Aluminum- and metal-based additive manufacturing (AM) has a need for collaboration between hardware equipment manufacturers and material providers to address customer problems. In order to solve these challenges, Elementum 3D and SLM Solutions have agreed to collaborate on the design of exclusive aluminum alloys on SLM® technology. In this way, both companies are teaming up to further enhance material offerings used to 3D print end-use parts traveling to space.

“We are pleased to announce this working agreement with SLM Solutions,” said Jacob Nuechterlein, president and founder of Elementum 3D. “With Elementum 3D’s ground-breaking materials and SLM Solutions leadership in production-sized printers for aluminum, we can offer a full solution to organizations ready to take their ideas to production.”

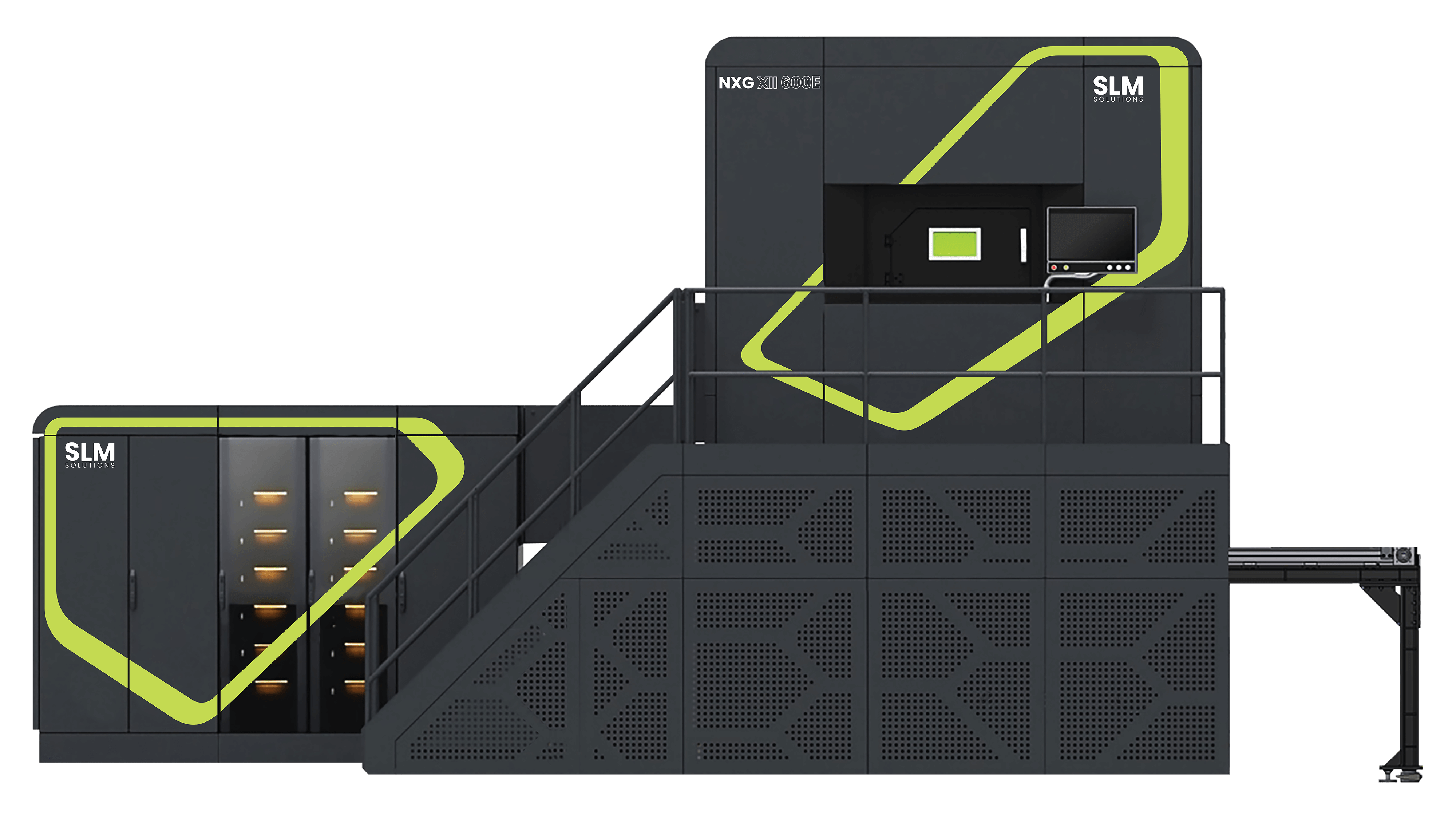

SLM Solutions recently announced its new NXG XII 600E, a 12-laser additive manufacturing machine that provides a larger manufacturing envelope and greater flexibility. The company has already accepted an order for the new machine from Concurrent Technologies Corporation (CTC), the prime contractor for a U.S. Air Force Research Laboratory (AFRL) project.

SLM Solutions systems are based on an open architecture strategy that allows users to have a free choice of materials, adapt parameters as required, and have variable control on all levels of the process. The NXG XII 600 (precursor to the 600e pictured here) thus paves the way for a whole new level of metal-based additive manufacturing, enabling productive part production at reduced cost per part.

However, despite these kinds of advancements in new equipment, the lack of material options remains a lingering challenge. This is a key to unlocking high-performing parts with high-performance material requirements. The aerospace and space industries are eager to integrate new materials, but have faced various challenges with highly sought-after lightweight aluminum alloys that are difficult to print, as they are prone to cracking. Nevertheless, these alloys are used due to their versatility, high strength, and corrosion resistance — a real pain point for the aerospace industry.

As a result, Elementum 3D and SLM Solutions are working together to develop new aluminum alloys, including 2024 and 6061 and aerospace grade 7050 and 7075 for SLM machines in 2023. Within the start of a joint development agreement, Elementum 3D acquired the SLM NXG XII 600 from SLM Solutions. This equipment will be used to test new alloys with the aim of expanding the use of additive manufacturing and increasing the exposure of the company’s materials. The collaboration will also give further impetus to the NXG XII 600 and will lead to even more innovative, additively manufactured, high-quality parts.

“This strong partnership will enable our goal of empowering our customers to achieve theirs,” said Sam O’Leary, CEO of SLM Solutions. “It will pave a path for an enhanced material portfolio enabling better-performing applications and new business cases. We look forward to this partnership achieving new heights in AM and accelerating an idea-to-production platform for our customers.”