Different metals have their own individual conductive properties for electric current and heat. Aluminum is one of the best performing metals for both purposes. Copper is an even better conductor, however it is much heavier and significantly more expensive. DODUCO GmbH, based in Pforzheim, Germany, has been focused on developing ways of combining both materials in order to unleash new technological possibilities. To this end, the company developed two hybrid metal bonds through a high-tech fusion of copper and aluminum, including:

- Overlapping Bonds – metal strips, i.e. copper on the right side and aluminum on the left

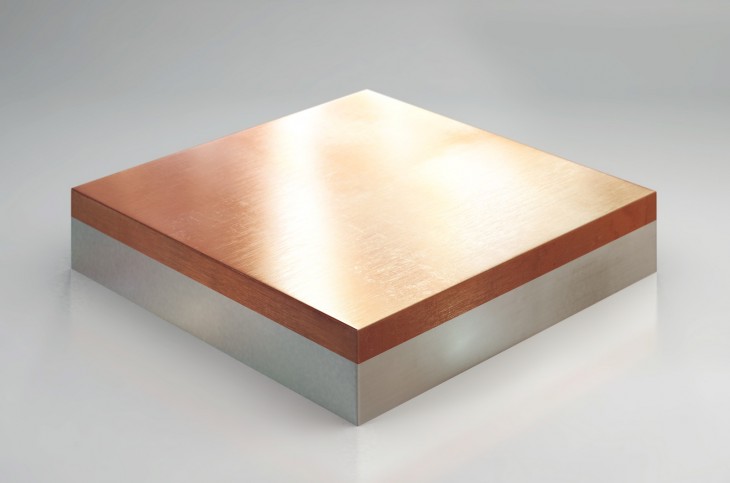

- Surface bonds – metal plates, i.e. copper on top and aluminum on the bottom used in the manufacture of high performance heatsinks or substrate parts

Modern automobiles increasingly implement aluminum as an electrical conductor. In today’s cars, most of the electric cables are made out of aluminum. The cross section of the aluminum components required to conduct the same amount of electricity is about 1.6 times greater than copper, but in comparison aluminum weighs only half as much. Unfortunately, not every copper part can be replaced by aluminum, as aluminum is can sometimes bend and slip under mechanical stress, which can cause screws or crimp connections to come loose. These properties create the need for a reliable transition between copper and aluminum components.

DODUCO’s solution is a hybrid material in which the expensive copper material is partially replaced by cheaper and lighter aluminum. The company is able to firmly bond the two metals through a cold rolling process and cement the bond in a hot oven. The lightly overlapping boded materials are used in electric mobility applications for lithium-ion batteries in electric cars or as connectors on aluminum wiring harnesses. With overlapping metal layers, widths of up to 100 mm and a thickness of up to 3 mm can be produced. At the same time, the company has been able to create a copper and aluminum bond that enables the product to withstand high tension and compression under extreme temperatures without failing.

A key challenge is protecting the hybrid material from corrosion — a vital aspect in automotive applications. The company uses a special organic coating to protect the metals from moisture and salt. The company also uses special innovative organic and inorganic coatings to protect the metals from damage from moisture and saltwater.

In contrast to the overlapping bonds, the surface-bonded material hybrids are primarily used as heatsinks for high power electrical applications. Modern automotive vehicles use more and more high energy electronics, which create a lot of heat. A hybrid material of copper and aluminum enables the development of heatsinks with higher conductivity. In metal plate form, the hybrid material can be produced with a width of up to about 200 mm, and the thickness of the Al/Cu layers can be tailored to any required specifications up to a total thickness of up to 10 mm.

“OEMs have shown a strong interest in our materials,” remarks Kuntz. “The new technology offers a number of different usage and combination possibilities.”