screw bosses allow for minimal fabrication and ease of assembly.”

Sustainable Design Award

The Sustainable Design Award acknowledges a design’s market potential, practicality, product/process improvement, and creativity, while simultaneously addressing environmental concerns or improved quality of life. Since no single entry adequately addressed all of these criteria, the judges awarded three honorable mentions, each of which received a $500 scholarship.

Agricultural Robot

Sanat Seitov from Lomonosov Moscow State University in Moscow, Russia, received an honorable mention for his agricultural robot (Figure 5). The agricultural robot detects and combats plant diseases by collecting information in farm fields on plant health and providing subsequent treatments. The robot’s extruded aluminum modular design is lightweight and easy to assemble, offering lower repair costs and reduced manufacturing complexity.

“A farmer can give remote commands to robots working in several large fields for 16 hours a day without recharging,” noted Seitov. “Farmers may realize increased profits and reduced risk of crop failure by analyzing the condition of plants using this automatic device that protects the health of cultivated plants with low specific ground pressure that saves the soil structure and does not change the soil’s water and air regime. The pressure is less than that of tractors, since the mass is lower due to the robot being made from aluminum.”

Massey noted that the design was well conceived. He said, “The reduction of chemical usage could be huge for the environment and a great cost savings for farmers.”

Werner added, “Sanat’s fascinating design is based on aluminum extrusions providing a strong, stable, corrosion-free framework. The design has the ability to meld technologies of vision systems, artificial intelligence, and GPS to further modernize farming. The use of minute, targeted pesticides versus broadcast spraying would provide immense environmental and health benefits.”

Assistive Shower Seat

Kevin Zhao from Rochester Institute of Technology, School of Design in Rochester, NY, received an honorable mention for his Showfold shower chair (Figure 6). The shower chair is an assistive shower seat device with an easy, two-step installation in the bathtub for help with balance in the shower.

“The aluminum extruded seat and legs allow the chair to be lightweight and non-corrosive,” noted Zhao. “Simple aluminum extrusions enable the product to be easily mass produced and assembled to lower production time and cost. The aluminum enables the chair to be extremely weight bearing, making it accessible to people of all sizes. For safety, the seat is set at an angle to prevent the suction-cupped legs from moving in the tub for a non-slip, worry-free experience. The legs have a 90-degree locking mechanism that ensures optimal stability.”

Erosion Control System

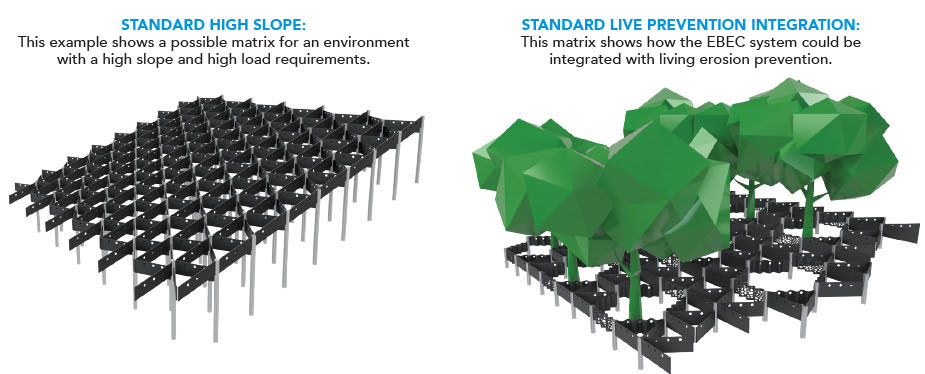

Will Asproth, a high school student and aspiring aerospace engineer at the University of Minnesota, College of Science and Engineering in Chaska, MN, received an honorable mention for his Extrusion-Based Erosion Control (EBEC) system (Figure 7). This EBEC system is designed to alleviate water- and gravity-based soil erosion. “The two-part system consists of one part that slows down and redirects surface water, and another part that prevents sections of earth from separating,” noted Asproth. “The design uses submerged plates to prevent surface erosion and long rods to prevent mass-movement erosion. The plates and rods interconnect to form a matrix that protects the shape of the earth. While the plates can be made from numerous materials, the best material for the matrix rods is aluminum.”

Aluminum extrusions can be formed into the correct shapes to connect the plates, making the system highly customizable and adaptable to any erosion environment. “An engineer could create custom matrices for any environmental conditions where erosion must be prevented,” explained Asproth. He chose aluminum alloy 6063, due to its favorable extrusion characteristics, high strength, and relative abundance in recycling. Six different plates were designed for various environments, including high-slope areas and regions where water pass-through is preferable. The varied length extruded aluminum stakes, together with the plates are the building blocks for the EBEC system.

Werner observed extensive construction work to limit or correct the effects of shoreline bluff erosion along the Southern California coast. He noted, “With climate change comes alternating periods of drought and intense rain. Without the ability of longer or deeper root vegetation to help stabilize bluffs or hillsides, the drier soil is easily washed away. Will’s solution may help stabilize the soil to allow vegetation to ‘take root’ more securely or otherwise help control and direct water flow, reducing the devastation caused by erosion.”

Editor’s Note: For more information on the International Aluminum Extrusion Design Competition, visit: www.etfdesign.org.

This article first appeared in the June 2021 issue of Light Metal Age. To receive the current issue, please subscribe.