Cover

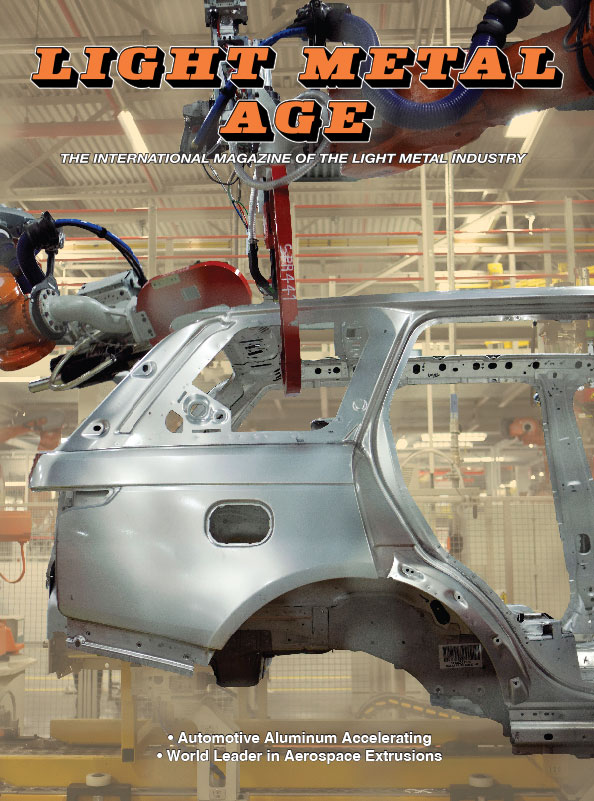

Assembly of the all-new Range Rover at the Jaguar Land Rover manufacturing facility in Solihull, U.K., showing the aluminum stamped side structure. The 2013 Range Rover is now the first SUV with an all-aluminum body structure. Novelis supplied AC-300 alloy aluminum sheet for body structural components in crash relevant areas, including the longitudinal beams in the front end assembly, the reinforcements of the underbody, and structural components in the rear end of the vehicle. For more information about the use of aluminum in the new Range Rover, and other light vehicles, see page 32. (Photo: ©Jaguar Land Rover)

Articles

New Global Technology Center for World Leader in Supply of Aerospace Extrusions and Components

Page 6

TMS 2012: Selected Topics in Aluminum Reduction Technology

By Rudolf P. Pawlek

Page 14

Weighing Material Options against Vehicle Fuel Standards: Global Automotive Lightweight Materials Detroit

By Joseph C. Benedyk

Page 24

Aluminum Growth in Automotive Applications: Interview with Roland Harings, VP of Novelis Global Automotive

Page 30

Aluminum Use Accelerating on the Road Ahead

By Andrea Svendsen

Page 32

Aluminum Moving into the Fast Lane for Automotive in North America: Interview with Dick Schultz, Ducker Worldwide

Page 36

The Goal of Optimizing Aluminum Extrusion Operations, Part VI: Linear Programming+, Or, Bill Becomes a Master of Extrusion Optimization

By Craig Werner

Page 40

Quench Sensitivity of Aluminum Alloys Used for Rail Vehicles

By Huang Zhi-qi, Zhou Xiang, Yin Zhi-Min, and Li Shenlan

Page 46

International Metal Quality Workshop in Dubai

Page 54

TMS 2012: Annual Meeting and Exhibition

Page 58

WEFA Celebrates its 40th Anniversary

Page 60

Longevity in Aluminum Engineering, Casting, Heating, and Automation: Gautschi at 90 Years

Page 62