Nagoya University developed a new method that uses metal 3D printing to create a new aluminum alloy series optimized for high strength and heat resistance. The new alloys use low-cost, abundant elements, and are recycle-friendly. One variant is said to remain both strong and flexible at 300°C.

“The alloys also proved easier to 3D print than conventional high-strength aluminum, which frequently cracks or warps during fabrication,” noted Naoki Takata, lead author and professor at Nagoya University Graduate School of Engineering.

Developing Heat Resistant Alloys

Aluminum is prized for being lightweight and strong, but at high temperatures it loses strength. This has limited its use in automotive and aerospace engines, turbines, and other applications where parts must stay strong under high temperature conditions.

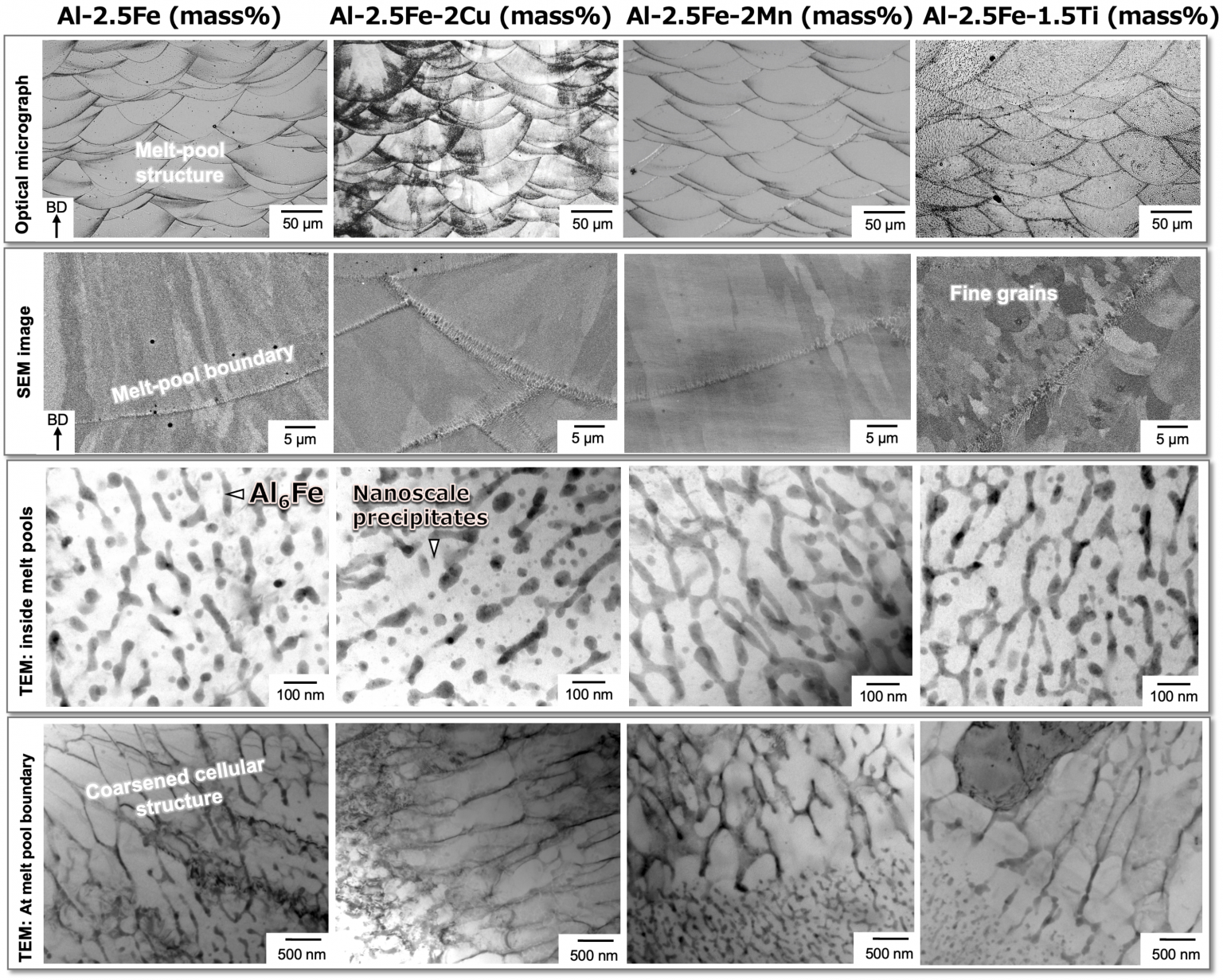

In response, the researchers developed a systematic method to predict which elements will strengthen the aluminum matrix and which will form protective micro or nano structures during the 3D-printing process. They tested these predictions by creating new alloys with copper, manganese, and titanium, and then confirmed the results through electron microscopy.

According to the researchers, the best performing alloy contains aluminum, iron, manganese, and titanium (Al-Fe-Mn-Ti), and outperforms all other 3D-printed aluminum materials by combining strength at high temperatures with flexibility at room temperature.

Notably, the use of iron in aluminum alloys is unusual, because it tends to make the aluminum metal brittle and increases the risk of corrosion. The 3D printing manufacturing method addresses this concern.

“Our method relies on established scientific principles about how elements behave during rapid solidification in 3D printing and is applicable to other metals,” explained Prof. Takata. “The extreme cooling rates in laser powder bed fusion, which is a representative process of metal 3D printing technologies, cause molten metal to solidify in seconds. This changes fundamental rules — the rapid cooling traps iron and other elements in arrangements (formation of metastable phases) that can’t form under normal manufacturing conditions. By carefully selecting which elements to add, we created new alloys that are both heat-resistant and strong.”

Expanding Vehicle Lightweighting

The new aluminum alloys developed by Nagoya University could enable lightweight aluminum components in parts that operate at elevated temperatures, such as compressor rotors and turbine components. Lighter vehicles consume less fuel and produce fewer emissions.

The aerospace industry may also benefit, as aircraft engines require materials that combine light weight with heat resistance. Beyond these applications, the research provides a framework for designing new classes of metals specifically for 3D printing, with potential to accelerate development across multiple industries.

For more information, read the paper, “Design of high-performance sustainable aluminum alloy series for laser additive manufacturing,” by Naoki Takata, Koki Minamihama, Takanobu Miyawaki, Yue Cheng, Yifan Xu, Wenyuan Wang, Dasom Kim, Asuka Suzuki, Makoto Kobashi, and Masaki Kato, published in Nature Communications in 2025.