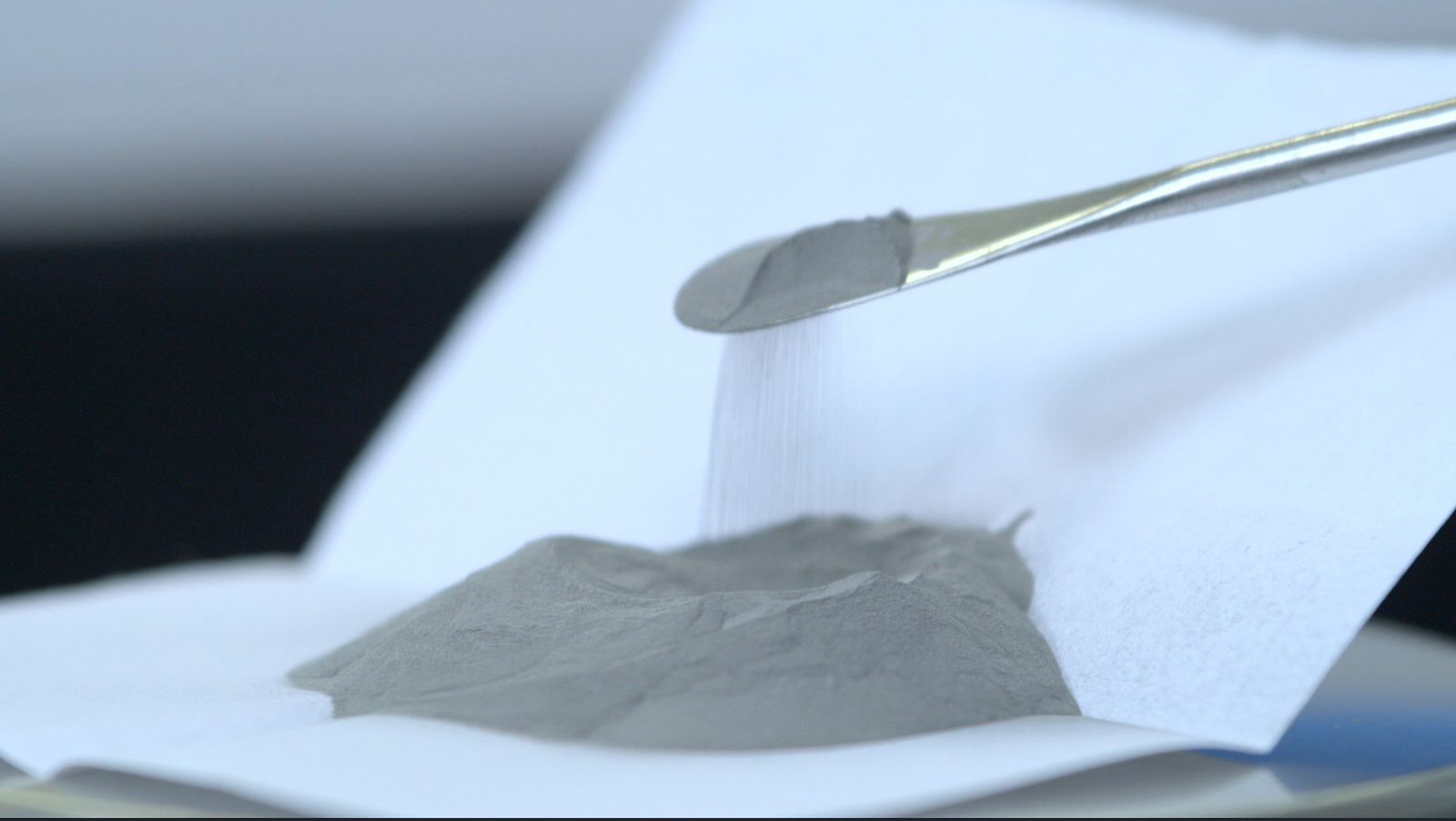

Sintavia, LLC, a leader in the metal additive manufacturing industry, developed full end-to-end parameters for producing 3D printed parts in F357 aluminum, as well as other Al-Si alloys, for use in precision manufacturing. The proprietary process for printing F357 aluminum powder was developed specifically to address aerospace and automotive industry needs for components with low density, good processability, and heat conductivity. Though most aluminum alloy parts are manufactured using traditional casting practices, the company aims to change the landscape for industries looking to expand beyond traditional manufacturing in foundry-grade aluminum alloys.

“We are seeing an increased demand for additively manufactured Al-Si parts from both the aerospace and automotive industries,” says Doug Hedges, Sintavia’s president and COO. “With Sintavia’s comprehensive manufacturing capabilities, we have developed processes to make F357 aluminum specimens and quickly test them to demonstrate they meet or exceed these industries’ strict validation parameters.”

Sintavia’s exclusive processes are designed to meet critical engineering requirements at every step. By establishing a procedure that not only includes pre-build material analysis, but also post-production heat treatment and stress relief, the company is able to produce additive manufactured components proven to exceed original design strength by up to 125% at net densities of near 100%. Through the performance of strength validation at ambient, elevated, and subzero temperatures, Sintavia is capable of part validation in all critical environments.

Increasingly, OEMs are demanding — and achieving — reduced cycle times and improved quality from their manufacturing supply chains. Sintavia is working to answer this call for critical manufacturing by leveraging the speed benefits of additive manufacturing, while offering elite powder analysis, post-processing, and mechanical testing on-site. According to the company, this combination of end-to-end speed, data security, and quality allows Sintavia to offer unprecedented manufacturing services to these important industries.