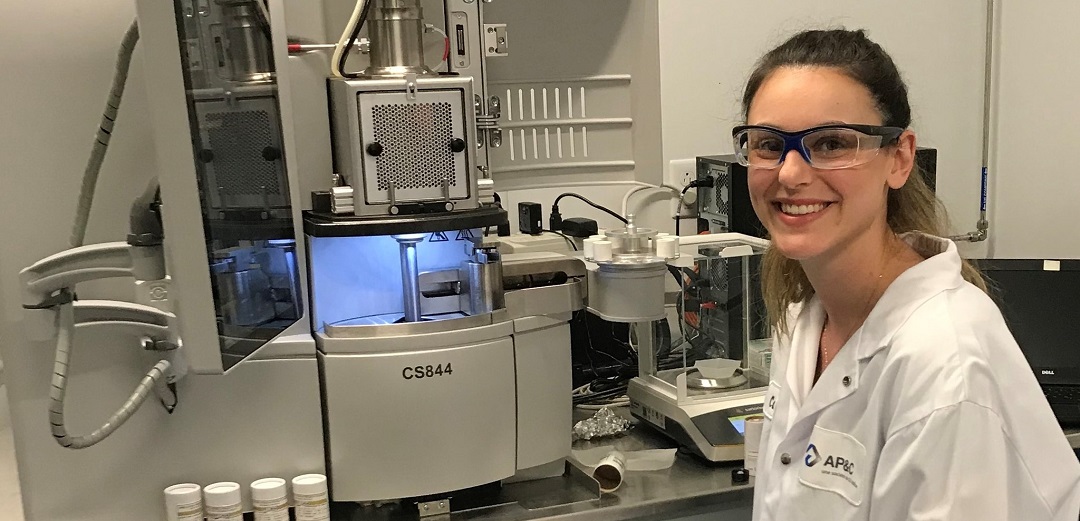

AP&C, a GE Additive company, will begin production of F357 aluminum alloy powder for the additive manufacturing industry. The powder will be produced using AP&C’s proprietary Advanced Plasma Atomization (APA™) technology at its recently expanded facility in Saint-Eustache, Canada. This new, automated plant offers a full aluminum powder production capacity of 1,000 tons.

The new F357 aluminum alloy powder has the same quality signature as APATM titanium powders — including good processability, high flowability, high packing, low porosity, and high purity — which are all required by the additive manufacturing industry to enhance performance and reliability of the aluminum printing process. The F357 alloy is increasingly in demand from customers in the aerospace and automotive sectors, as it is known to have good weldability, high strength, and toughness along with offering a good corrosion resistance and heat conductivity. The aluminum powder maps well with AP&C’s existing product range and experience working with reactive and low density metals.

“It’s great to add aluminum F357 to our portfolio. Our customers have been asking us to provide aluminum solutions to address the challenges they currently experience. We are confident we’ve developed a solution that solves these challenges,” said Alain Dupont, president and CEO of AP&C. “The modular cell-based structure of our new plant in Saint-Eustache allows us to respond quickly to the additive industry’s demands as it rapidly evolves.”

Customer deliveries of the new aluminum alloy powder are expected to begin in April 2019.