Latest

-

Jupiter Aluminum Industries (JUPALCO), part of the Jupiter Group, placed an order for two additional Vortex furnaces for aluminum coil annealing from SECO/Warwick. The company was established in 2023, with the first three coil annealing systems supplied at that time. “Two years ago, we chose three Vortex 2.0 systems, which at the time fully met […]

-

EGA Spectro Alloys signed a major contract with Presezzi Extrusion for the supply of key scrap recycling equipment. This marks an important milestone in the company’s ongoing commitment to advanced aluminum processing technologies. “Our partnership with Presezzi Extrusion will bring best-in-class technology to Spectro’s operations and strengthen our ability to deliver consistent, high-quality billet to […]

-

Century Aluminum and Emirates Global Aluminium (EGA) selected American firm Bechtel to conduct preparatory engineering for their planned primary aluminum production plant in Inola, Oklahoma. “Building the first American primary aluminum production plant in decades is a transformative project for America’s industrial revival, the strong economic future of Inola and Oklahoma, and for our company,” […]

-

Rio Tinto and Aluminum Corporation of China Limited (Chalco) entered into a definitive agreement to jointly acquire Votorantim’s 68.596% controlling share of Companhia Brasileira de Alumínio (CBA). Under the agreement, Rio Tinto will own 33% of shares and Chalco will own 67%. “This acquisition, jointly with Chalco, of Votorantim’s controlling position in CBA’s fully integrated […]

-

Tahweel Metal Industry Corporation (TMIC) plans to construct a fully integrated, state-of-the-art aluminum foil plant in Dammam, Saudi Arabia. The announcement ceremony, which took place in Riyadh, was attended by government officials, as well as company and supplier representatives. Established in 2022, TMIC is the first integrated aluminum foil producer in the Middle East and […]

-

PSW Group, a global leader in high-quality, low-carbon aluminum and magnesium products, officially opened its High Integrity Diecasting Center (HIDC) at the Magretech plant in Bellevue, Ohio. The more than $3 million investment places semi-solid casting R&D, engineering, and prototyping at the core of PSW’s strategy to accelerate low carbon, high integrity light metal innovation. […]

-

Century Aluminum Company and Emirates Global Aluminium (EGA) entered into a joint development agreement to build the first new primary aluminum production plant in the U.S. since 1980 — revitalizing U.S. aluminum expertise and know-how. Previously, the two companies had each separately announced plans to build smelters in the U.S., including EGA’s planned greenfield smelter […]

-

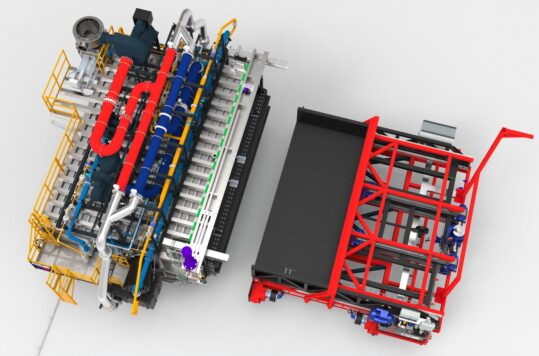

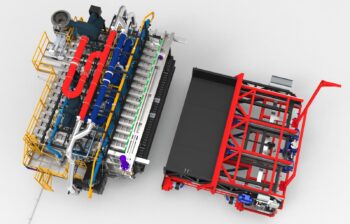

Kubikenborg Aluminium AB (KUBAL), Sweden’s only primary aluminum producer, is taking a transformative step toward sustainable and circular production with the planned installation of a new remelting plant (Figure 1). Supported by the Swedish Energy Agency, the new facility will enable the company to recycle aluminum scrap, lower its energy consumption, and improve the flexibility […]

-

Nagoya University developed a new method that uses metal 3D printing to create a new aluminum alloy series optimized for high strength and heat resistance. The new alloys use low-cost, abundant elements, and are recycle-friendly. One variant is said to remain both strong and flexible at 300°C. “The alloys also proved easier to 3D print […]