Cover

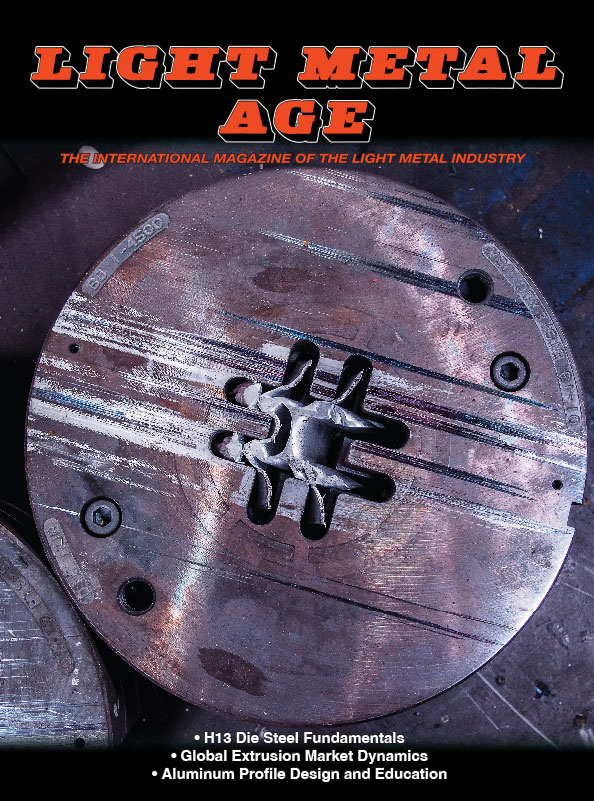

The sheared face of a “hub” extrusion die used to connect several drawn tubes together to form a tent system. This is the first die that was run at the Alfiniti drawn tube operation in Winton, NC. Alfiniti expanded through investment in equipment to supply their internal tube bloom feedstock. See story beginning on page 6. (Photo by J.D. Schloz)

Articles

Alfinity Winton Expands Drawn Tube Operation: Invests in 3,000 Ton Chinese Extrusion Press Line

By J.D. Schloz

Page 6

Purchase Article

The Puller as Enabler of Productivity in Aluminum Extrusion

By Roy Hollis

Page 12

Purchase Article

Spanish Extruder Thrives in Difficult Market

Page 22

Purchase Article

Metallurgical Fundamentals Applicable to H13 Steel Dies Used in Aluminum High Pressure Die Castings and Extrusion

By Joseph C. Benedyk

Page 26

Purchase Article

Designing with Aluminum Extrusion, Part I

By Craig Werner

Page 36

Purchase Article

Fair Trade for Aluminum Extruders in North America: Where Have We Been & Where Are We Going?

By Rand Baldwin

Page 42

Purchase Article

First Extruder in Gulf Maintains Leadership Position While Expanding and Responding to Market Dynamics

Page 46

Purchase Article

Engineering and Designing Aluminum Structural Solutions: Interview with Alexandre de la Chevrotiere, CEO of MAADI Group

Page 50

Purchase Article

Interview with Bonnie Cartwright, Exco Technologies: Established North American Die Maker Continues Robust Growth into South America

Page 58

Purchase Article